Rotary Hammer Drilling Tools

A drilling tool and percussion technology, applied in the field of rotary percussion drilling tools, can solve the problems of limited drilling speed and drilling efficiency, poor rock breaking ability of the drill bit, etc., achieve high rotational speed, improve torque transmission efficiency, increase drilling speed and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

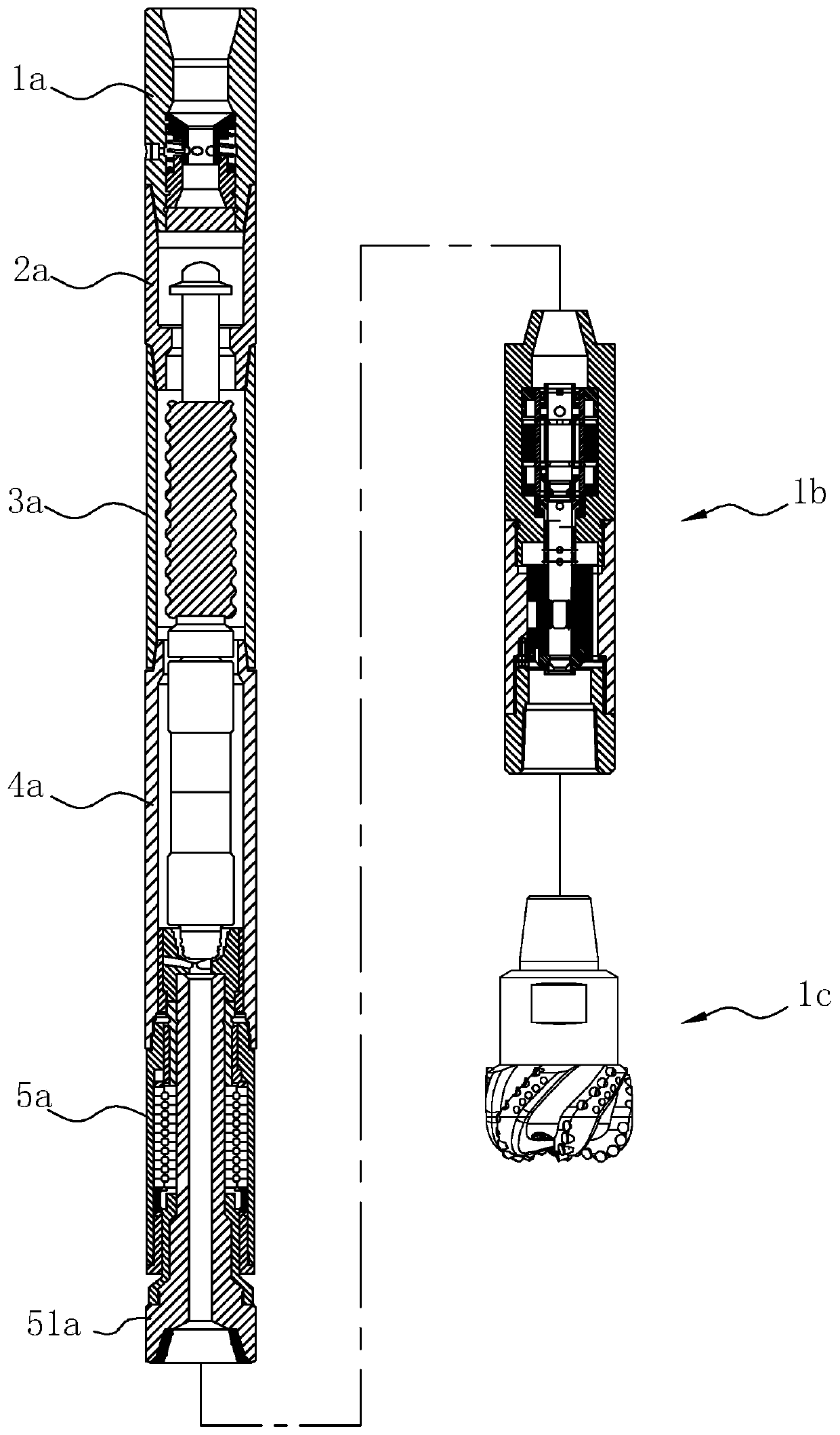

[0050] see figure 1 , a rotary percussion drilling tool, including a bypass valve assembly 1a, an anti-drop assembly 2a, a motor assembly 3a, a cardan shaft assembly 4a, and a drive shaft assembly 5a that are sequentially connected by threads, the above structure and The prior art is the same and will not be described in detail. The drive shaft assembly 5a includes a drive shaft 51a with a hollow channel, one end of the drive shaft 51a is threadedly connected with an impact device 1b, and the end of the drive shaft 1b away from the connection with the drive shaft 51a is threaded with a drill bit 1c. The drill bit 1c is a PDC drill bit.

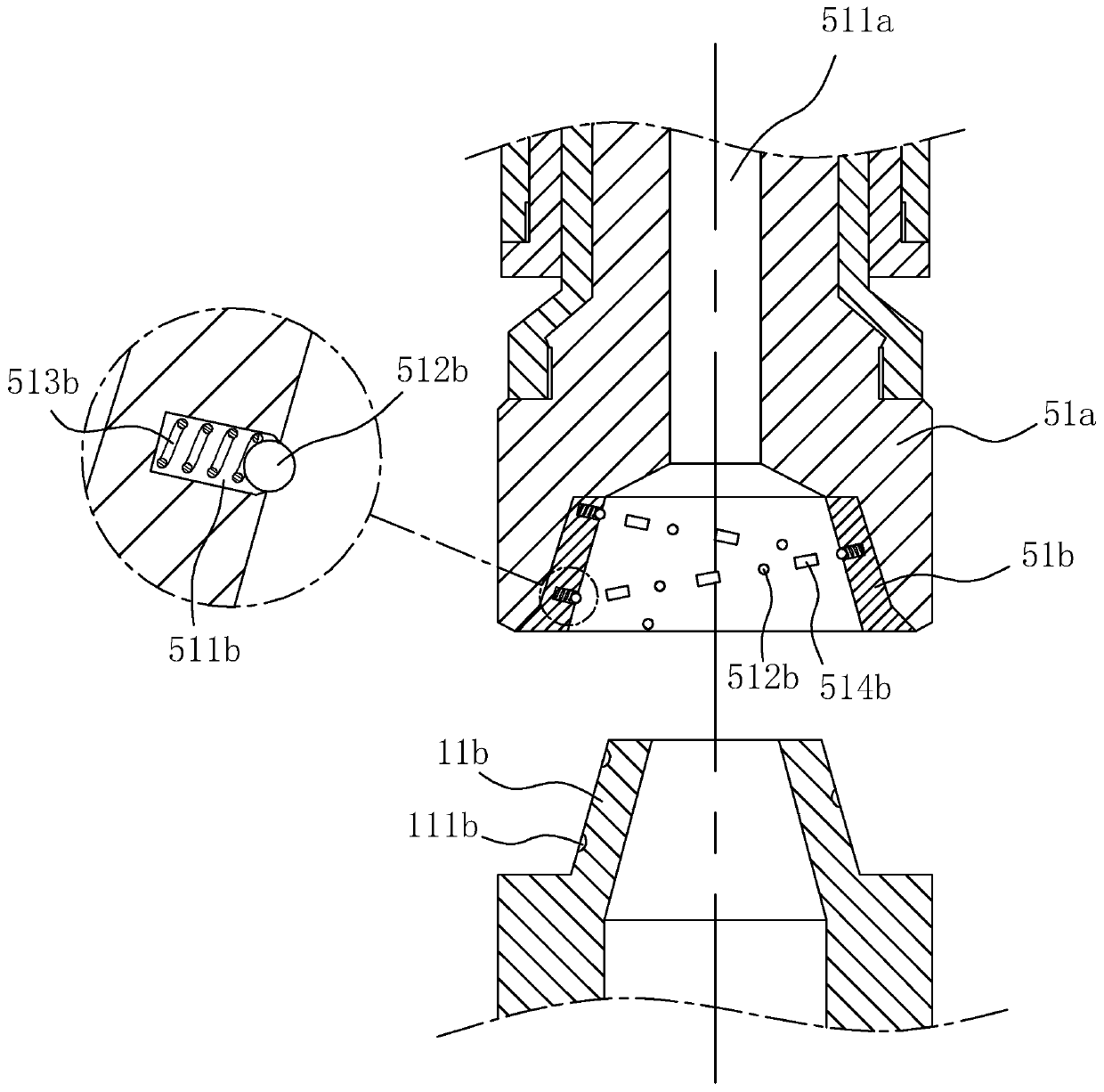

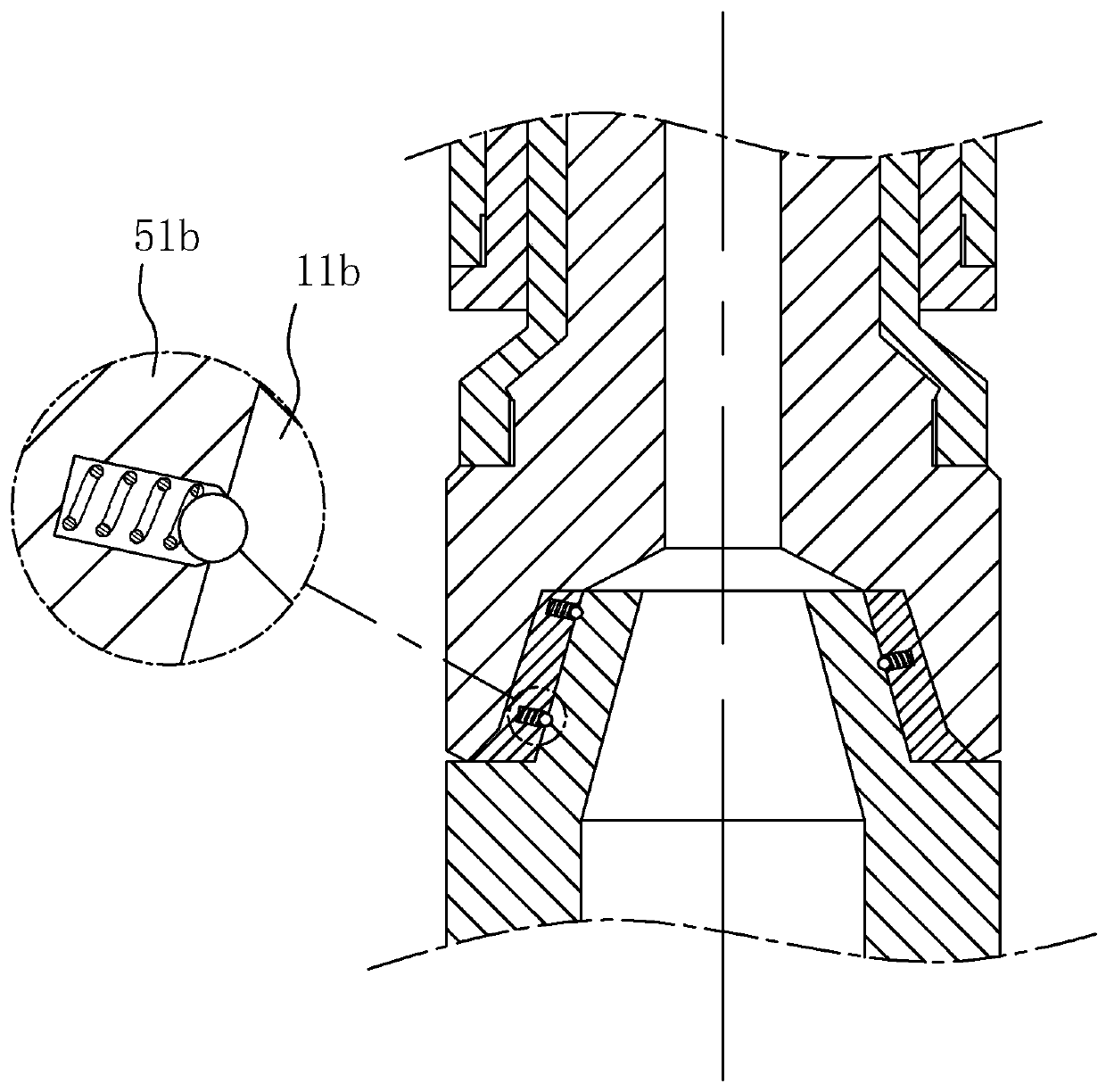

[0051] see figure 2 and image 3 One end of the transmission shaft 51a is provided with a fixing groove, the fixing groove is in the shape of a truncated cone and communicates with the hollow channel 511a, and the end facing the notch is a large end. A protective cover 51b is installed in the fixing groove, and the outer contour shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com