Self-absorption tail gate lock body assembly

A tailgate lock and self-priming technology, which is applied in the field of automobile locks, can solve problems such as poor safety and large electromagnetic interference, and achieve the effects of reasonable structure, good safety, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, but not as limiting the present invention:

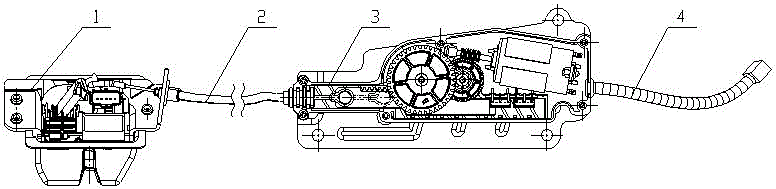

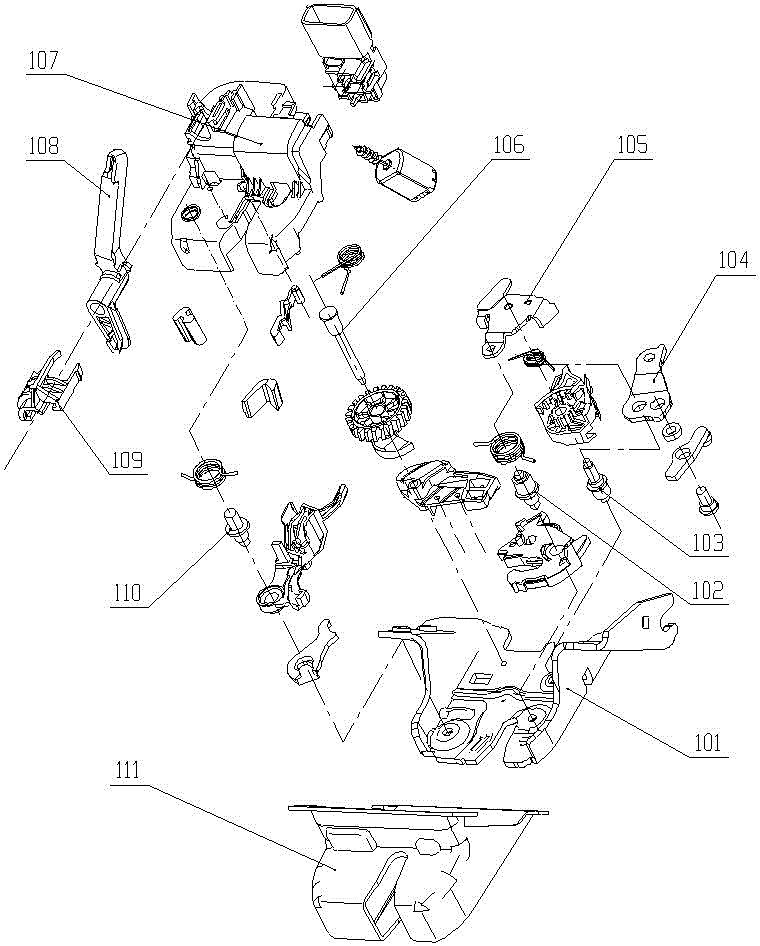

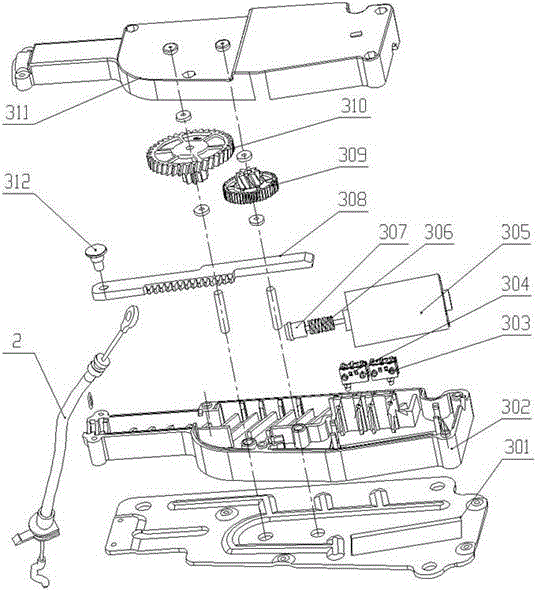

[0014] The self-priming tailgate lock body assembly includes a tailgate lock body 1 and a tailgate lock drive module 3, the tailgate lock body 1 includes a bottom plate 101, a shield 111 is arranged on one side of the bottom plate 101, and a lock body is installed on the bottom plate 101 107, the pawl shaft 110, the ratchet shaft 102, the gear shaft 106 and the self-priming rocker shaft 103 are respectively arranged on the horizontal surface of the middle part of the bottom plate 101, the pawl shaft 110 passes through the pawl linkage block in turn, and the pawl is connected with the bottom plate 101, The outer ring of the ratchet shaft 110 is provided with a ratchet return spring, one end of the ratchet shaft 102 is connected to the bottom plate 101 through the ratchet wheel, the outer ring of the ratchet shaft 102 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com