Shale permeability testing device and method based on liquid pressure pulses in presence of ultrasonic waves

A technology of liquid pressure and testing equipment, which is applied in the direction of measuring equipment, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of inability to test the permeability of shale cores, etc., and achieve the perfect effect of ultrasonic on shale seepage characteristics Influence mechanism, short test time and small pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

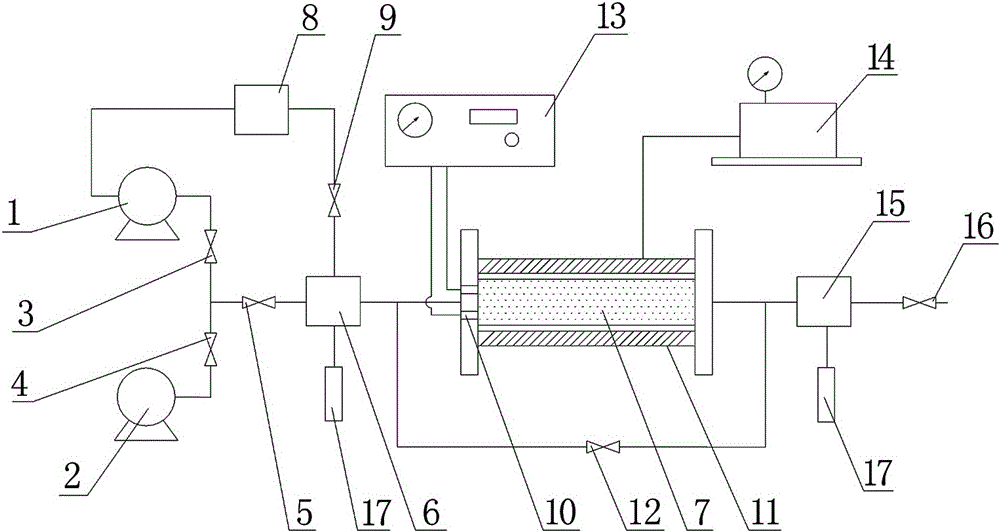

[0033] Such as figure 1 As shown, a shale permeability test device based on liquid pressure pulse under the action of ultrasonic waves, it includes a constant pressure constant flow pump 1, a vacuum pump 2, a core holder 11, an upstream standard chamber 6 and a downstream standard chamber 15, the The upstream standard chamber 6 communicates with the liquid inlet end of the rock core holder 11, the downstream standard chamber 15 communicates with the liquid outlet end of the rock core holder 11, and the node between the upstream standard chamber 6 and the rock core holder 11 liquid inlet A balance control valve 12 is connected between the node of the downstream standard chamber 15 and the outlet end of the rock core holder 11, and a pressure sensor 17 is connected to the upstream standard chamber 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com