A construction method for building underground structures with large-diameter pipe jacking combined with hole piles

An underground structure and construction method technology, applied in underwater structures, infrastructure engineering, buildings, etc., can solve the problems of weak lateral stiffness between pipes, low space utilization rate, difficult construction in pipes, etc., to reduce land subsidence, improve Utilization rate, the effect of reducing the number of pipe jacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

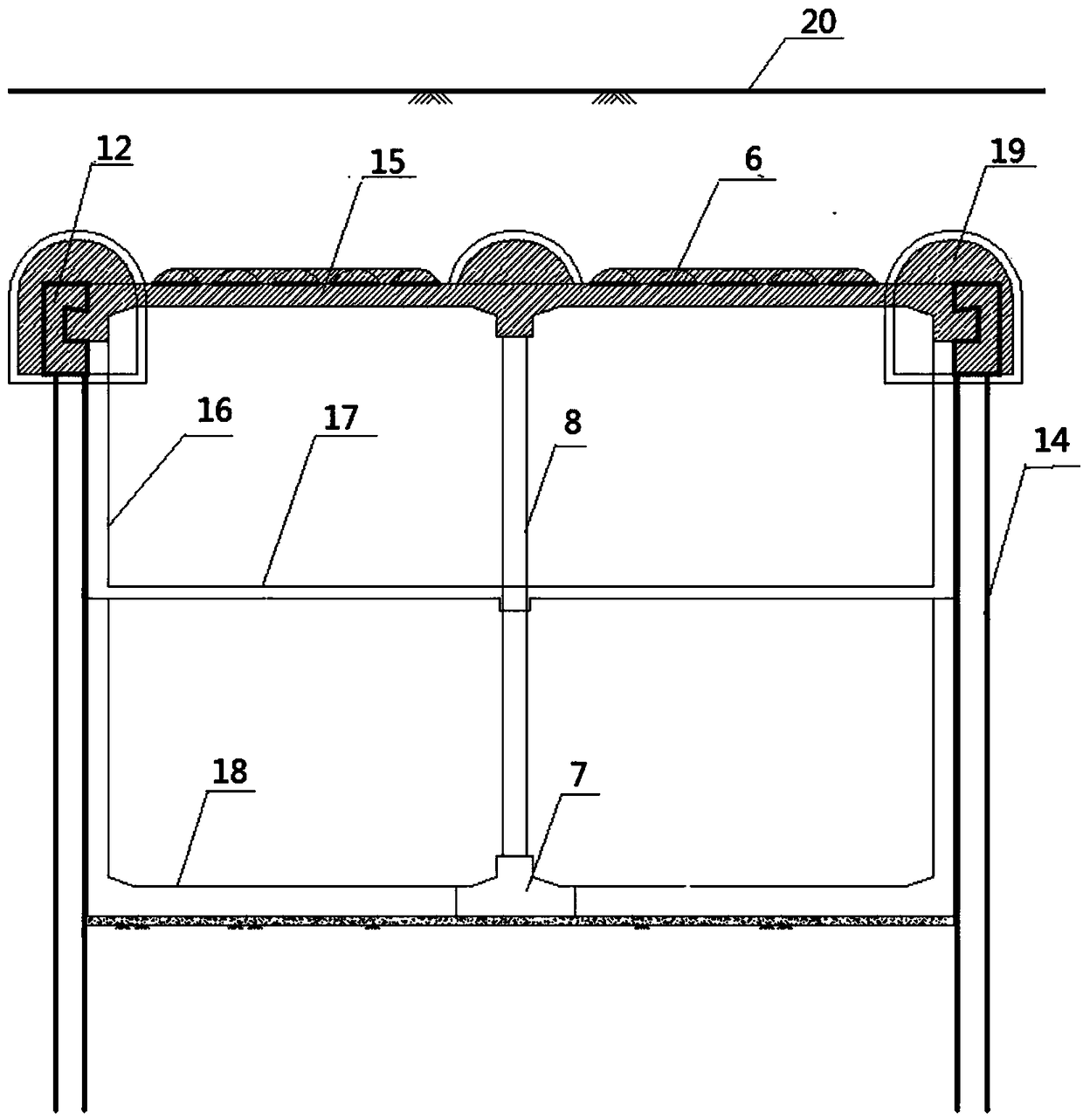

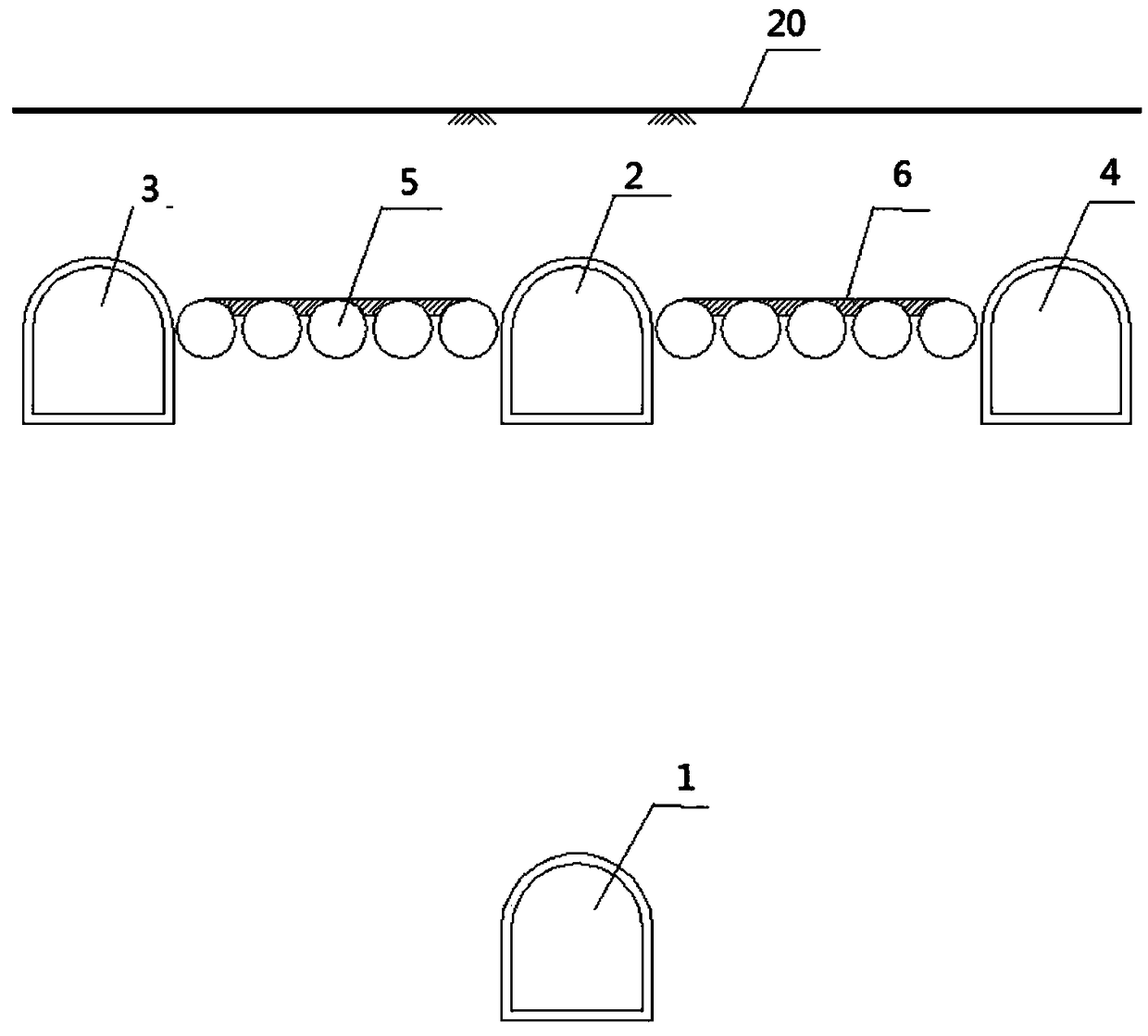

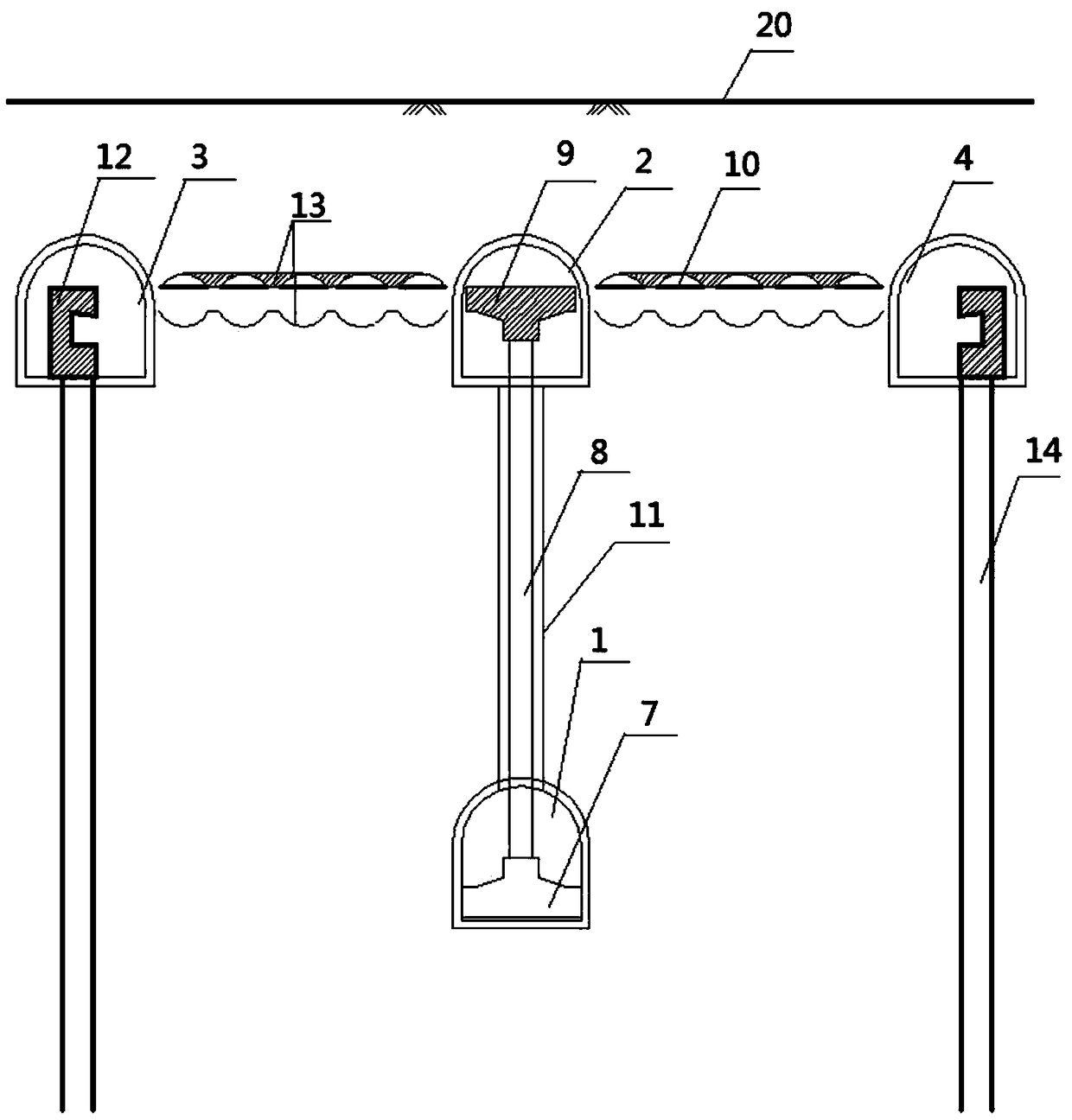

[0029] Such as Figure 1-Figure 3 Shown is a construction method for building an underground structure with large-diameter pipe jacking combined with hole piles, including the following steps:

[0030] (1) Use the open-cut work pit to construct the pilot tunnel under the ground according to the principle of first going down and then going up. During the construction of the pilot tunnel, the initial support should be done in time, and the soil body should be reinforced with grouting technology; the construction of pilot tunnel 1 should be carried out first , after the construction of pilot tunnel a, the construction of pilot tunnel b, pilot tunnel c, and pilot tunnel d will be carried out in sequence; pilot tunnel b is above pilot tunnel a, and pilot tunnel c and d pilot tunnel Both sides of hole 2;

[0031] (2) Using the foundation pit work surface excavated in the previous stage, the open-cut foundation pit on both sides of the construction work platform can be used as the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com