A steel pipe curtain structure support system and its construction method

A construction method and steel pipe technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as weak force at joints, achieve the effects of reducing construction cost, improving lateral stiffness and bearing capacity, and reducing settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

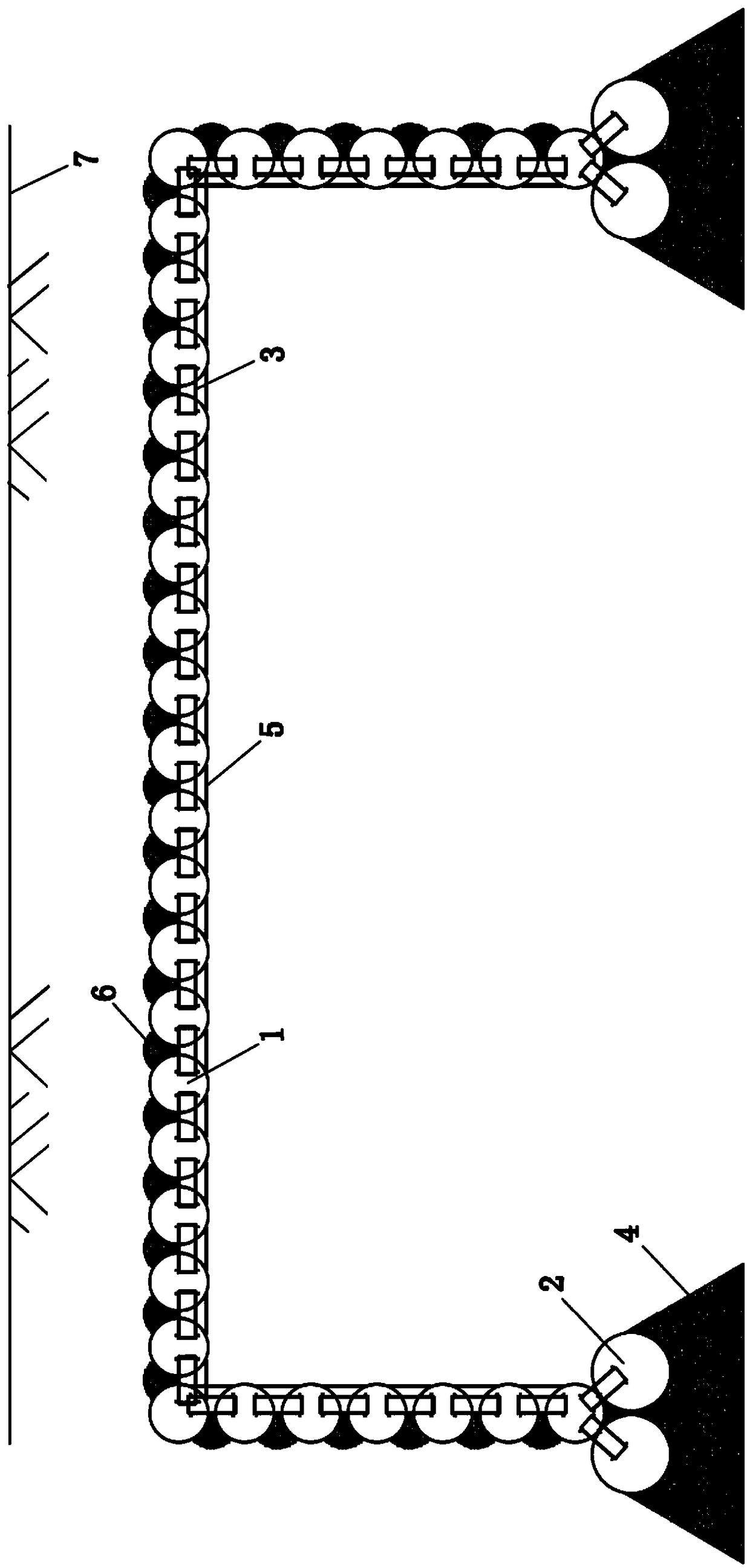

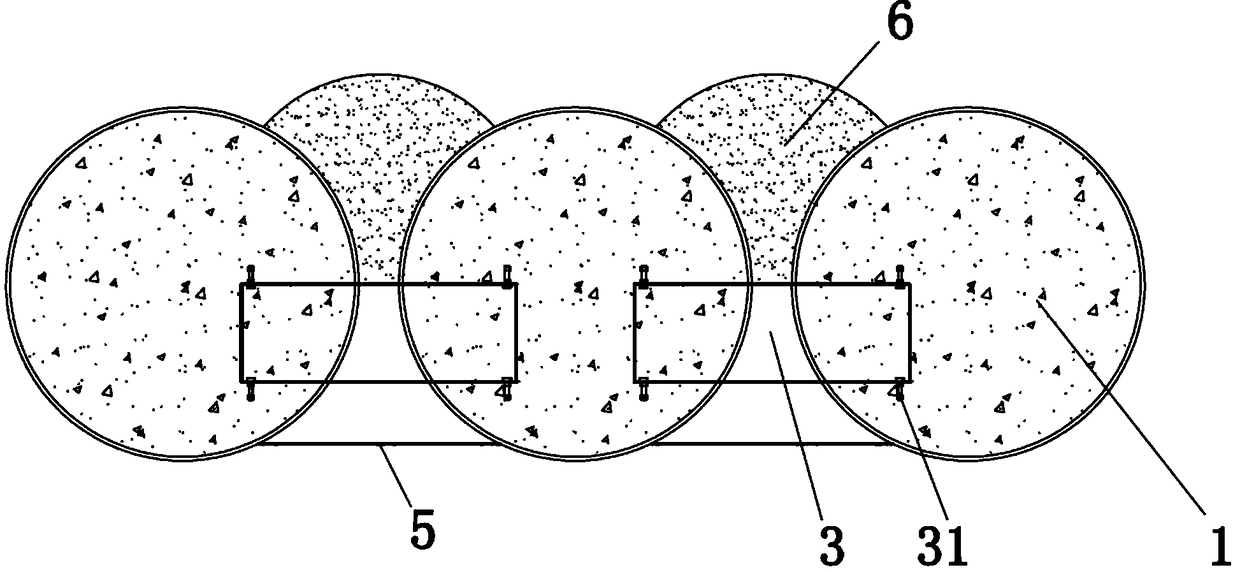

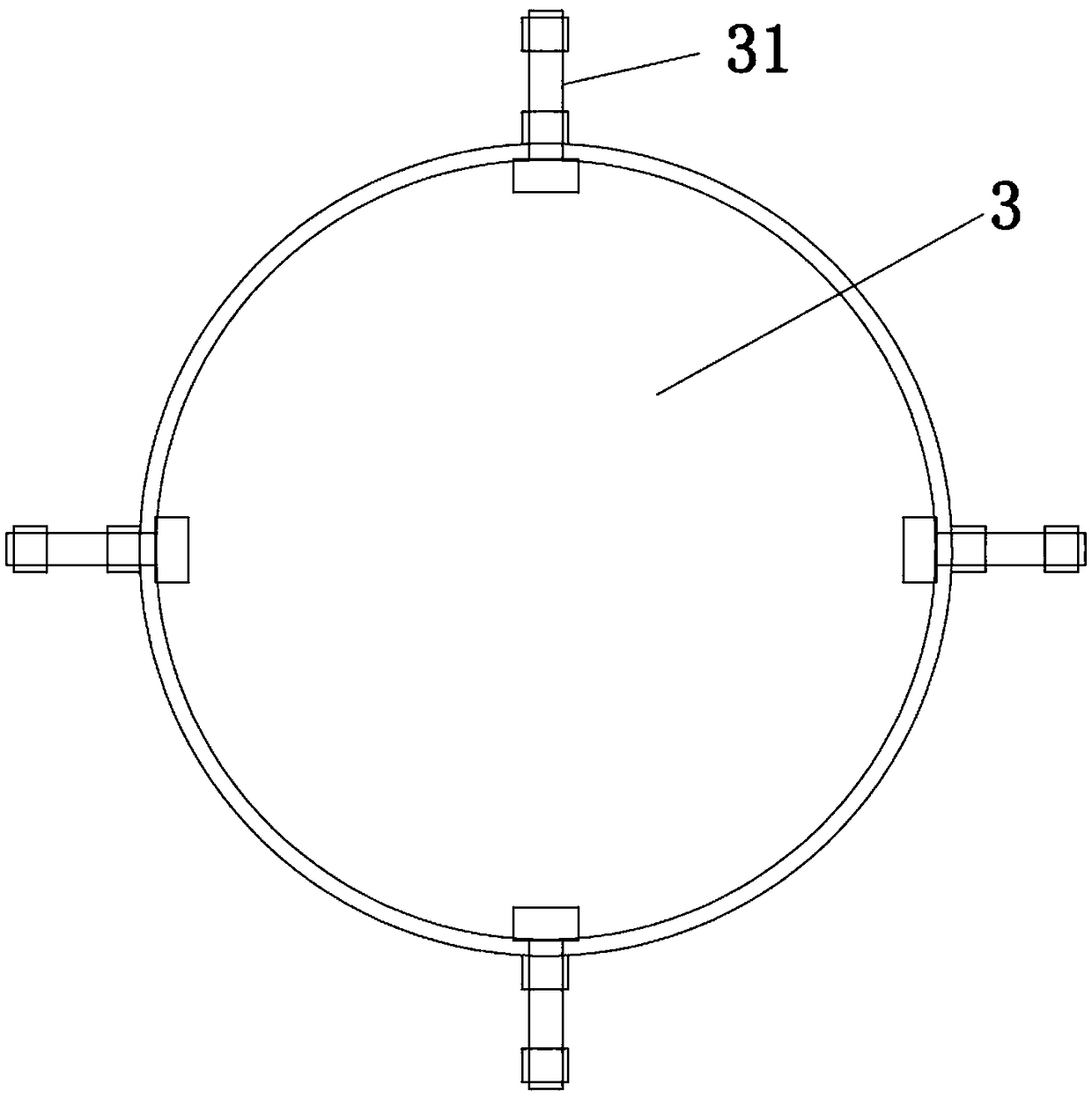

[0044] Such as Figure 1-5 As shown, Embodiment 1 of the present invention provides a steel pipe curtain structure support system, the pipe curtain structure includes a first steel pipe 1, a second steel pipe 2 and a third steel pipe 3, and the outer diameter of the second steel pipe 2 is larger than the first The outer diameter of the steel pipe 1 is large, there are multiple first steel pipes 1, second steel pipes 2 and third steel pipes 3, and the plurality of first steel pipes 1 are arranged in sequence to form an n-shaped structure. Connected by the third steel pipe 3, two second steel pipes 2 on the same horizontal plane are arranged at the two feet of the first steel pipe 1 forming an n-shaped structure, the first steel pipe 1, the second steel pipe 2 and the third steel pipe 3 poured with concrete;

[0045] The construction method of the steel pipe curtain structure support system comprises the following steps:

[0046] S1. Construction preparation: According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com