An inner tube placement device for combined fireworks

A technology for combining fireworks and placing devices, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as difficulty in putting in the inner cylinder, damage to the outer cylinder, and difficult specifications of the outer cylinder, achieving simple mechanism, reliable operation, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

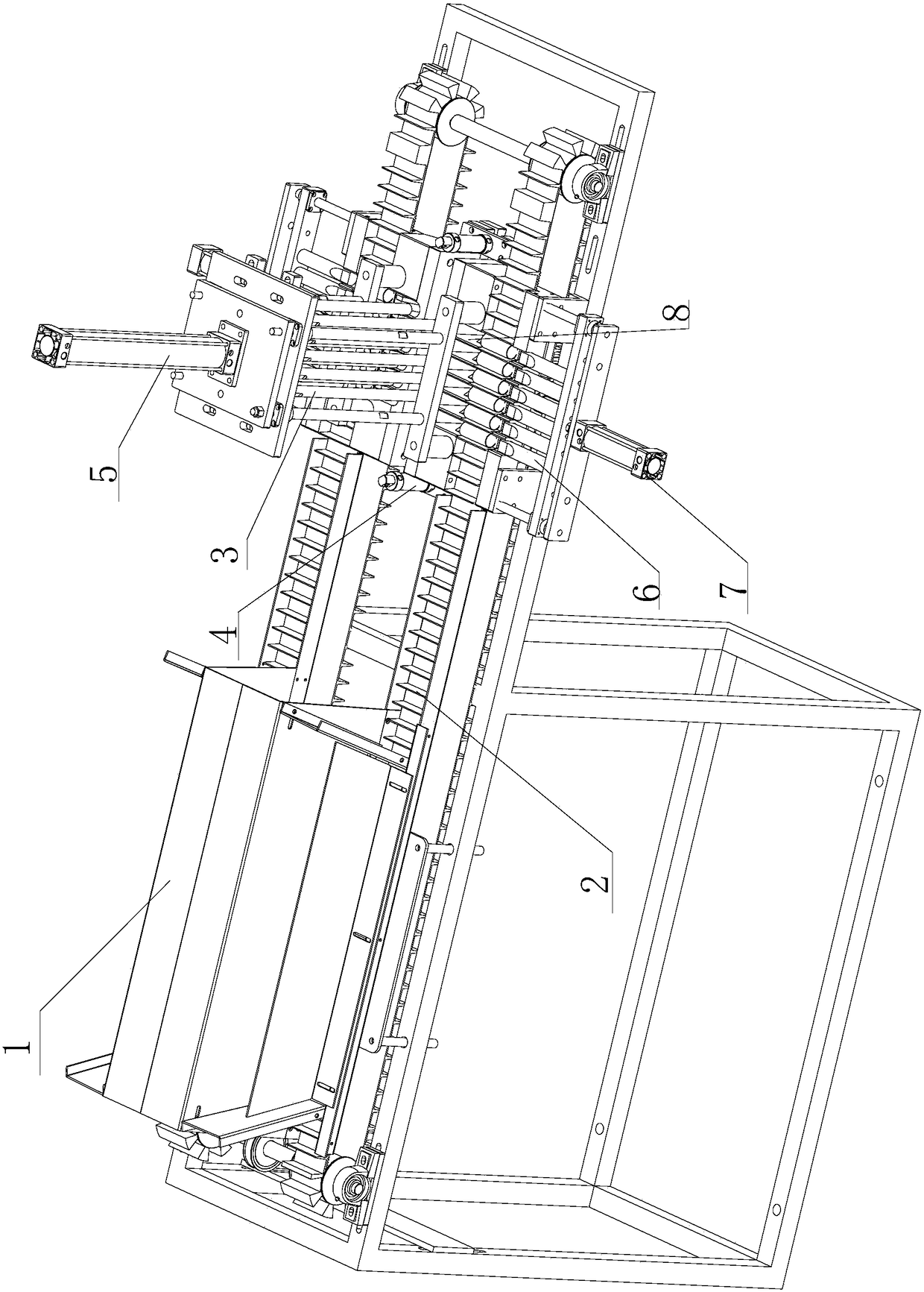

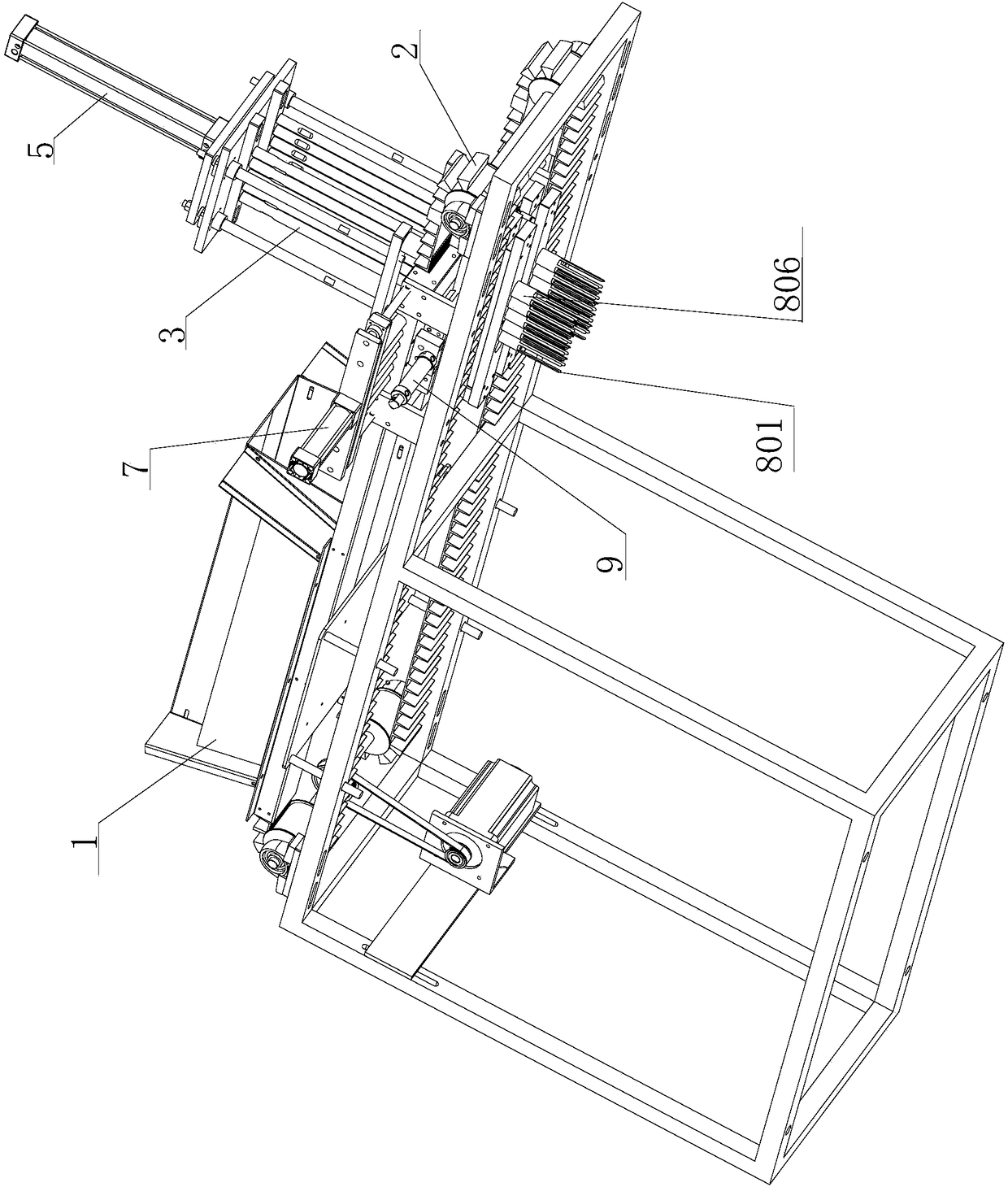

[0017] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the inner barrel placement device of the combined fireworks includes a lower pressure rod 3 connected to the first reciprocating drive cylinder 5 to move up and down, and also includes a barrel-entry guide and a variable guide The guiding assembly 8 that guide piece constitutes.

[0018] In this example, six guide assemblies 8 are arranged side by side to form the first working group, and the other six guide assemblies 8 form the second working group. The grid conveyor belt 2 and the two groups of pressing rods 3 share a first reciprocating drive cylinder 5 . Each working group processes six fireworks outer cylinders at a time, that is, to pack six inner cylinders into six outer cylinders respectively.

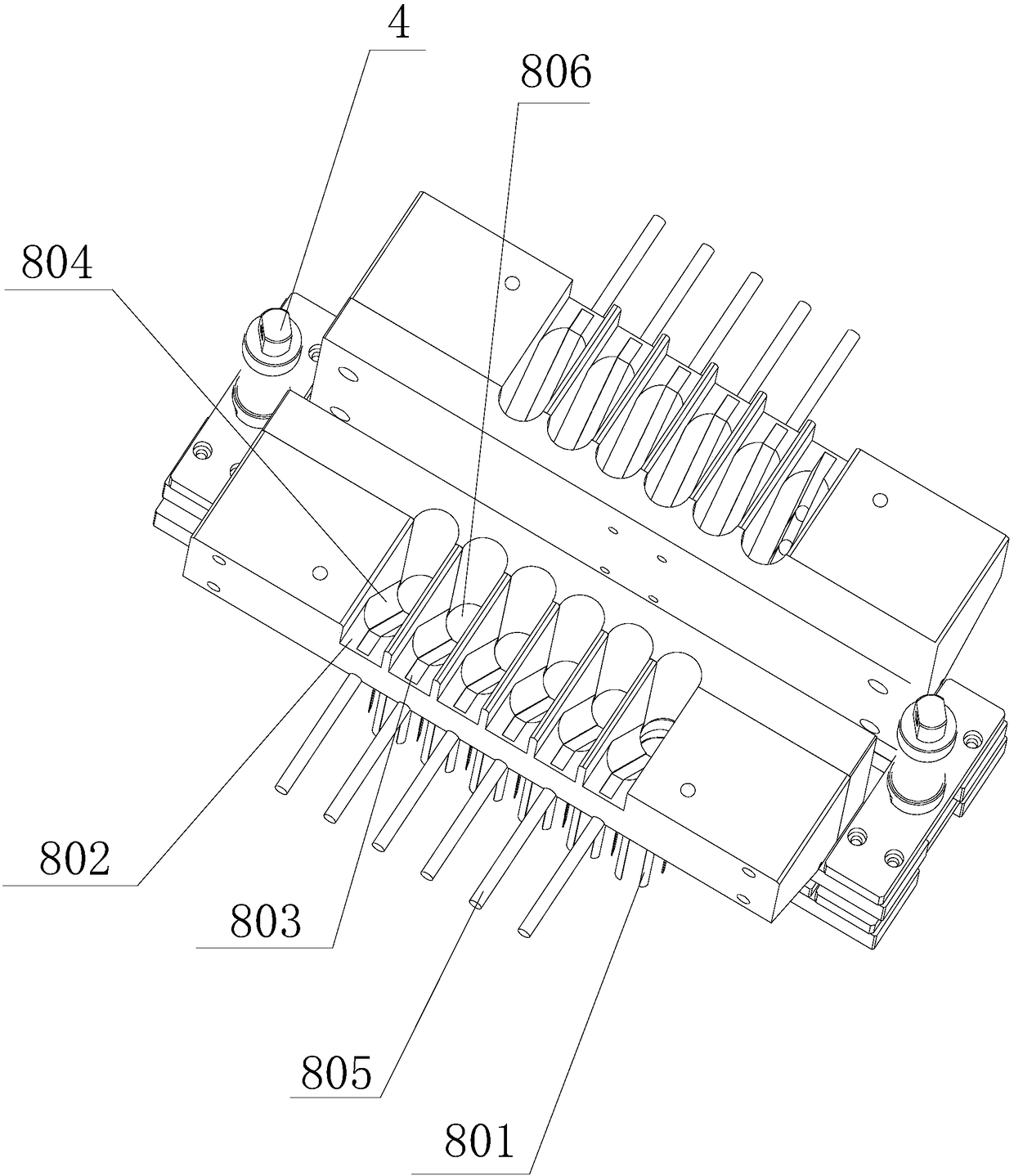

[0019] In each bootstrap component 8:

[0020] The tube-in guide includes an upper and lower channel 806 that only allows a single inner tube to pass through in the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com