Device and method for monitoring aging degree of rubber base plate for rail structure

A technology of rubber backing plate and aging degree, which is applied in the direction of measuring device, measurement of property and force applied to piezoelectric devices, force/torque/power measuring instrument, etc. System complexity and other issues, to achieve the effect of ensuring long-term service, significant piezoelectric effect, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] This embodiment uses an experimental method to illustrate the device and method of the present invention.

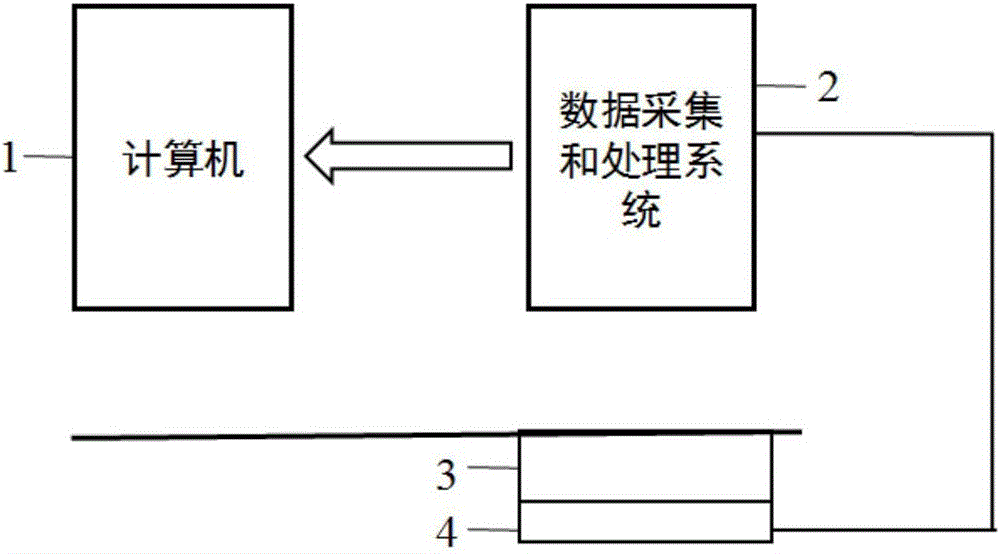

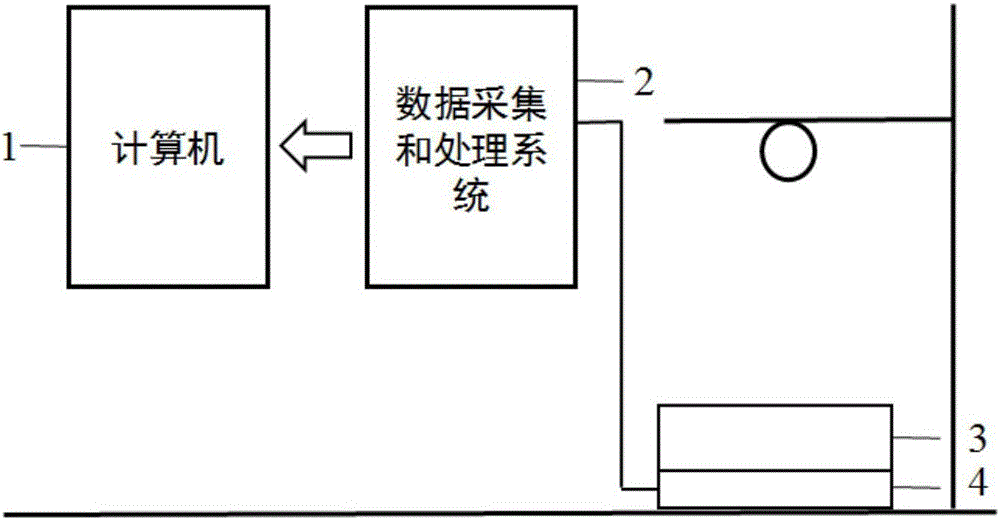

[0039] Such as figure 2 As shown, the piezoelectric sensor 4 is laid under the rubber pad 3 with different aging degrees, the piezoelectric sensor 4 is connected to the data acquisition and processing system 2 by lead wires, and the data acquisition and processing system 2 is connected to the computer. Use the ball falling device to make the ball drop freely from the same height and position to the rubber backing plate. At the same time, use a high-speed camera to shoot the ball falling and rebounding process, and observe and record the output voltage of the piezoelectric sensor 4 on the computer 1. Signal.

[0040] The piezoelectric sensor 4 adopts a flexible PZT piezoelectric sensor.

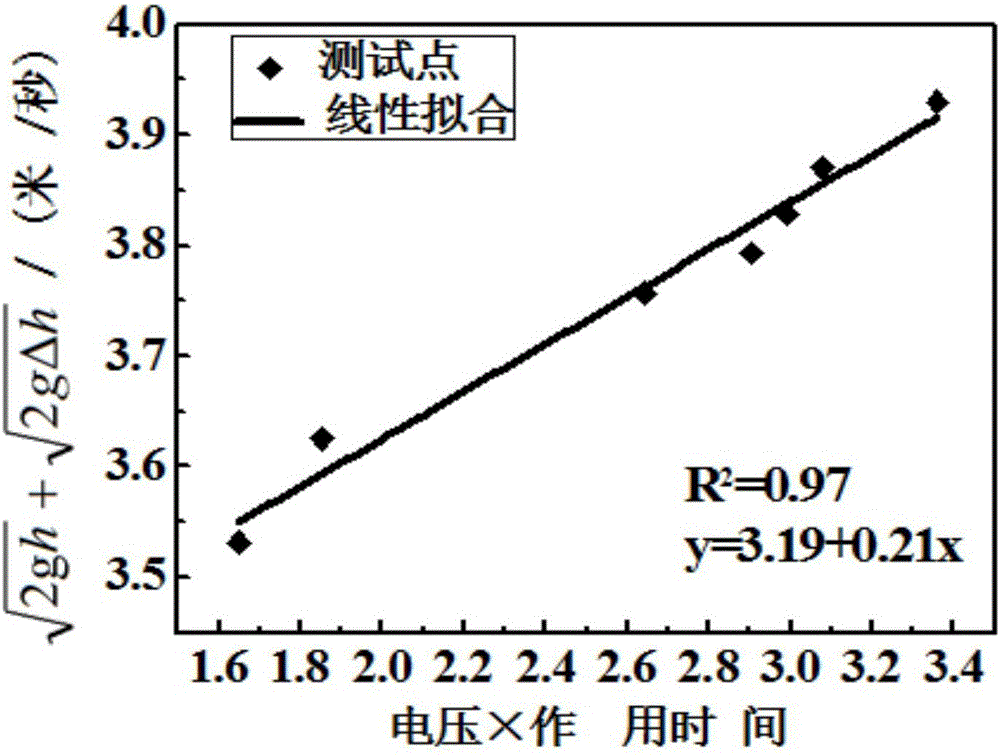

[0041] A batch of rubber pads with fixed dimensions is heated at different temperatures and times by using an oven accelerated aging method to prepare a batch of rubber pads wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com