Adjustable pipe exhaust device

An exhaust device and adjustable technology, applied in valve devices, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of high suction, increase enterprise expenditure, pollution, etc., achieve long service life, increase concentration, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

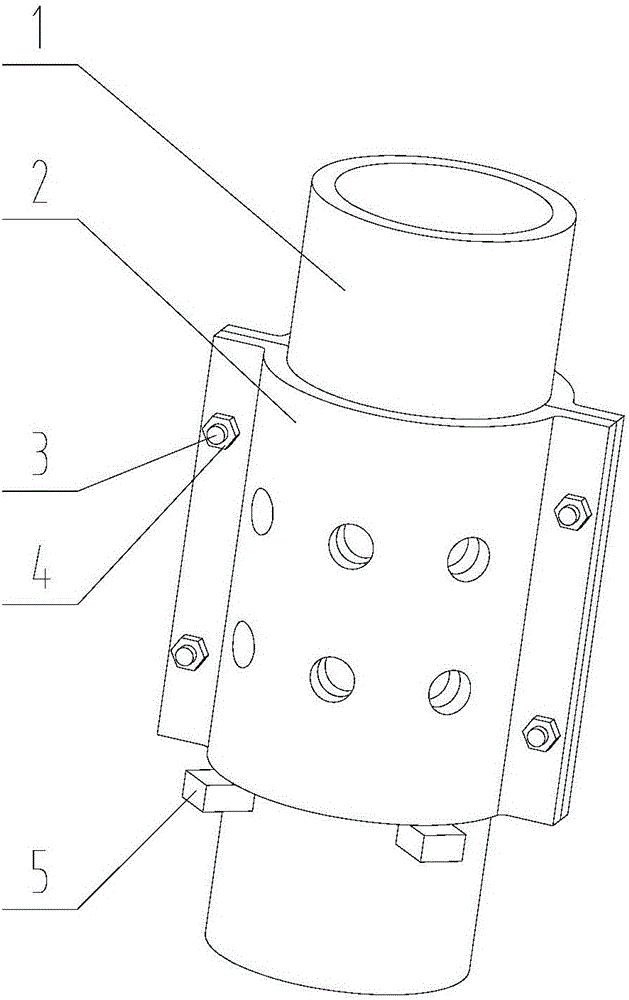

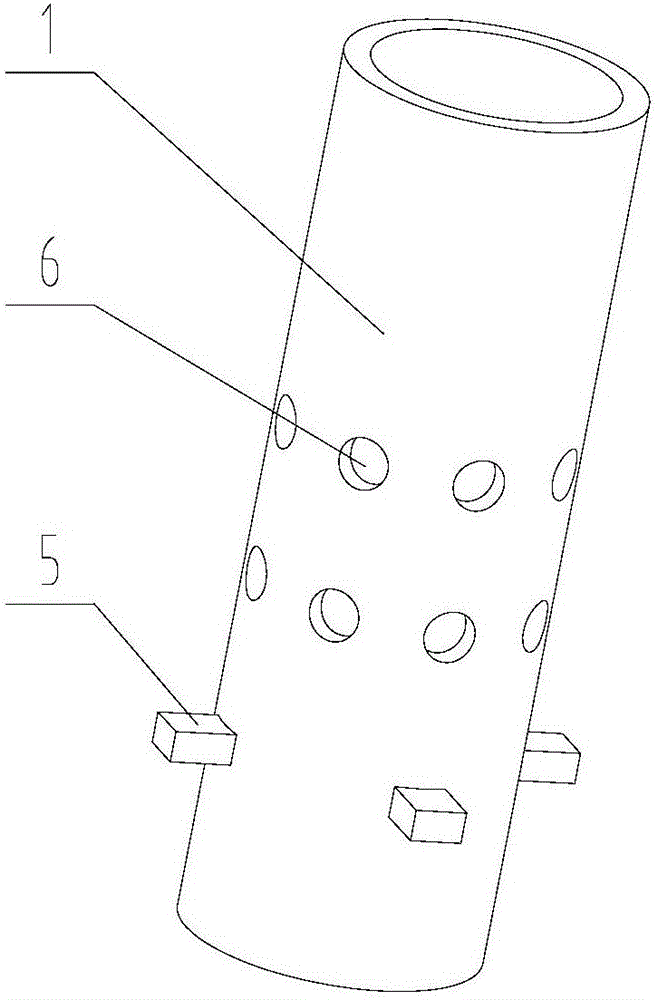

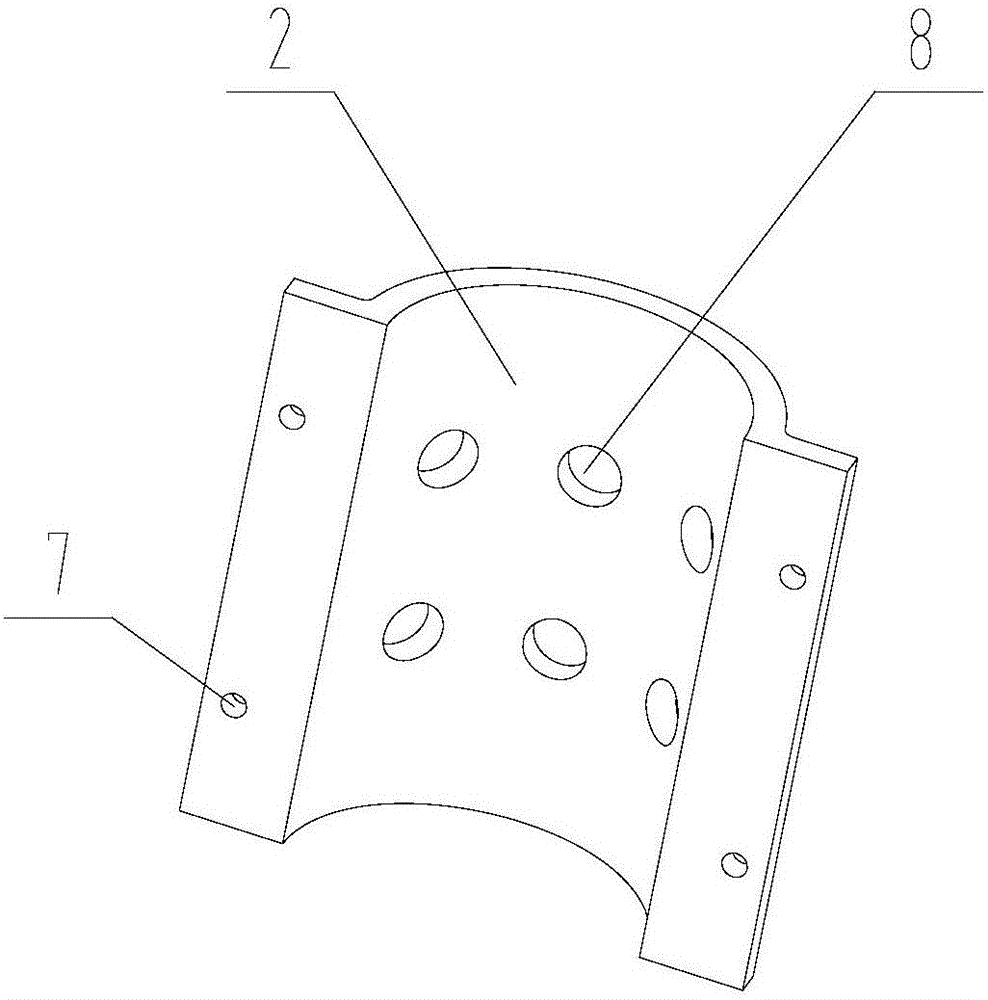

[0018] Such as Figure 1~3 As shown, an adjustable pipeline exhaust device includes an exhaust branch pipe 1, a clamp 2 and a support plate 5, wherein, the circumferential wall of the exhaust branch pipe 1 with a cylindrical cylindrical structure is provided with several pipe rows. Air holes 6, for example, can distribute several rows in the axial direction along the cylinder wall of the exhaust branch pipe 1, and evenly distribute several pipeline exhaust holes 6 along the circumferential direction; There are several support plates 5 fixed on it; the clamp 2 is two symmetrical semi-circular cylinder structures, which include a central arc-shaped surface matching the outer wall of the exhaust branch pipe 1, and an extension surface of the arc-shaped surface, and are in There is a clamp bolt hole 7 on the extension surface, and a clam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap