High-power liquid cooling opto-isolator

An optical isolator and isolator technology, applied in the field of optical isolators, can solve the problems of poor heat dissipation effect and low isolation, and achieve the effect of improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

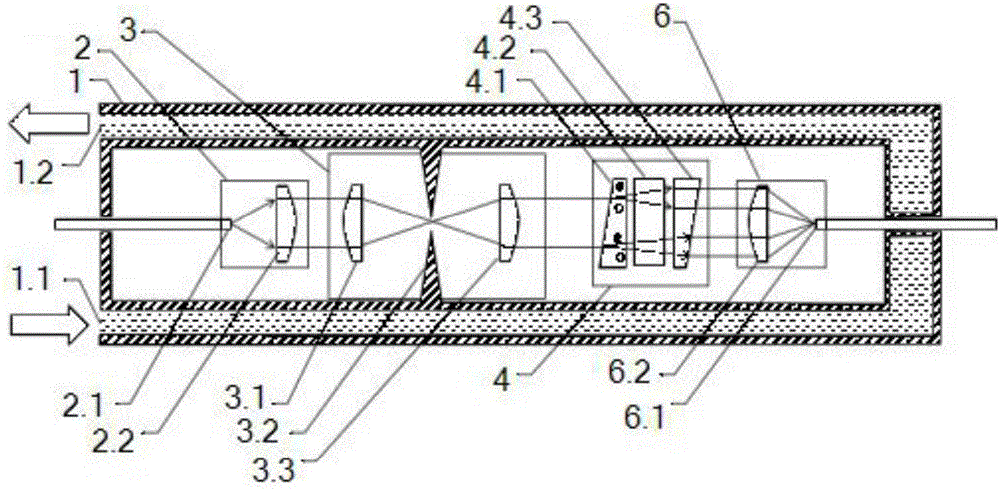

[0024] Such as figure 2 As shown, a high-power liquid-cooled optical isolator includes a first filter 3 and an optical isolator core 4 in sequence along the incident optical axis of the forward light, and the first filter 3 and the optical isolator core 4 are all arranged on In the water-cooled packaging device 1, the light input into the first filter 3 and the light beam output by the optical isolator core 4 are both approximately parallel light beams with a divergence angle less than 5 degrees.

[0025] The first filter 3 includes an aperture a and lens b3.1 and lens c3.3 located on both sides of the aperture, and the first through hole 3.2 on the aperture a is located at the common focal plane of lens b3.1 and lens c3.3 superior. Diaphragm a can filter out light rays whose angle with the incident optical axis of the forward light is too large.

[0026] The optical isolator core 4 includes a first birefringent crystal 4.1, a Faraday rotator 4.2 and a second birefringent c...

Embodiment 2

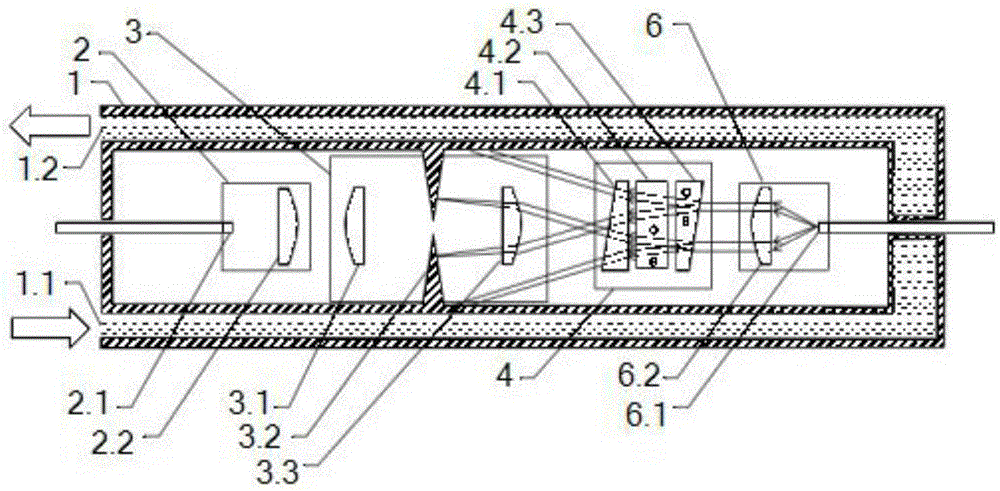

[0034] Such as image 3 As shown, a high-power liquid-cooled optical isolator includes a first filter 3 and an optical isolator core 4 in sequence along the incident optical axis of the forward light, and the first filter 3 and the optical isolator core 4 are all arranged on In the water-cooled packaging device 1, the light input into the first filter 3 and the light beam output by the optical isolator core 4 are both approximately parallel light beams with a divergence angle less than 5 degrees.

[0035] The first filter 3 includes an aperture a and lens b3.1 and lens c3.3 located on both sides of the aperture, and the first through hole 3.2 on the aperture a is located at the common focal plane of lens b3.1 and lens c3.3 superior. Diaphragm a can filter out light rays whose angle with the incident optical axis of the forward light is too large.

[0036] The optical isolator core 4 includes a first birefringent crystal 4.1, a Faraday rotator 4.2 and a second birefringent cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com