Waxing device and method

A wax block and frame technology, applied in the direction of grinding feed motion, grinding machine, grinding machine parts, etc., can solve the problems of rough end face of textile paper tube, affecting the unwinding rate of spinning fibers, etc., and achieve good fluidity. , The effect of waxing is good, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

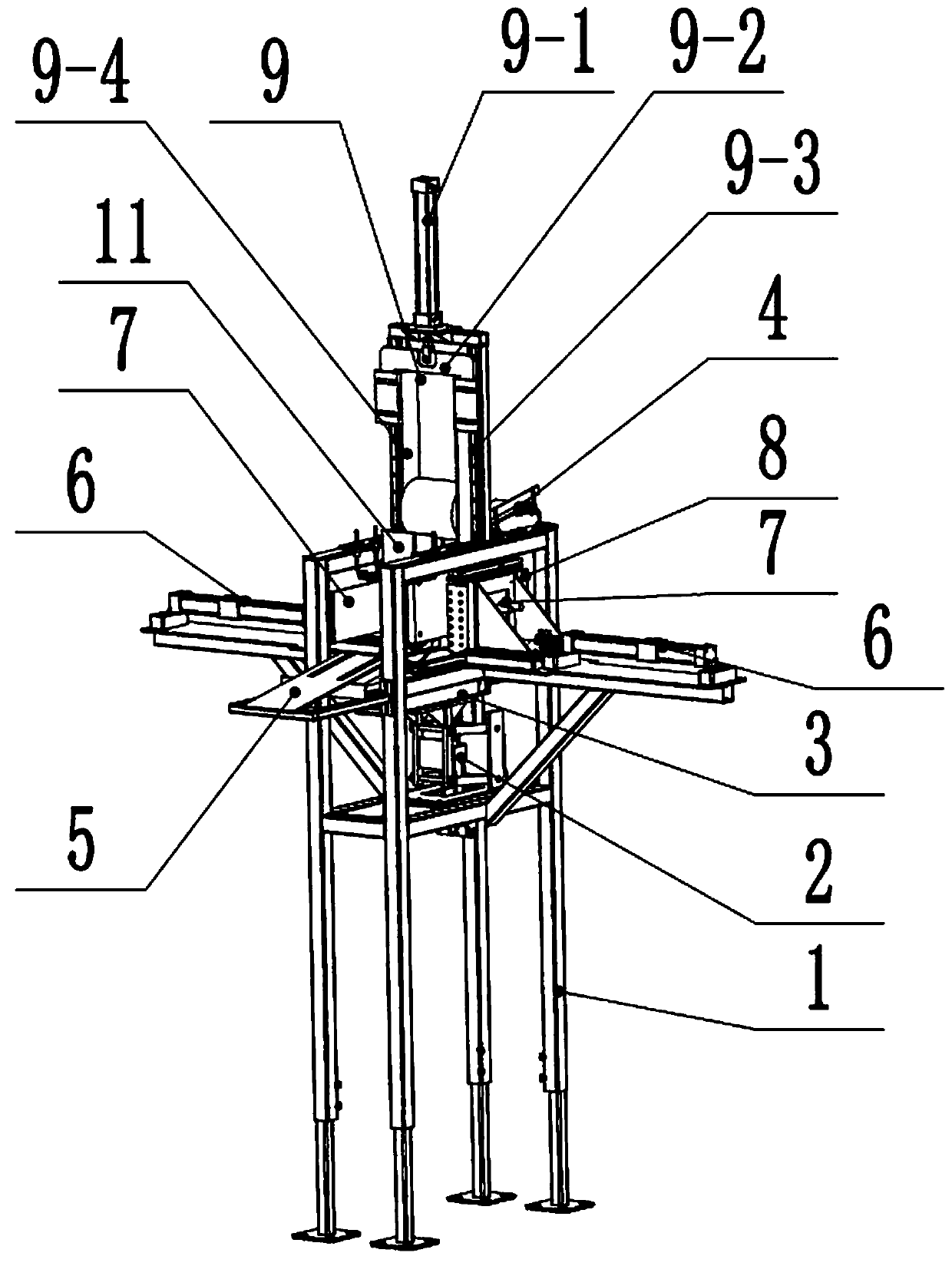

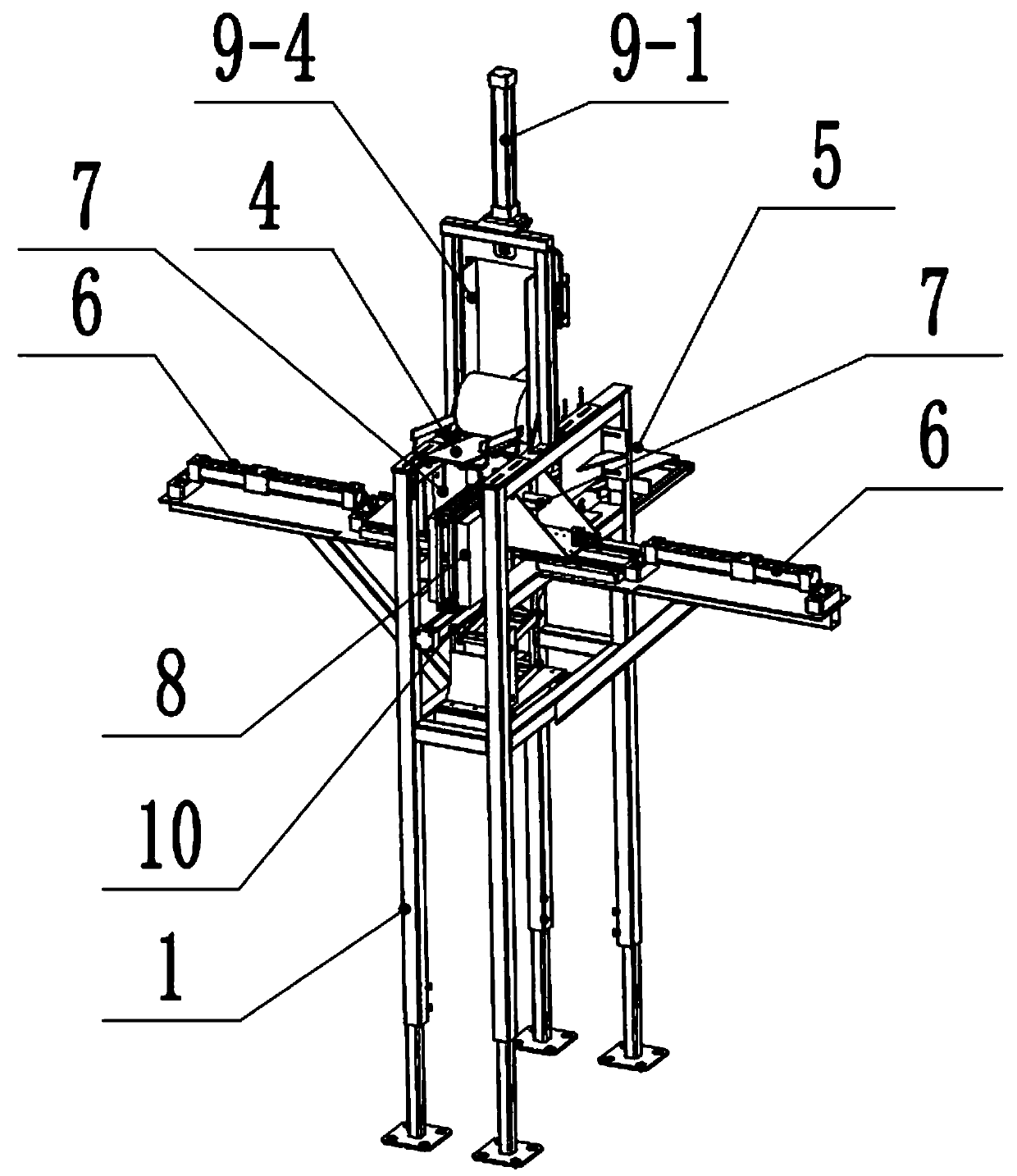

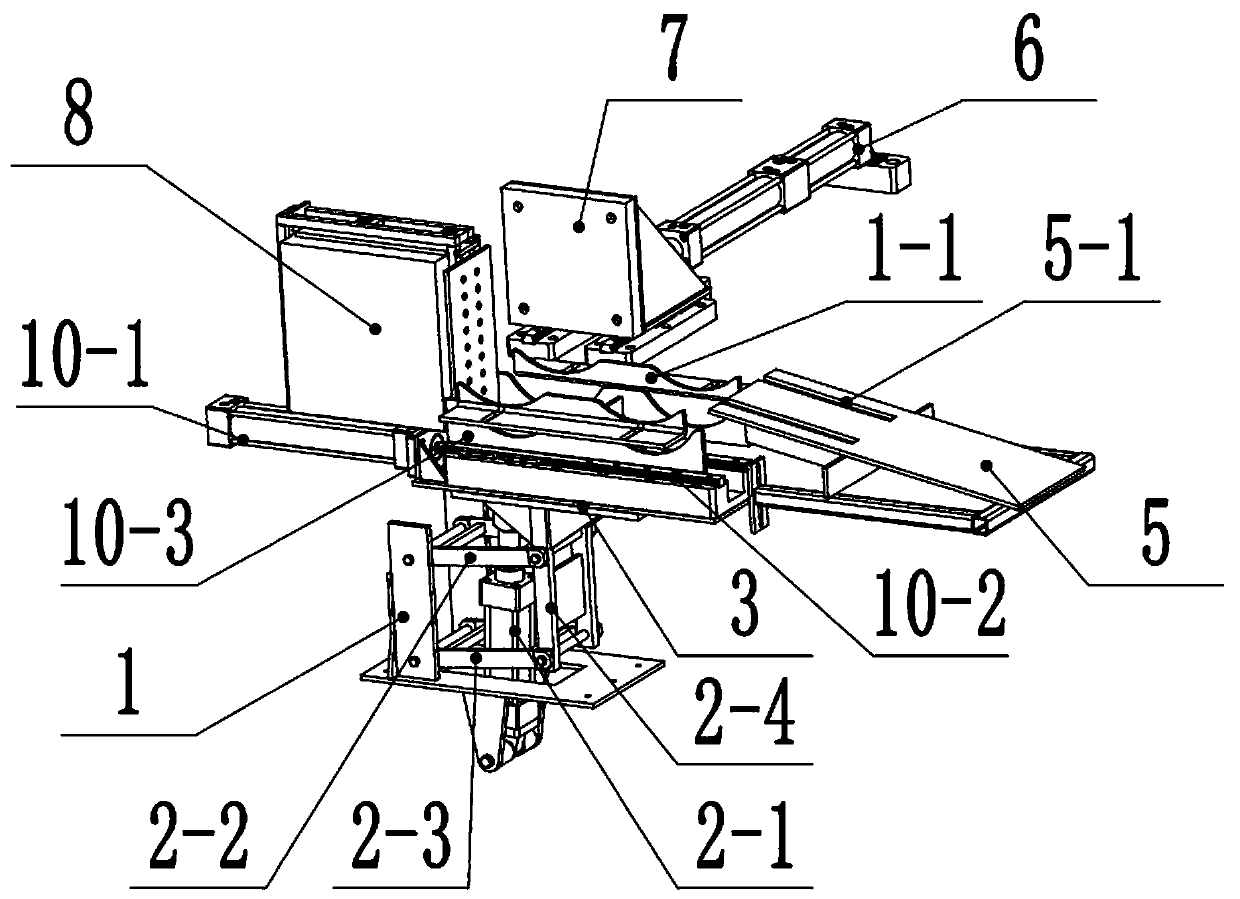

[0029] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0030] Such as figure 1 and 2 , a waxing device, comprising a steel frame 1, the frame 1 is provided with two sets of symmetrically arranged heating plates 7, the heating plate 7 is provided with a wax layer, and the two sets of heating plates 7 are parallel to each other, are set vertically. Heating wire or other heating devices are installed in the heating plate 7 .

[0031] The frame 1 is also provided with a clamping mechanism for driving two sets of heating discs 7 to clamp the cylindrical workpiece between them; the axis of the workpiece is horizontal from left to right.

[0032] The frame 1 is also provided with a moving mechanism, which is used to drive the workpiece to move relative to the two sets of heating plates 7, so as to complete the waxing work on the end of the workpiece.

[0033] Specifically, the moving mechanism includes a lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com