Oil-gas separation device for air leakage test of engine piston

A technology of piston air leakage and separation device, which is applied in the field of test equipment and oil-gas separation device for engine piston air leakage test. Efficiency, meet the oil and gas separation requirements, increase the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

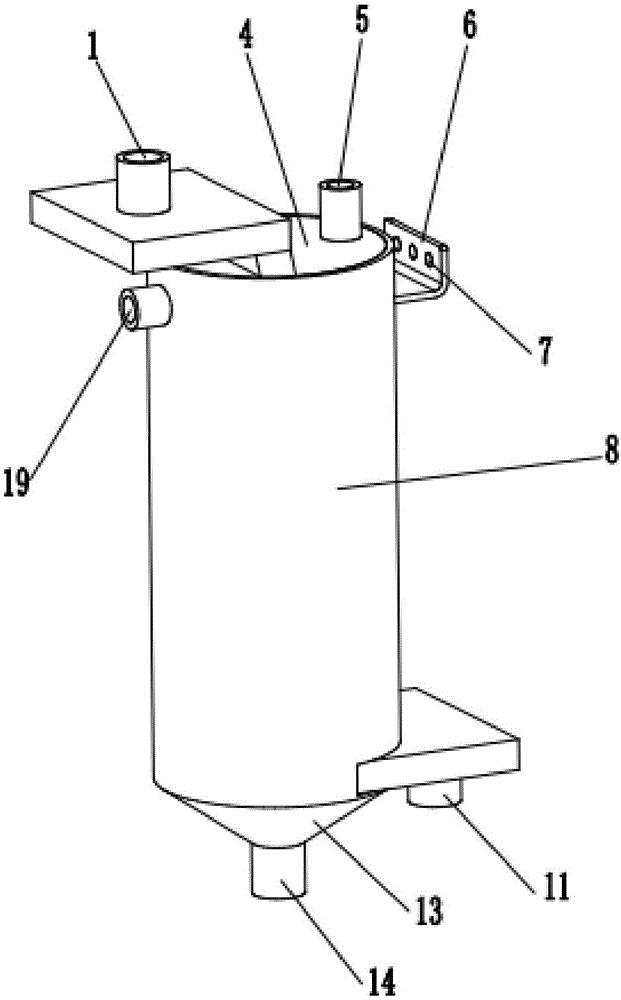

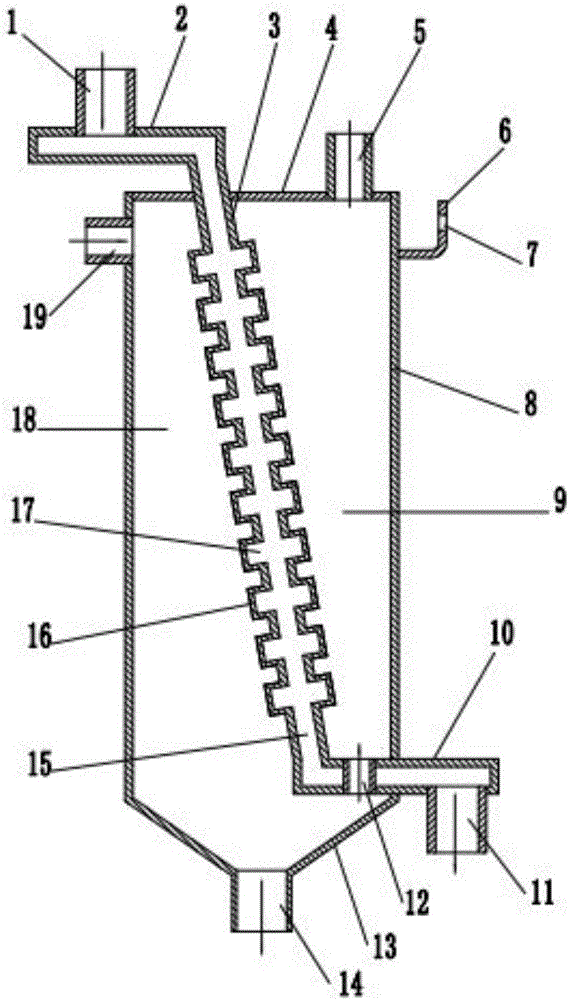

[0027] refer to figure 1 and figure 2 According to the present invention, an oil-air separation device for engine piston air leakage test includes an oil-air separator body 8, a radiator and a cooling water control system.

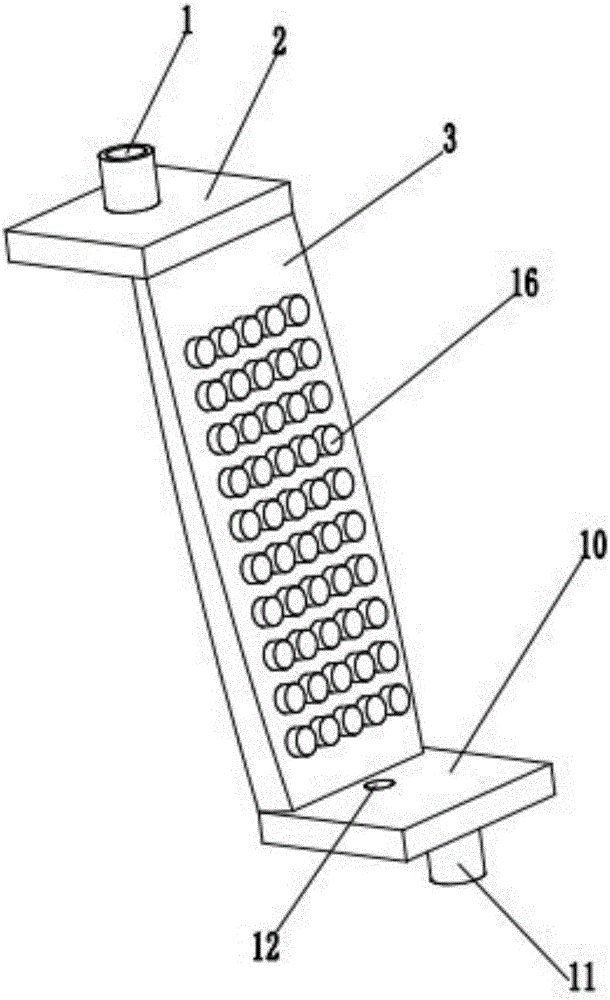

[0028] refer to figure 2 and figure 2 , the oil-gas separator body 8 is a cylindrical shell structure, the top cover 4 of the oil-gas separator body 8 is a circular flat plate, and the right side of the top cover 4 is provided with a cylindrical The oil and gas outlet 5 of the top cover 4 is provided with a through hole for installing the flow cavity 3 in the radiator. The external dimensions at this place are equal. On the left cylinder wall at the upper end of the oil-gas separator body 8, a cylindrical oil-gas inlet 19 connected to the cylinder wall is provided, and a L is welded on the outside of the right cylinder wall opposite to the oil-gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com