Supercharger shell detection system and method

A supercharger housing and inspection system technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of large random errors, affecting the quality and productivity of supercharger finished products, low efficiency, etc., and achieve good processing quality , Improving the inspection level and the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

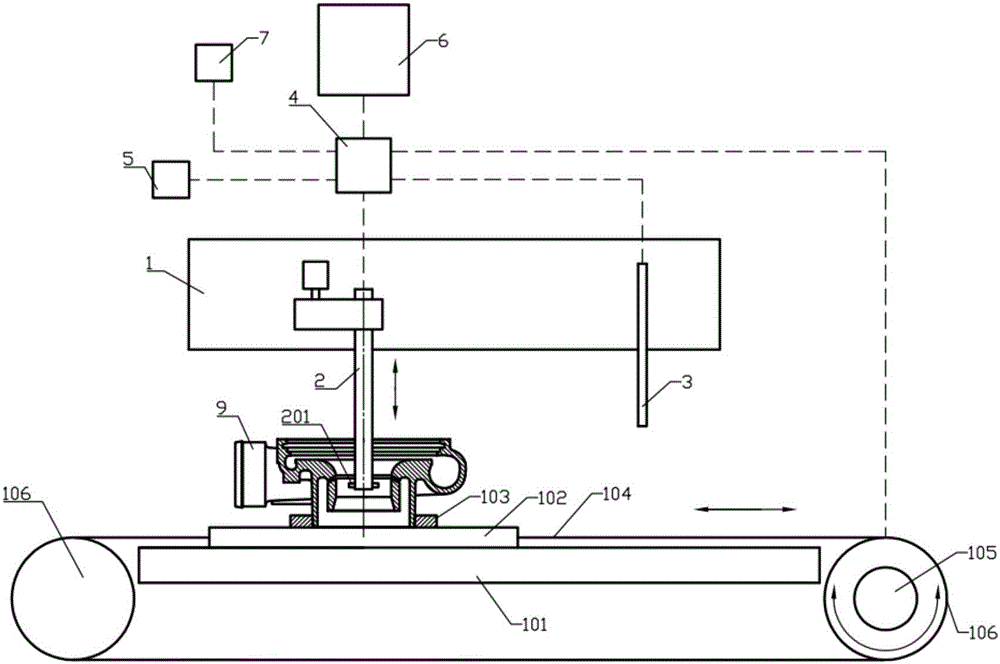

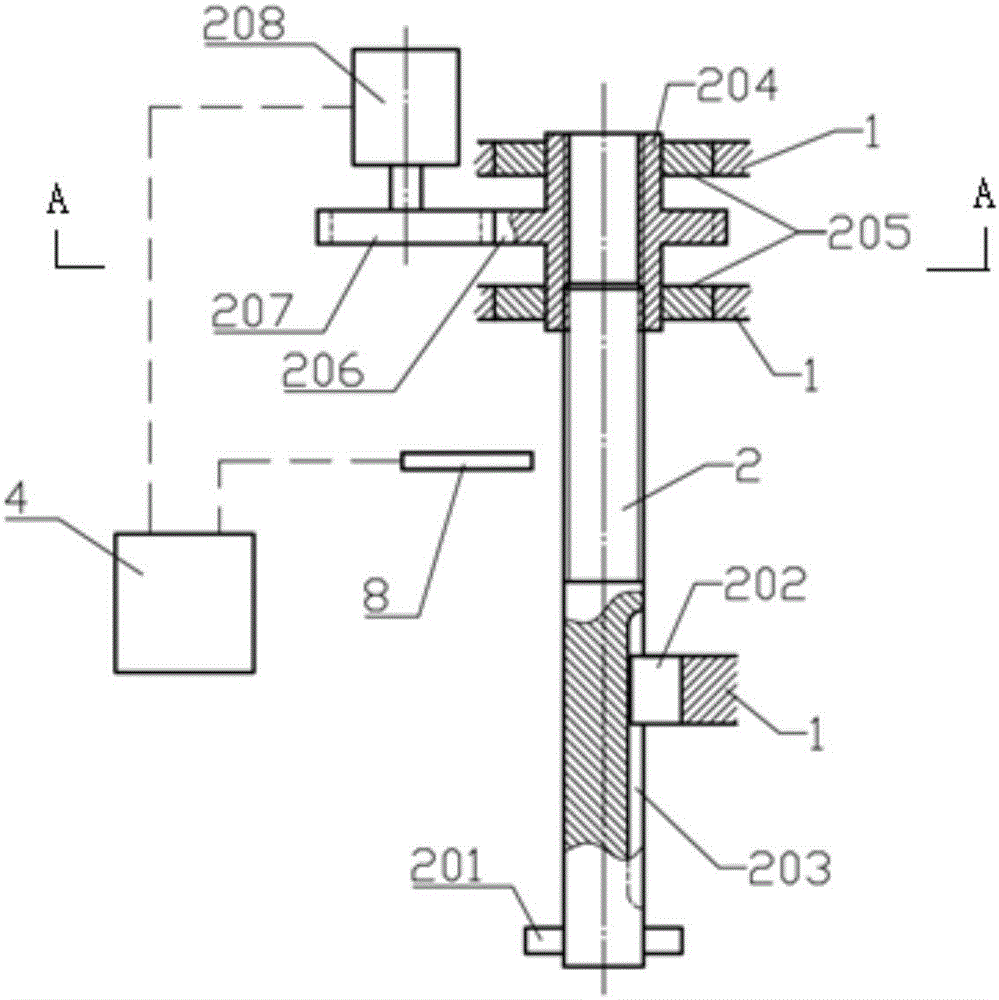

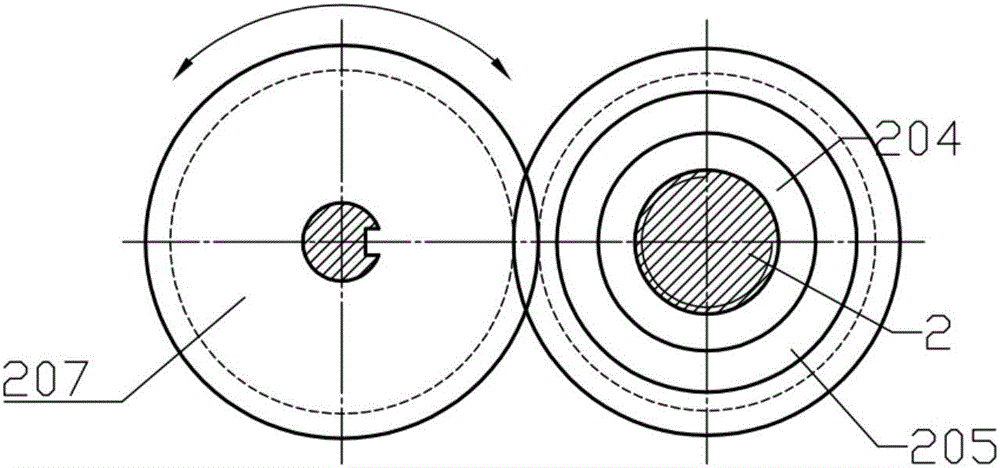

[0026] like Figure 1-4 As shown, a turbocharger casing inspection system includes a frame 1, a displacement sensor 8, a horizontal reference detection platform 101, a workpiece conveying device, a measuring device, a coding device 3 and a control device.

[0027] The measuring device and the coding device 3 are installed on the frame 1, and the frame 1 is provided with a displacement sensor 8 and a horizontal reference detection platform 101, and the working surface of the horizontal reference detection platform 101 is in a horizontal state.

[0028] The workpiece conveying device includes a detection mobile platform 102, a workpiece positioning block 103, a conveyor belt 104, a cylinder 105 and a first motor 106; The conveyor belt 104 is connected to the roller 105, and at least one of the rollers 105 is equipped with a first motor 106; the upper surface of the detection mobile platform 102 is provided with a workpiece positioning block 103, and the workpiece positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com