Circular paper pressing-in device for combined fireworks

A combination of fireworks and press-in device technology, applied in the direction of pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of low production efficiency, heavy labor load, uneven product quality, etc., to achieve reliable work, high work efficiency, and work glitch-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

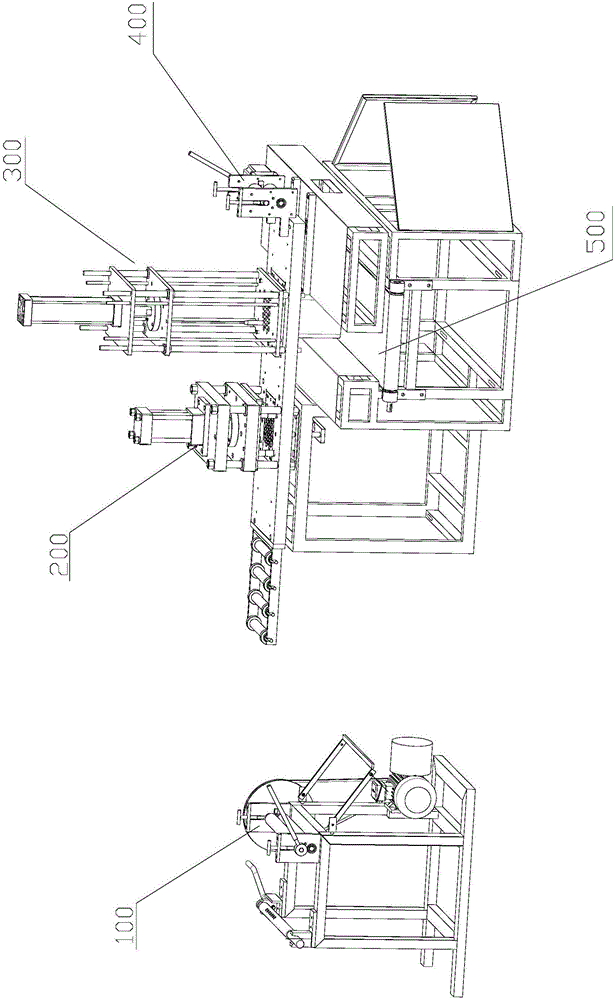

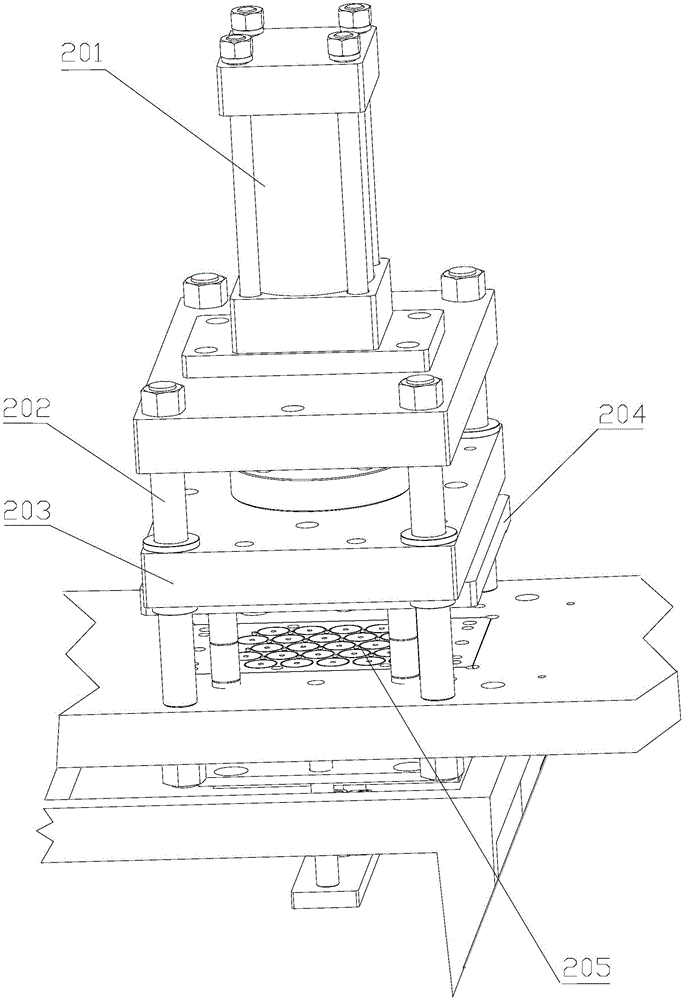

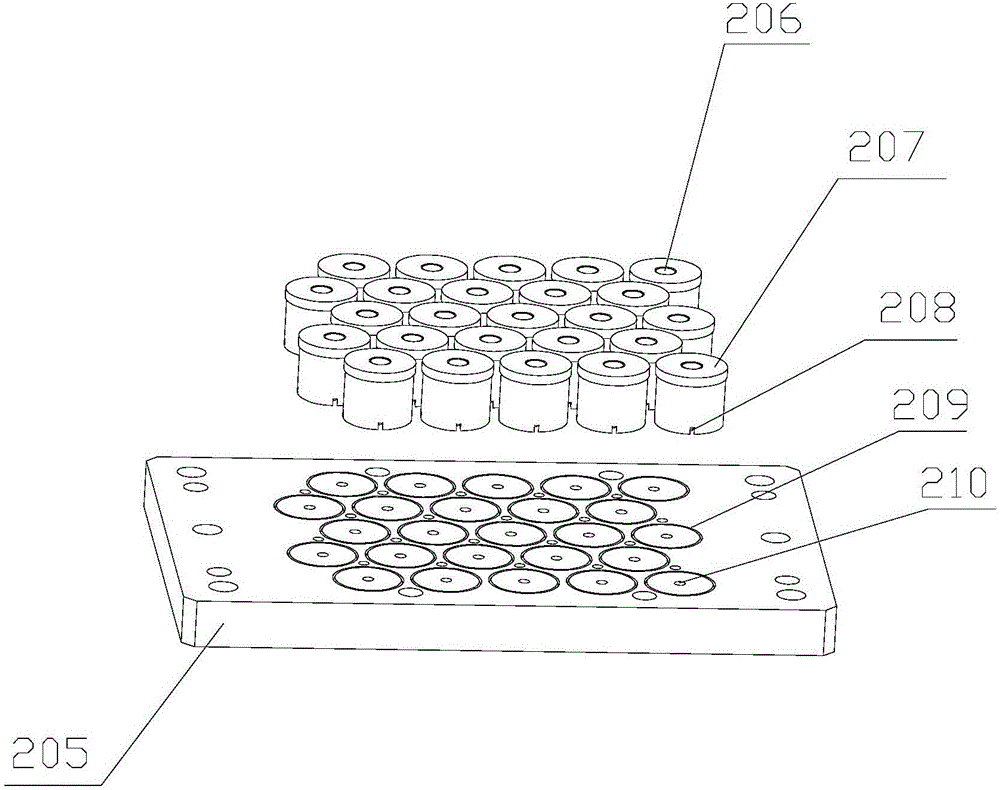

[0026] Embodiment 1: see attached Figure 1-7 , reflecting a specific structure of the present invention, the paper-reeling device of the combined fireworks includes a paper unwinding mechanism 100 and a paper reel mechanism 400 that are arranged to cooperate with each other, and the paper unwinding mechanism 100 and the paper reel mechanism 400 Acting according to the control system instruction, the paper roll mechanism 100 is a paper roll provided with a rotating shaft, and releases complete yellow cardboard. The paper take-up mechanism 400 is a paper reel shaft connected to a driving motor. The paper reel shaft rotates at a certain angle each time it moves, driving a proper amount of paper forward. The reel mechanism pulls the stamped paper remains, and drives the paper to pass through the paper stamping mechanism 200 and the paper stamping mechanism 300 in order to form continuous paper supply.

[0027] Between the unwinding roll mechanism 100 and the paper take-up roll m...

Embodiment 2

[0031] Embodiment 2: The difference from Embodiment 1 is that a secondary buffer mechanism is provided. Such as Figure 8As shown, the buffer mechanism 800 of the needle bar and the press-in buffer mechanism 600 constitute a secondary buffer mechanism, and the structure of the buffer mechanism 800 of the needle bar is the same as that of Embodiment 1 and will not be repeated here.

[0032] The connecting rod 700 of the press-in punch is provided with a press-in buffer mechanism, please combine Figure 9 , the connecting rod 700 is divided into an upper connecting rod 701 and a lower connecting rod 702, the upper connecting rod 701 is fixedly connected to the outer casing 602, the inner cavity of the outer casing 602 is set with a punch spring 603 and a piston 604, and the lower end of the piston 604 is fixed to the lower connecting rod 702, and the piston 604 Pin rods 605 are arranged on both sides, and sliding grooves 606 are arranged on both sides of the jacket 602 , and th...

Embodiment 3

[0033] Embodiment 3: see Figure 10 , 11 , the difference from Embodiment 1 is that the needle bar 501 near the needle point 503 is provided with an elastic clip 502 protruding from the side opening of the needle bar 501 . During the process of inserting / exiting the central hole of the paper, the elastic clip 502 is compressed and deformed, and recovers after passing through the central hole. The paper sticks cannot fall off; when the needle bar 501 is pulled out from the center hole, the paper sticks will not follow the needle bar 501 to go up in close contact with the tube wall, but will stay in the fireworks tube. At the same time, when the elastic clip 502 passes through the center hole, The tilted paper has a leveling and correcting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com