Textile defect detection method based on hierarchical clustering and Gabor filtering

A technology of hierarchical clustering and defect detection, which can be used in optical testing of defects/defects, measuring devices, material analysis by optical means, etc., and can solve the problem of low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

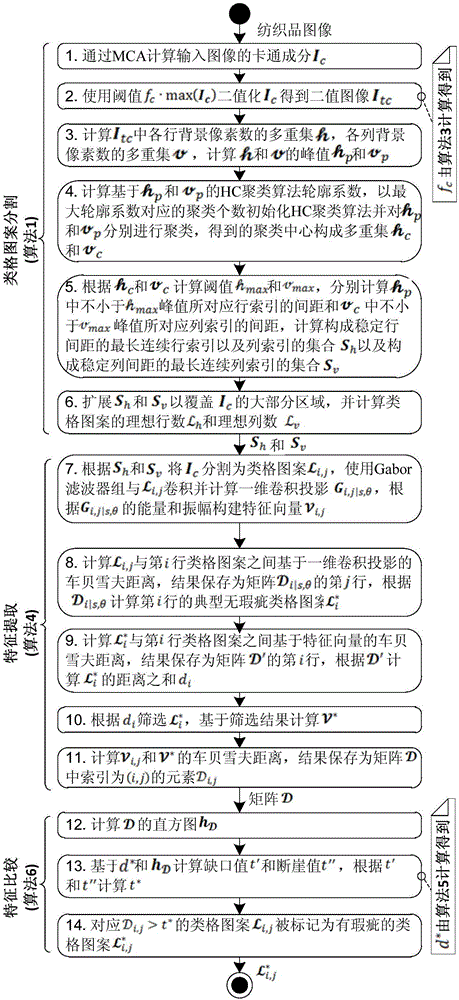

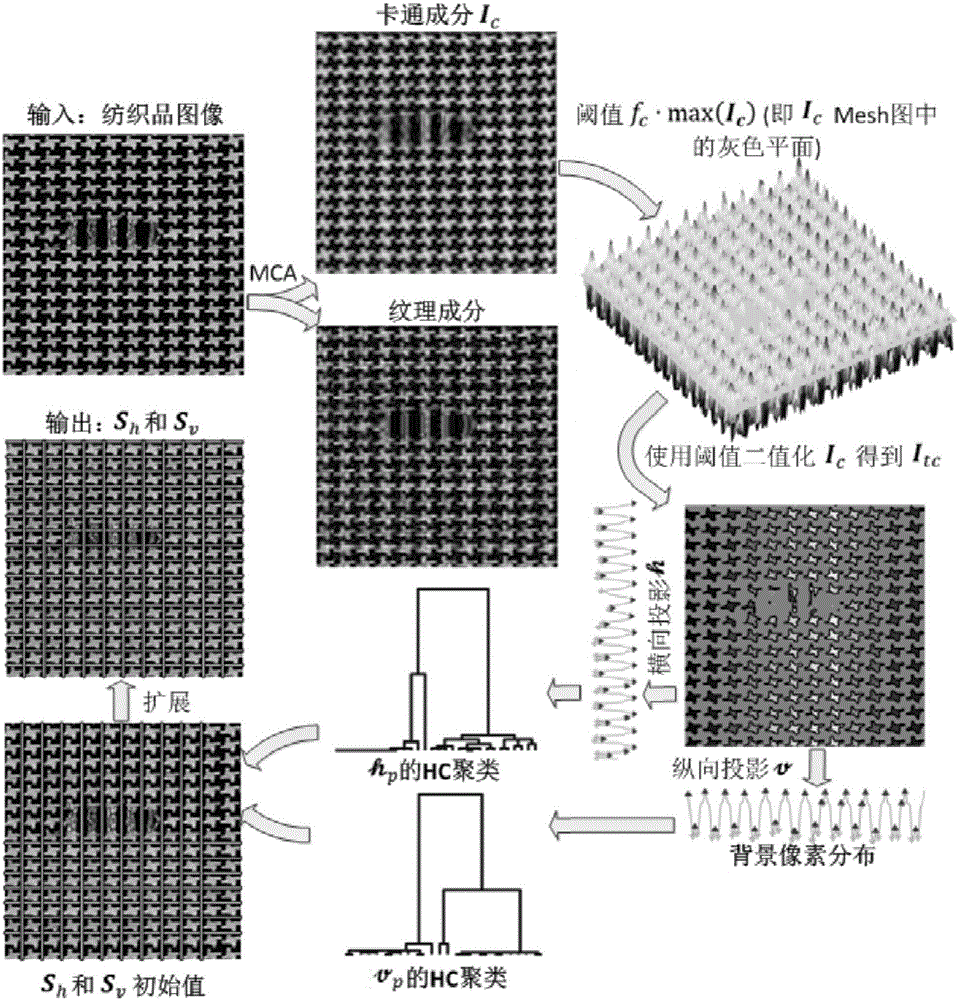

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail now in conjunction with accompanying drawing.

[0047] In order to make the statement clear, some symbols and concepts involved in the present invention are now focused on defining.

[0048] 1. Represents a set of positive integers.

[0049] 2. Represents the set of integers including zero.

[0050] 3. Represents the set of positive real numbers including zero.

[0051] 4. Represents the set of real numbers including zero.

[0052] 5. T represents matrix or vector transpose.

[0053] 6. Express ratio small largest integer, such as

[0054] 7. Indicates that the sequence of operands is concatenated to produce a vector, such as a scalar v 1 = 1 and the vector for scalar s 1 =8,s 2 = 1, s 3 = 5, for vector

[0055] 8. in

[0056] 9. Cb(v 1 , v 2 ) represents a vector v with the same dimension 1 with v 2 The Chebychev distance (Chebychev distance).

[0057] 10.{a i} represents t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com