Drain plug, drainage system and refrigerator

A technology for plugs and drainage pipes, which is applied to household refrigeration equipment, lighting and heating equipment, defrosting, etc., can solve the problems of error-prone, sticking, high cost of molds and components made of silicone materials, and reduce production costs. Simple structure and the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

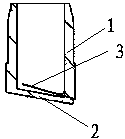

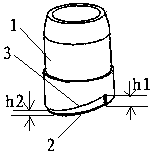

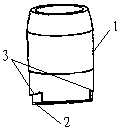

[0025] Such as figure 1 As shown, the drainage plug proposed by the present application includes a plug body 1, and the plug body is hollow tubular; one end of the plug body is open for connecting the drainage pipeline; the other end of the plug body is closed, and the sealing surface 2 is opposite The plug body is inclined; along the inclined bottom a of the closed surface 2 to the inclined top b direction of the closed surface, there is a cutting line 3 separating the closed surface 2 and the plug body 1, so that the closed surface 2 and the plug body 1 are half separated state.

[0026] When the drainage plug is used in the drainage system, the drainage plug is installed vertically at the end of the row of pipelines, and the semi-separated and inclined sealing surface 2 is separated from the plug body 1 when there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com