Two-grade buffering and stopping mechanism of free piston

A buffer structure and piston technology, applied in mechanical equipment, springs, shock absorbers, etc., can solve the problems of large impact load of equipment, easy damage of elastic buffer pads, limited absorption of piston kinetic energy by buffer pads, etc. The effect of the rebound of the small piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The accompanying drawing discloses a schematic structural view of a preferred embodiment of the present invention without limitation, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

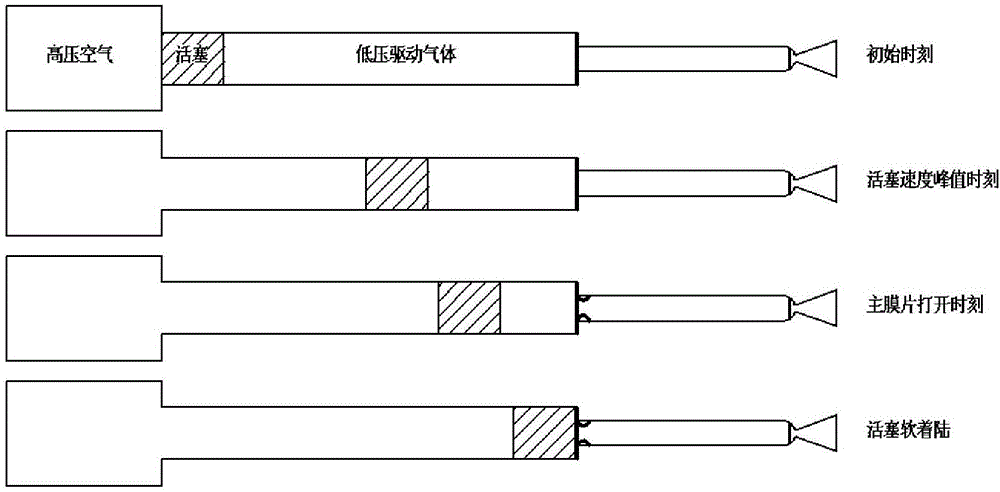

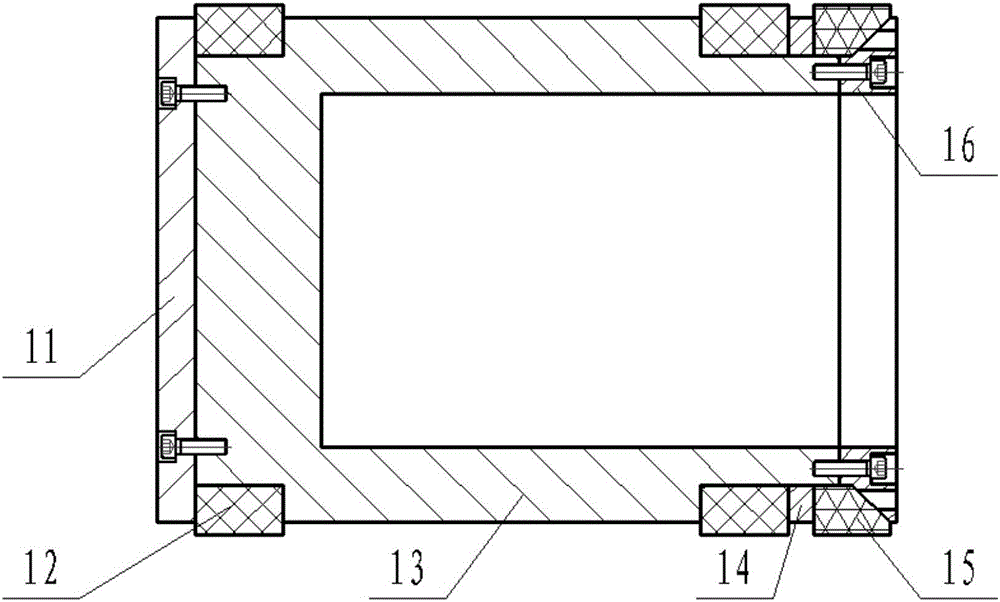

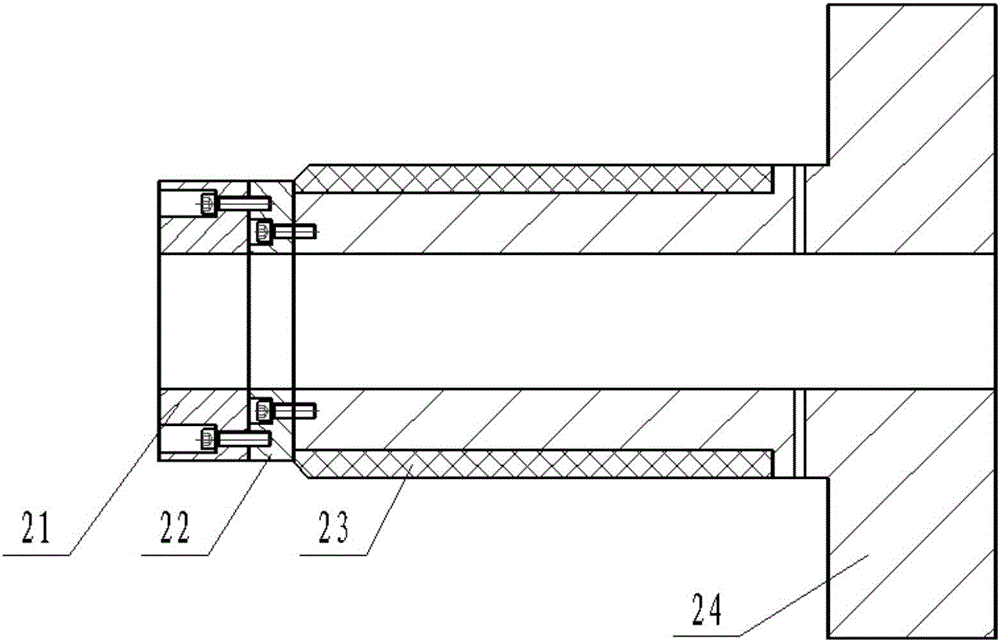

[0028] A free piston and pneumatic buffer stop mechanism design, such as figure 2 , 5 As shown, the free piston 1 is a cavity structure, including a rear end cover 11, a wear ring 12, a piston body 13, a retaining ring 14, a sealing ring 15 and a front end cover 16; the rear end cover 11 is fixed on the piston body by screws, The wear-resistant ring 12 is set on the piston body 13. The outer diameter of the wear-resistant ring 12 is larger than the outer diameter of the piston body. The seal ring 15 is set on the piston body. 45° included angle), the front end cover 16 is fixed on the piston body by screws, and the front end cover 16 has 12 vent holes with a diameter of 12mm, and the vent holes act on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com