Stirling motor and defrosting unit

A technology of heating tubes and heat exchange components, which is applied to engine components, mechanical equipment, machines/engines, etc., can solve problems such as easy frosting and affect the working efficiency of Stirling motors, and achieve the effect of ensuring working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

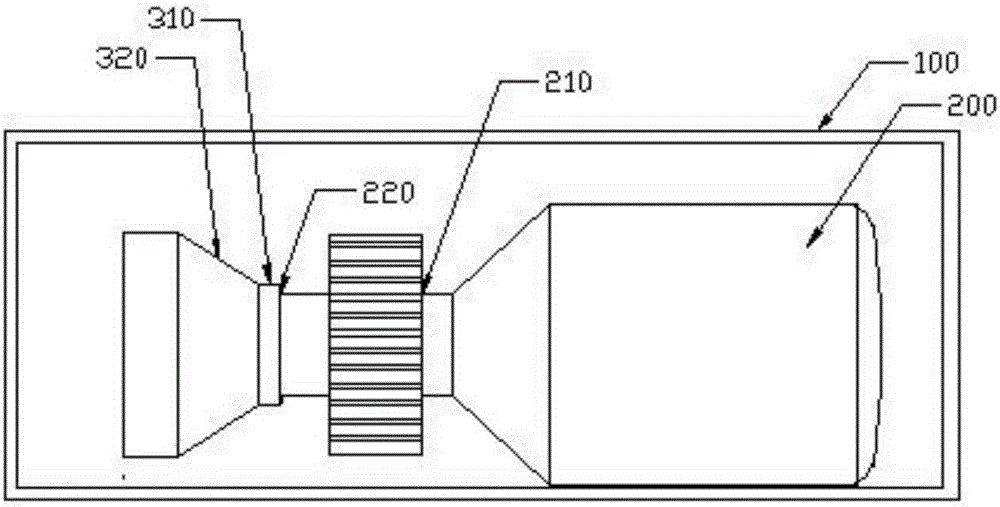

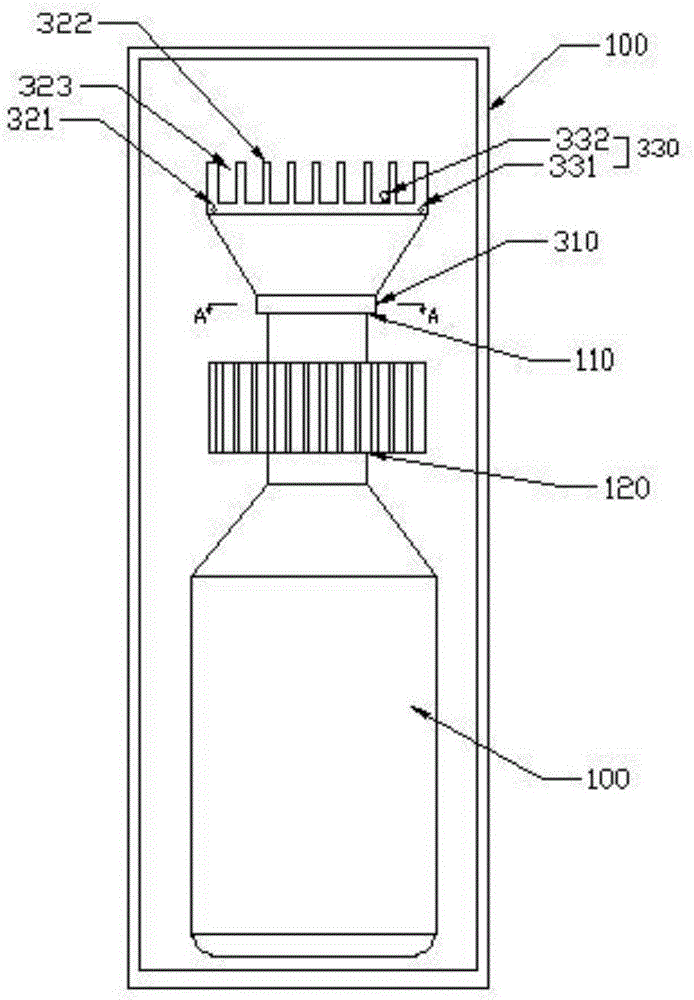

[0026] Embodiment 1, with reference to Figure 1-2 , a Stirling motor with a defrosting unit, including a housing 100 and a motor body 200, the motor body 200 includes a cold end 220 and a hot end 210, the cold end 220 is provided with a defrosting unit, and the defrosting unit includes a heat exchange Component 320, heating component 330 and fixed structure 310, the heat exchange component 320 is fixed to the cold end 220 through the fixed structure 310; the heating component 330 heats the heat exchange component 320 when working; the heating component 330 includes a heating tube 331, and the heat exchange component 320 On one side close to the fixing structure 310 , the shape of the embedding groove 321 is adapted to the heating pipe 331 , and the heating pipe 331 is embedded in the embedding groove 321 and arranged. There are two heating tubes 331, and the number of embedded grooves 321 corresponds to the number of heat exchange tubes. The arrangement direction of the heat...

Embodiment 2

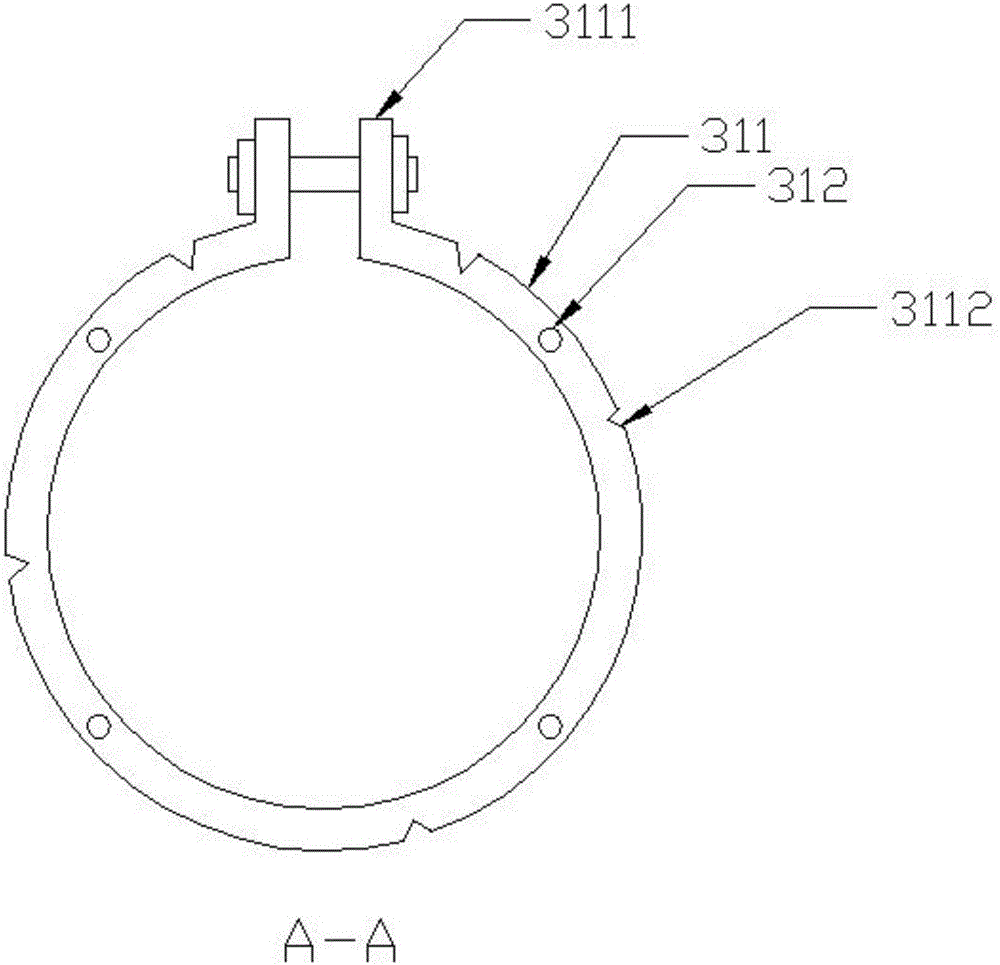

[0031] Embodiment 2, with reference to Figure 4As shown, the difference from Example 1 is that the heat exchange fins 322 and strip-shaped heat exchange protrusions in Example 2 are respectively arranged on both sides of the heat exchange plate 325, and the heat exchange fins 322 The length direction of the strip-shaped heat exchange protrusion is parallel to the length direction of the strip-shaped heat exchange protrusion; the embedded groove 321 is set on the strip-shaped heat exchange protrusion, and the number of the heating tubes 331 is set to two. 321 and the number of strip-shaped heat exchange protrusions. The number of the heating tubes 331 is correspondingly set to two, and there is a space between the two strip-shaped heating protrusions. The fixing structure 310 includes a round tube hoop 311, the round tube hoop 311 is fixed to the heat exchange plate 325, the round tube hoop 311 includes a fastening unit 3111, and the round tube hoop 311 fastens the cold end 22...

Embodiment 3

[0032] In Embodiment 3, the defrosting unit in Embodiment 1 is used alone, and the defrosting unit can be fixed on any Stirling motor through the fixing structure 330 to realize the defrosting work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com