Microseismic monitoring sensor installation device and installation method

A technology for microseismic monitoring and installation, which is applied to seismic signal receivers and other directions, can solve problems such as increased noise interference, increased monitoring costs, and impact on positioning accuracy, and achieves the effect of ensuring positioning accuracy, monitoring effects, and convenient maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

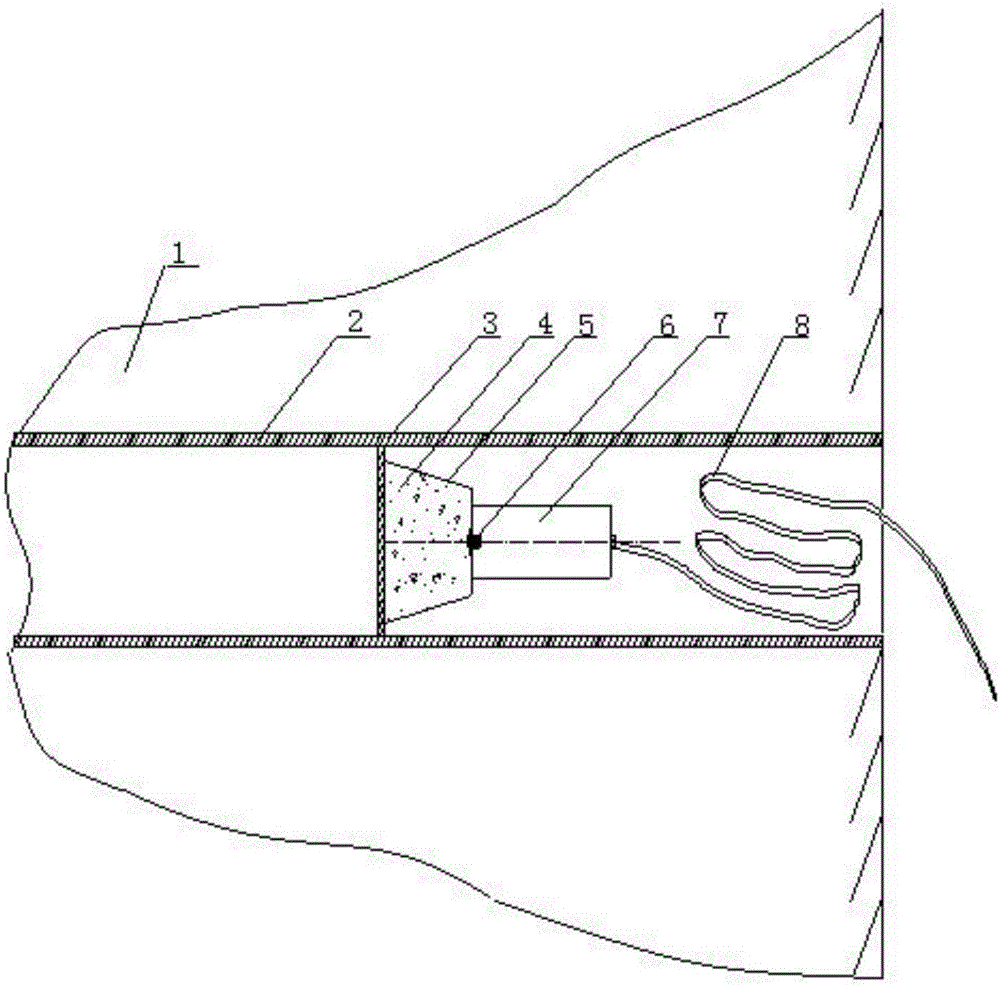

[0031] Such as figure 1 As shown, a microseismic monitoring sensor installation device of the present invention includes a fixed sleeve 2, an anchoring agent container 5 and a microseismic monitoring sensor 7; the fixed sleeve 2 is installed in the monitoring hole drilled on the rock mass 1, A positioning mounting plate 3 is arranged laterally on the side of the fixed sleeve 2 close to the opening of the monitoring hole; one end of the anchoring agent container 5 containing the anchoring agent 4 is provided with an opening, and the opening end is closely attached to the positioning mounting plate 3 through the anchoring agent 4 ; The other end of the anchoring agent container 5 is fixedly connected with the microseismic monitoring sensor 7 .

[0032] The fixed sleeve 2 is made of a steel pipe with a wall thickness of 3 to 5 mm, and its outer diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com