Liquid chromatograph temperature control device and dehumidifying method

A liquid chromatograph and temperature control equipment technology, which is applied in the liquid chromatograph temperature control equipment and moisture removal field, can solve the problems of increasing the cost of the instrument, affecting the appearance, complex processing technology, etc., to achieve the effect of enhancing refrigeration and improving the appearance degree, the effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

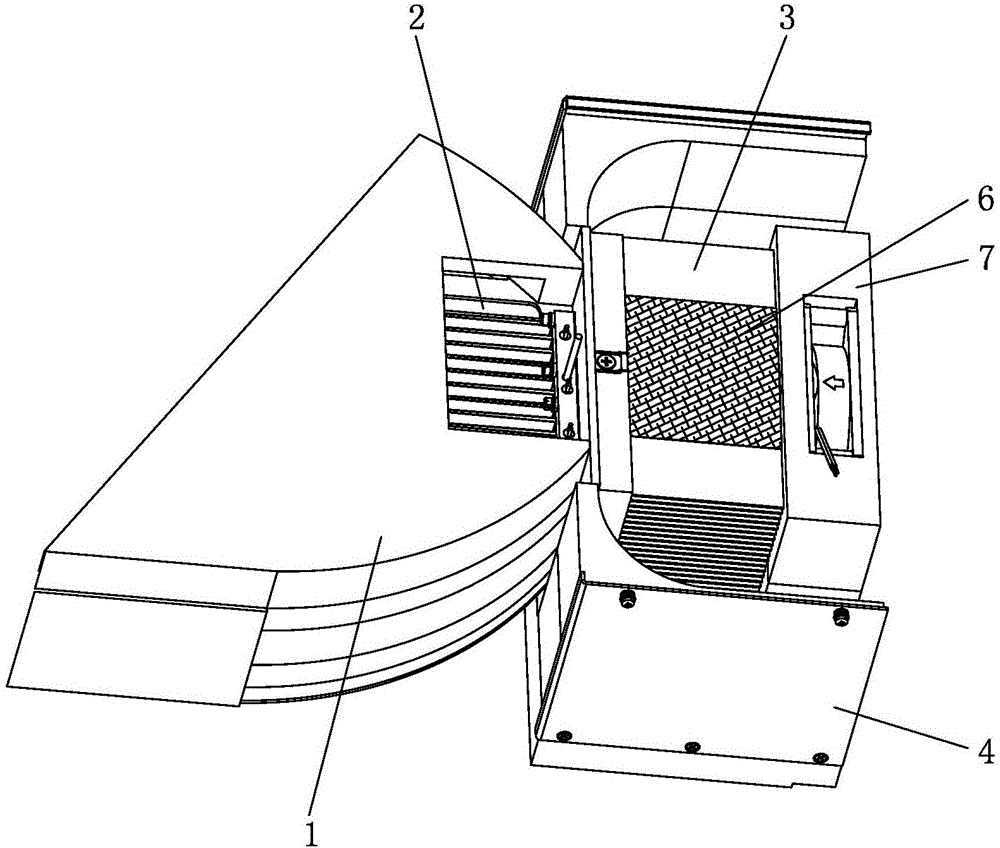

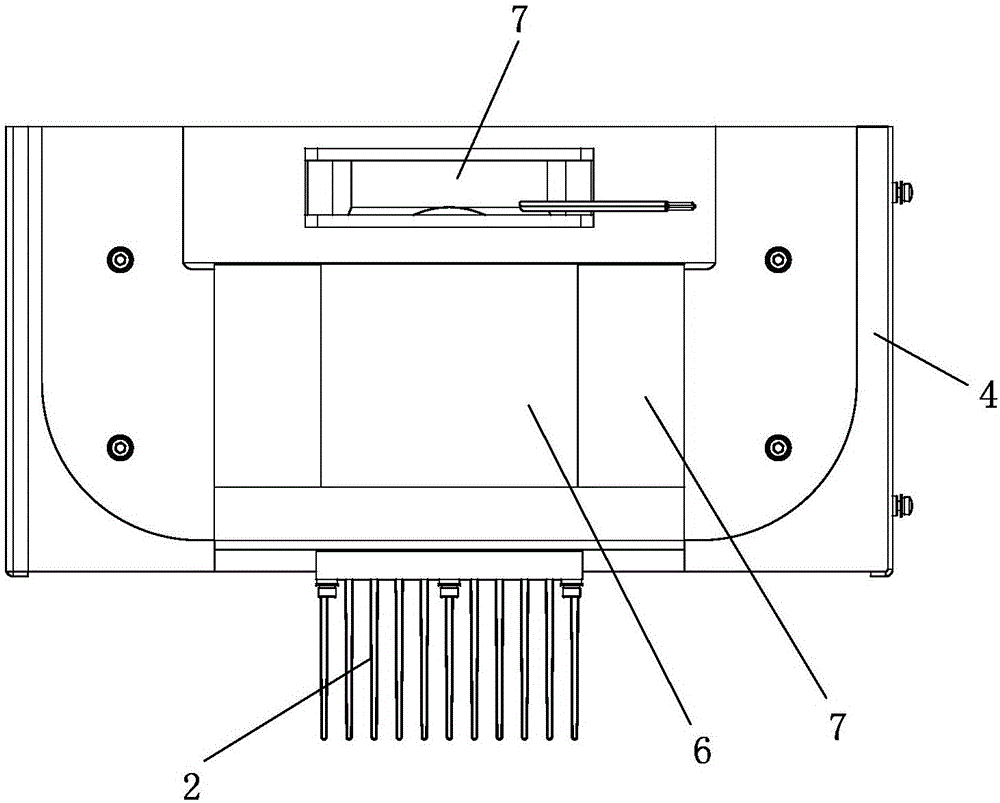

[0030] The following are specific embodiments of the present invention and in conjunction with the attached Figure 1-5 , The technical scheme of the present invention is further described, but the present invention is not limited to these embodiments.

[0031] A liquid chromatograph temperature control device, comprising a constant temperature chamber 1, a cooling body 2 and a cooling block 3, the cooling body 2 and cooling block 3 are fixed on a support seat 4, and a semiconductor cooling sheet 5 is connected to the cooling body 2 and the heat dissipation block. Block 3, the cooling body 2 is placed in the constant temperature chamber 1, and the constant temperature chamber 1 is in a sealed state, and the cooling body 2 and the cooling block 3 are wrapped with water-absorbing materials 6 .

[0032] Specifically, the semiconductor cooling sheet 5 is pasted between the cooling body 2 and the heat dissipation block 3 .

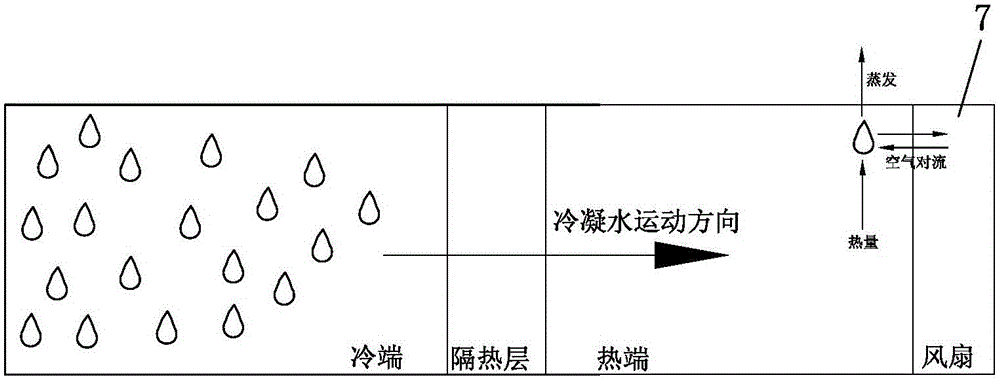

[0033] More specifically, the cold end of the semiconduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com