Spiral separation device for hydraulic oil tank breather

A technology of screw separation and hydraulic oil tank, which is applied in the direction of oil supply tank device, fluid pressure actuating device, fluid pressure actuating system components, etc. area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

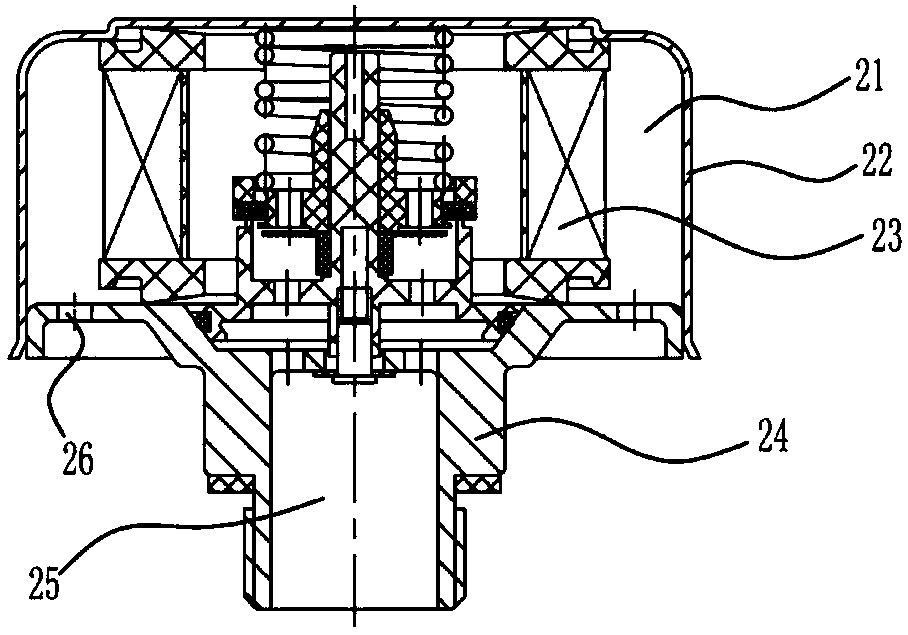

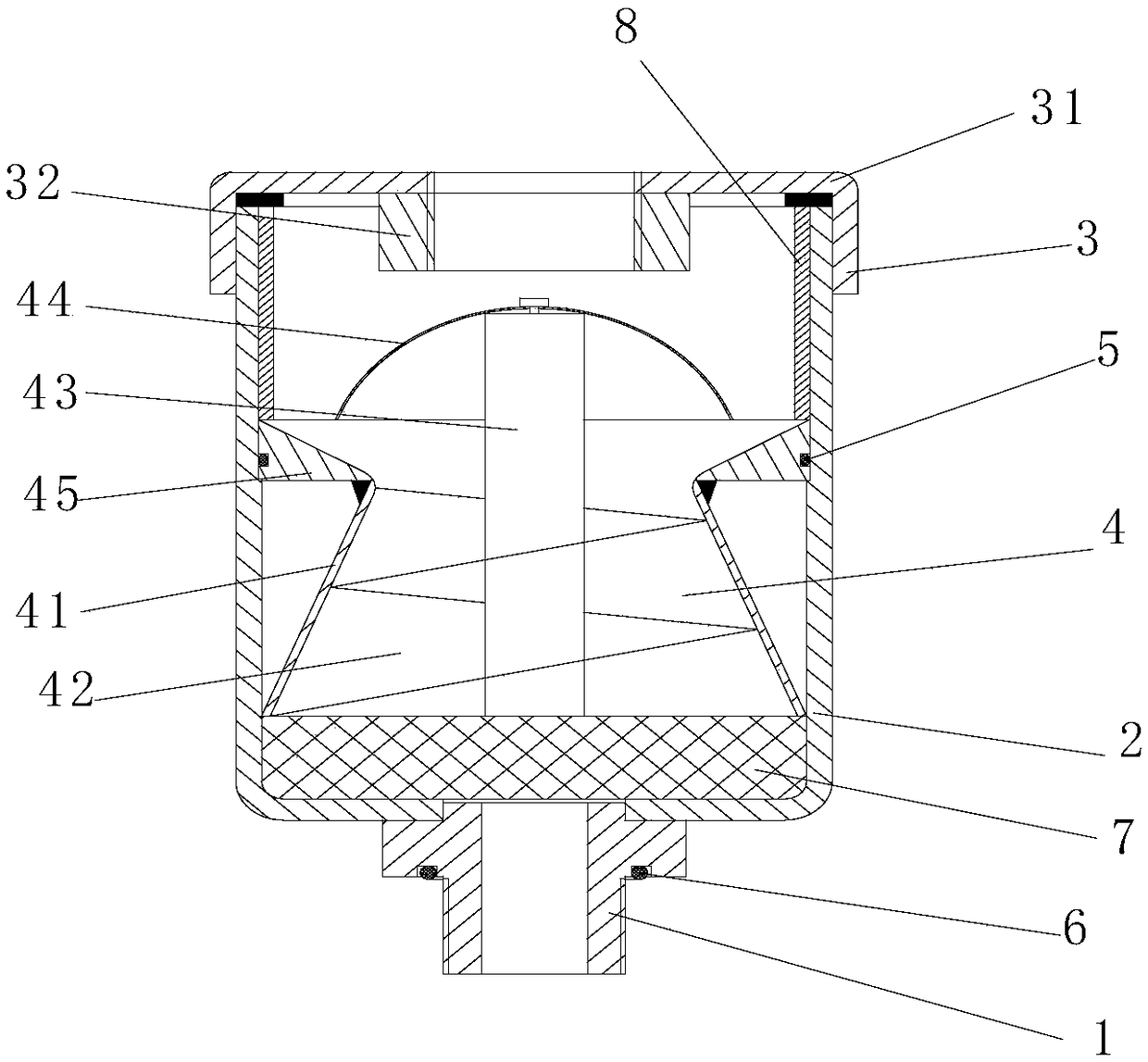

[0026] Such as Figure 1-2 As shown, the spiral separation device for the hydraulic oil tank breather includes a connecting seat 1 for connecting the oil tank, a housing 2 arranged on the connecting seat 1 and a cover 3 arranged on the housing 2, and the connecting seat 1 is provided with a vent hole The cover 2 is provided with threaded holes for connecting the respirator, and also includes a spiral separation part 4 arranged between the housing 2 and the cover 3. The spiral separation part 4 includes a separation cylinder 41, a spiral blade 42, a blade shaft 43 and Partition baffle 44, spiral blade 42 outer edge is fixed on the inner wall of separation cylinder 41, and inner edge is fixed on the blade shaft 43, and the lower end of blade shaft 43 is flush with the lower end of separation cylinder 41, and the upper end stretches out separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com