A Q245R material nondestructive stress test method

A non-destructive testing and stress technology, applied in the field of non-destructive testing of Q245R materials, can solve the problems of inability to find serious stress concentration, inability to achieve overall stress state, and high requirements for equipment and pipeline surfaces, saving inspection costs and facilitating re-inspection , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

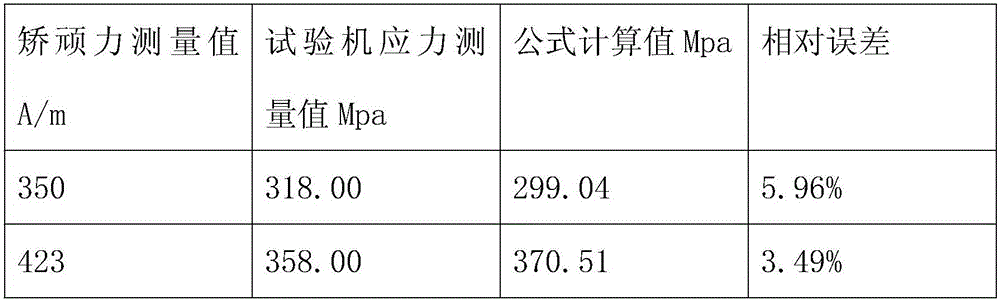

Embodiment 1

[0034] The sample material is Q245R, and the state is the hot-rolled state in the delivery state. Select the central part of the sample for magnetization measurement.

[0035] The formula under the corresponding delivery state:

[0036]

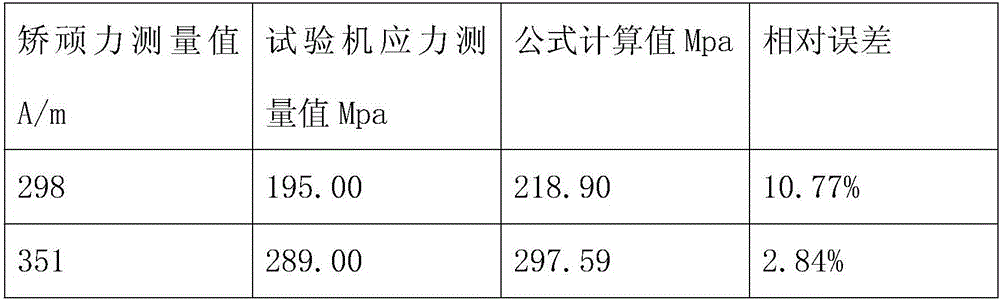

Embodiment 2

[0038] The sample material is Q245R, and the state is annealed. Select the central part of the sample for magnetization measurement.

[0039] The formula in the corresponding annealed state:

[0040]

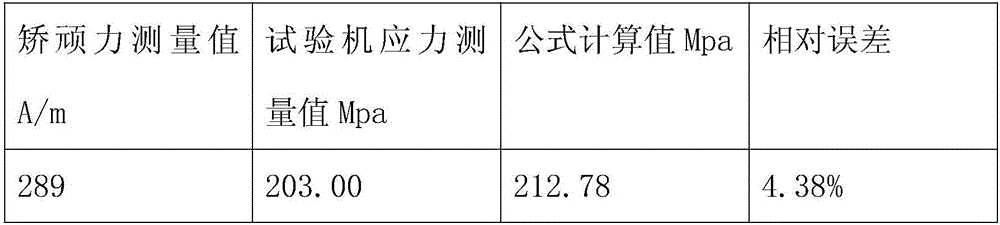

Embodiment 3

[0042] The sample material is Q245R, and the state is aging at 250°C. Select the central part of the sample for magnetization measurement.

[0043] The corresponding formula under aging at 250°C:

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com