Intelligent following control system and intelligent following control method for cable of chain-driving coal cutter

A shearer and chain drive technology, applied in the field of the chain drive shearer cable intelligent follow-up control system, can solve the problems of reduced production efficiency, lost shearer signals, equipment downtime, etc., so as to improve production efficiency and reduce The number of production downtimes, the effect of easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

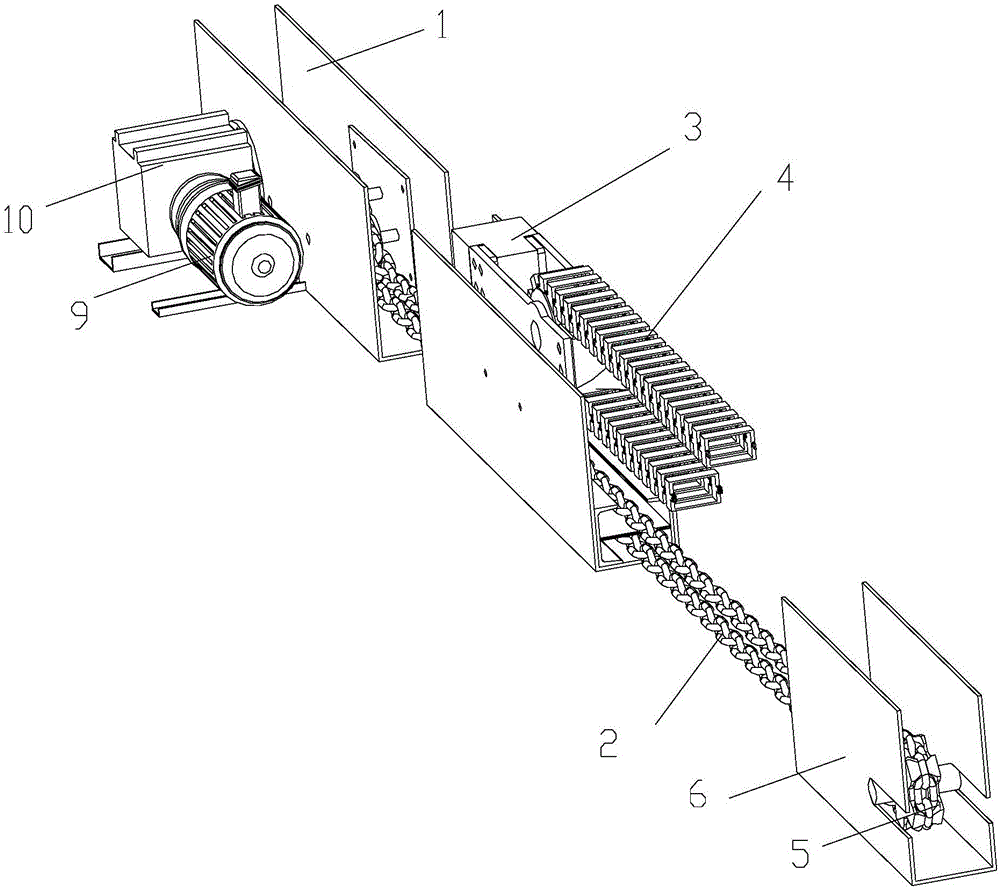

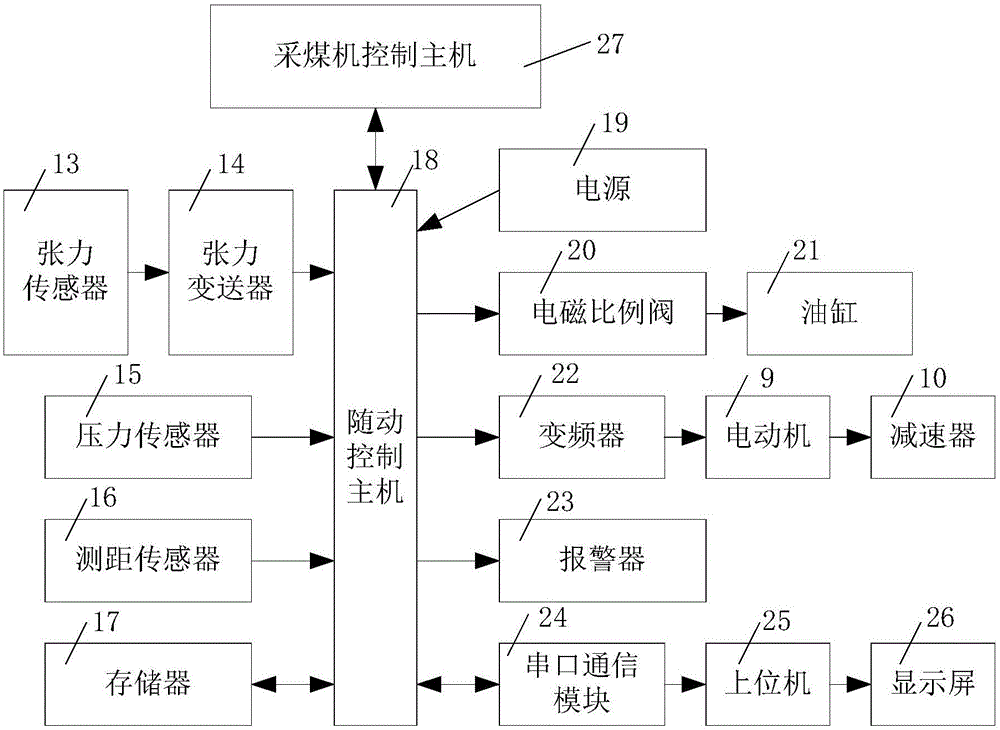

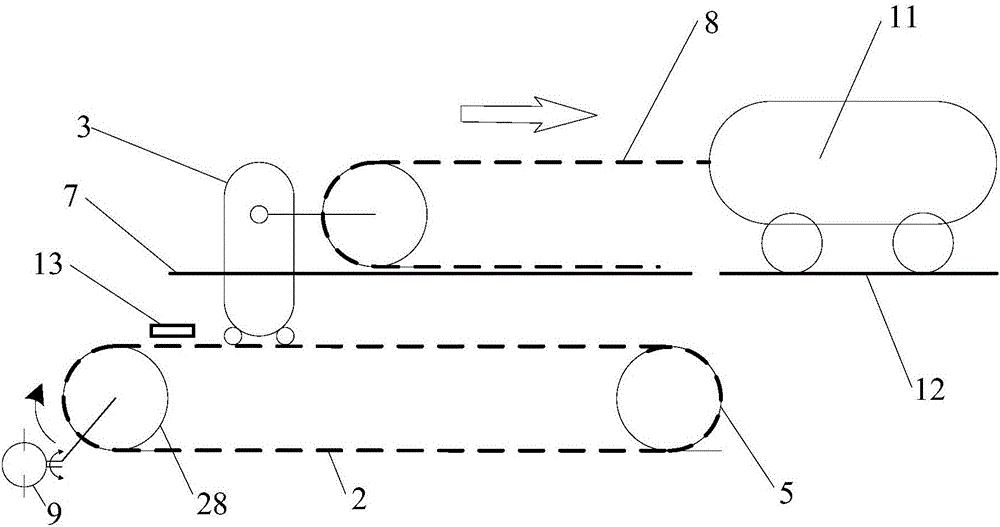

[0050] Such as figure 1 with figure 2 As shown, a chain-driven shearer cable intelligent follow-up control system according to the present invention includes a shearer control host 27 that communicates with the shearer 11 for controlling the operation of the shearer 11 and is used to control the cable dragging of the shearer. The follow-up control terminal for the operation of the device, the cable dragging device of the shearer includes a cable clamp 4 used to protect and drag the cable 8 of the shearer, and the cable clamp 4 is dragged by the chain 2 to move in the direction of movement of the shearer The sliding cable trolley 3, the motor 9 for driving the chain 2 motions and the reducer 10 connected with the output shaft of the motor 9, and the tail cable groove 1, the middle cable groove and the head cable groove 6, the reducer 10 The output shaft is connected with the driving sprocket 28 arranged in the tail cable groove 1, the driven sprocket 5 is arranged in the head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com