Photovoltaic modules

A photovoltaic module, white technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as expensive high-energy ray equipment, unfavorable sustainable development of photovoltaic module manufacturers, backplane wrinkles, etc., to improve production efficiency and use power , Conducive to sustainable development, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

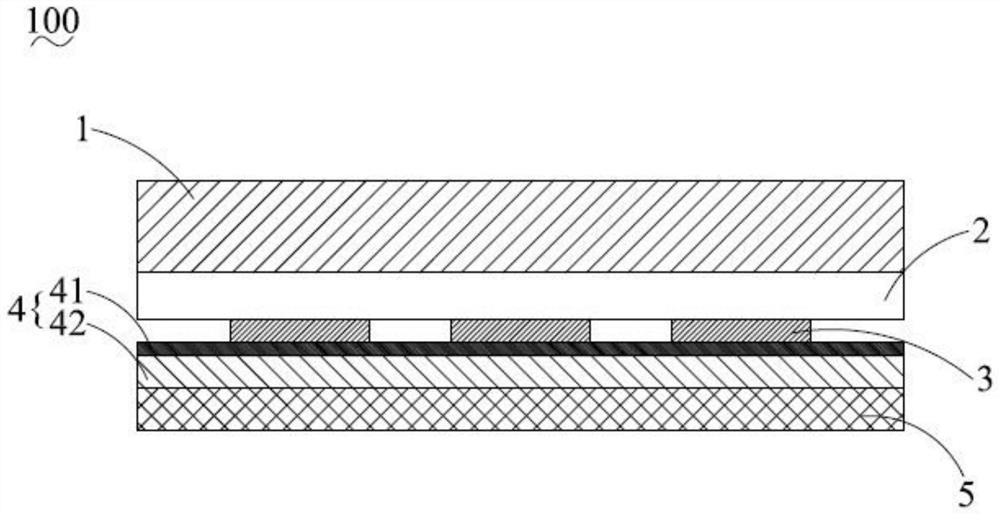

[0022] see figure 1 As shown, the present invention discloses a photovoltaic module 100 . The photovoltaic module 100 includes a glass layer 1 , a transparent encapsulation layer 2 , a cell sheet 3 , a composite encapsulation layer 4 and a photovoltaic module backplane 5 arranged in order from top to bottom.

[0023] The glass layer 1 is a high-transparency glass layer. The glass layer 1 can be ordinary glass or coated glass. The specific material can be selected by the photovoltaic module manufacturer according to actual needs, and is not limited here.

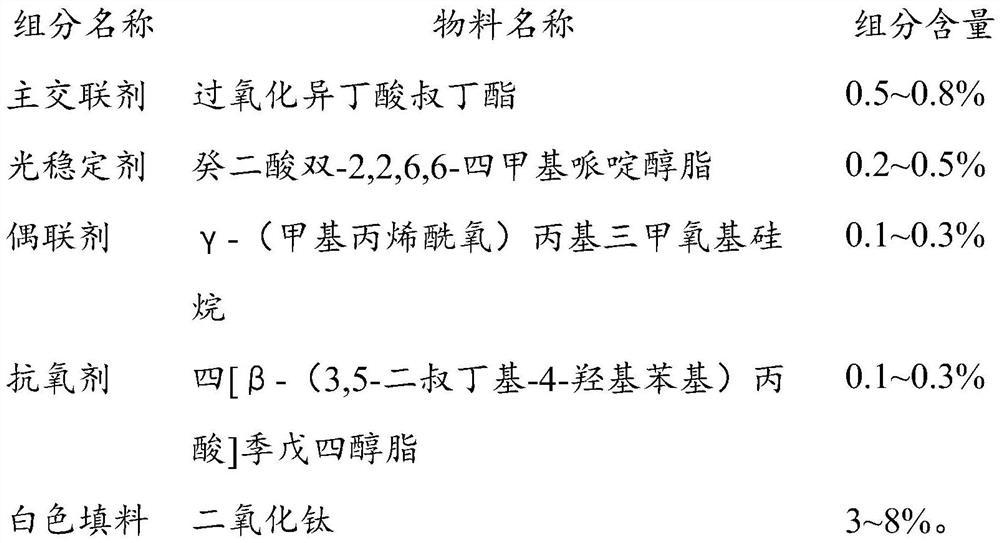

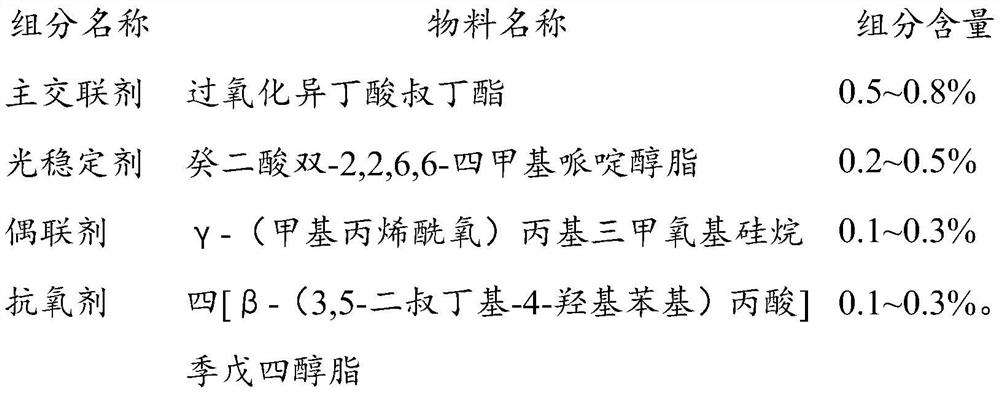

[0024] The transparent packaging layer 2 is a transparent EVA layer. Wherein, the transparent encapsulation layer 2 is made of EVA material with a vinyl acetate (VA) mass percentage of 26-33% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com