Strip online cleaning equipment

A technology for cleaning equipment and strips, applied to lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as general effect, impossibility, and large loss, and achieve thorough and efficient cleaning, structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

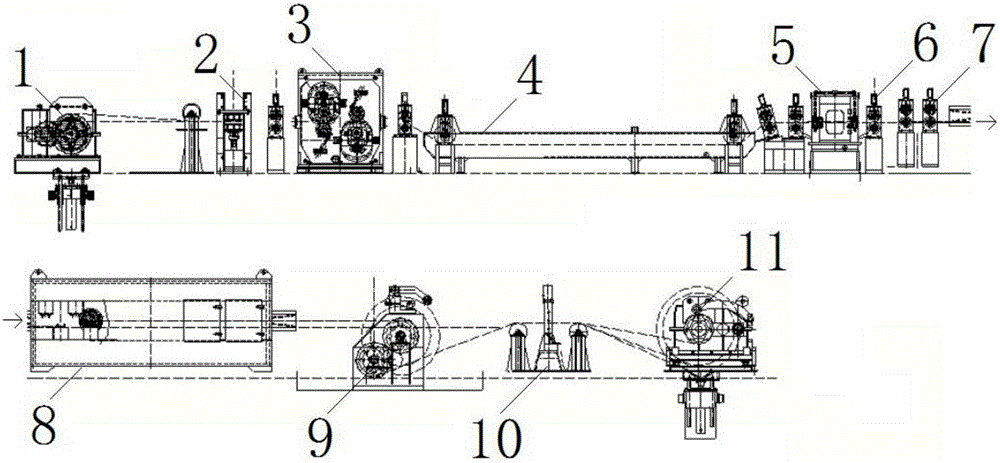

[0022] like figure 1 As shown, the strip online cleaning equipment includes an uncoiler 1, a process auxiliary mechanism 2, a pretreatment brush roller mechanism 3, an ultrasonic comprehensive cleaning tank 4, a spray rinsing mechanism 5, a squeeze roller 6, and an auxiliary pinch Mechanism 7, Suspension Drying Mechanism 8, Constant Tension Mechanism 9, Automatic Centering Mechanism 10, Winding Machine 11, the setting sequence is according to the production and running direction to form an ultrasonic comprehensive online cleaning equipment, and the pretreatment brush roller mechanism removes large Volumetric attachments, the residue on the strip is cleaned by the vibration of the ultrasonic comprehensive cleaning tank, which is equivalent to a sauna cleaning to remove the residue, even the dirt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com