Multi-structure pump

A multi-structure, pump body technology, applied in the direction of pumps, pump components, non-variable capacity pumps, etc., can solve the problems of vacuum pumping, water inlet pipeline irrigation, etc., to improve production efficiency, high versatility, and avoid rust stuck. dead and unable to work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

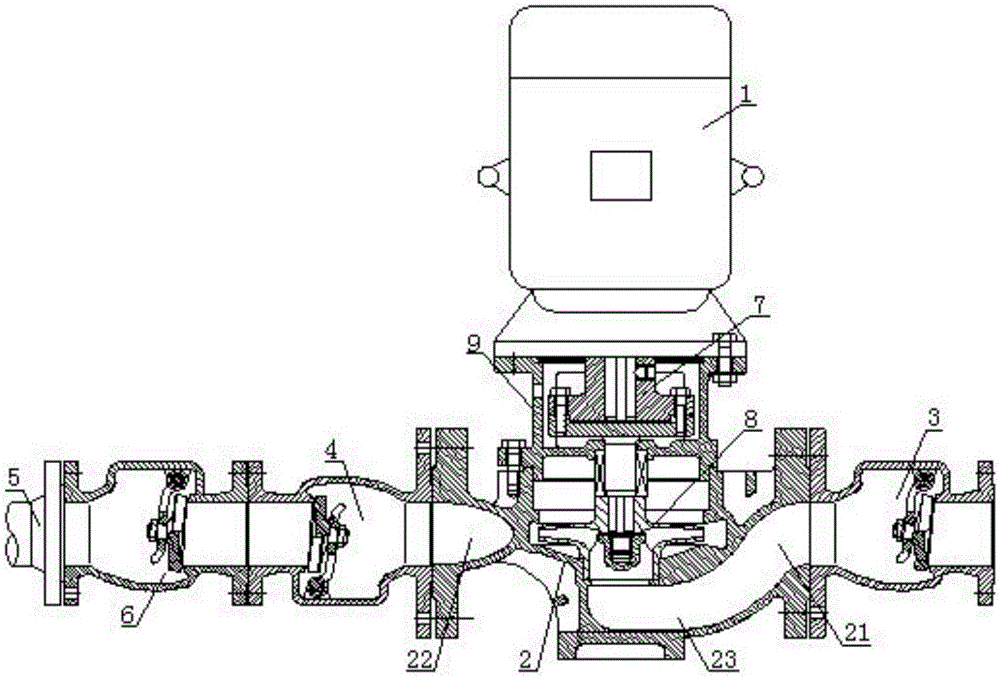

[0031] A multi-structure pump, comprising a motor 1 and a pump body 2, the pump body 2 includes a water inlet 21, a water outlet 22, and a water inlet channel 23; the water inlet 21 and the water outlet 22 are arranged on the same horizontal plane, and the water inlet 21 The position is higher than the height of the water inlet channel 23, and the motor 1 is arranged vertically; the water inlet 21 is connected with the first check valve 3 for preventing the remaining water in the water inlet channel 23 from flowing away from the water inlet 21 after the pump is stopped; The water port 22 is connected with a second check valve 4 for avoiding the loss of residual water in the water outlet 22 after the pump is stopped, and the other end of the second check valve 4 is provided with a water outlet pipeline 5 .

[0032] The water inlet 21 and the water outlet 22 of the pump body 2 of the present invention are arranged on the same horizontal plane, which is convenient for installation...

Embodiment 2

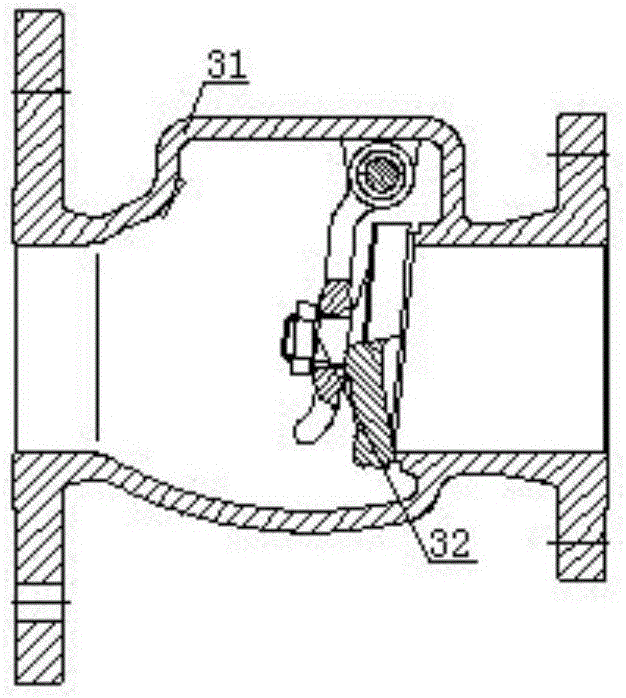

[0034] A multi-structure pump, comprising a motor 1 and a pump body 2, the pump body 2 includes a water inlet 21, a water outlet 22, and a water inlet channel 23; the water inlet 21 and the water outlet 22 are arranged on the same horizontal plane, and the water inlet 21 The position is higher than the height of the water inlet channel 23, and the motor 1 is arranged vertically; the water inlet 21 is connected with the first check valve 3 for preventing the remaining water in the water inlet channel 23 from flowing away from the water inlet 21 after the pump is stopped; The water port 22 is connected with a second check valve 4 for avoiding the loss of residual water in the water outlet 22 after the pump is stopped, and the other end of the second check valve 4 is provided with a water outlet pipeline 5 . The water inlet 21 and the water outlet 22 of the pump body 2 of the present invention are arranged on the same horizontal plane, which is convenient for installation and has ...

Embodiment 3

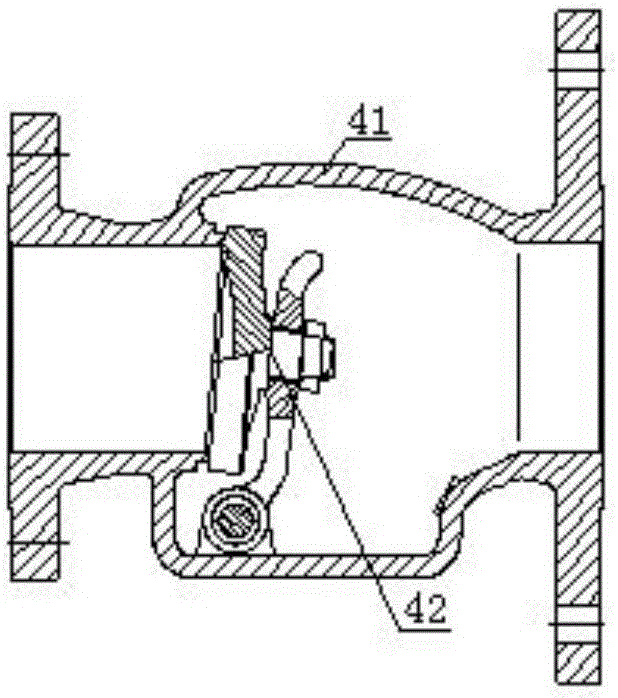

[0037] A multi-structure pump, comprising a motor 1 and a pump body 2, the pump body 2 includes a water inlet 21, a water outlet 22, and a water inlet channel 23; the water inlet 21 and the water outlet 22 are arranged on the same horizontal plane, and the water inlet 21 The position is higher than the height of the water inlet channel 23, and the motor 1 is arranged vertically; the water inlet 21 is connected with the first check valve 3 for preventing the remaining water in the water inlet channel 23 from flowing away from the water inlet 21 after the pump is stopped; The water port 22 is connected with a second check valve 4 for avoiding the loss of residual water in the water outlet 22 after the pump is stopped, and the other end of the second check valve 4 is provided with a water outlet pipeline 5 . The water inlet 21 and the water outlet 22 of the pump body 2 of the present invention are arranged on the same horizontal plane, which is convenient for installation and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com