Light guide plate

A light guide plate and technology in the light guide plate, applied in the field of light guide plates, can solve the problems of reducing equipment endurance, waste, and user reception, and achieve the effects of simple structure, improved utilization rate, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

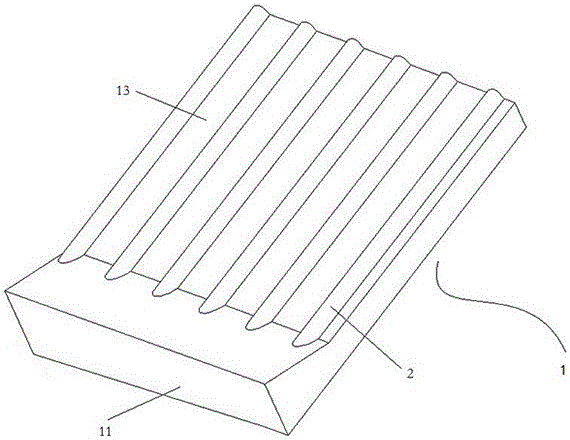

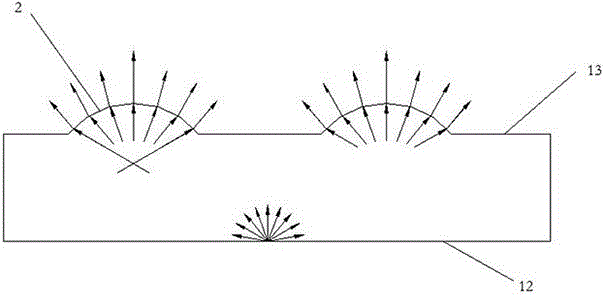

[0026] as attached figure 1 And attached figure 2 As shown, the bottom of the light guide plate 1 is the incident surface 11 , and by disposing the light source on the edge of the incident surface 11 , the light emitted by the light source can enter the interior of the light guide plate 1 through the incident surface 11 . Both sides, the top and the bottom of the light guide plate 1 are reflective surfaces 12, and the reflective surface 12 can reflect the light irradiated on the surface at a certain angle. The upper part of the light guide plate 1 is a light-transmitting surface, and the light-transmitting surface can allow internal light to pass through.

[0027] A plurality of strip-shaped arc-shaped protrusions, ie light-concentrating structures 2 , are arranged on the light-transmitting surface. Different light-concentrating structures 2 are arranged longitudinally at equal distances, and the distance between the light-concentrating structures 2 is 150 μm. The height of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Bump height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com