Single crystal copper fixed anode target for X-ray tube and preparing method thereof

A technology for fixing anodes and single crystal copper, applied in X-ray tube electrodes, X-ray tube components, etc., can solve problems such as cracking, affecting vacuum degree, shortening life, etc., achieve long service life, improve power and life , the effect of reducing the casting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the copper single crystal fixed anode target for the X-ray tube, the specific steps include:

[0028] Step 1, the preparation of the mold, prepare a graphite mold suitable for the size of the fixed anode target, drill holes on the side of the mold, and keep the angle of the hole consistent with the slope of the mold.

[0029] Step 2, the pre-reduction process, put the tungsten-rhenium alloy rolled sheet and high-purity copper powder in the mold, and heat and reduce in a heating furnace with hydrogen. The temperature is controlled at 900-1000°C, and the hydrogen flow is controlled to clean and restore impurities on the surface of the mold and raw materials. During this step, crystal nuclei start to form above the mold holes. At the same time, the tungsten-rhenium alloy flakes and the copper powder form a certain combination, which accelerates the growth rate of the copper single crystal in the third step.

[0030] Step 3: Casting, raise the te...

Embodiment 1

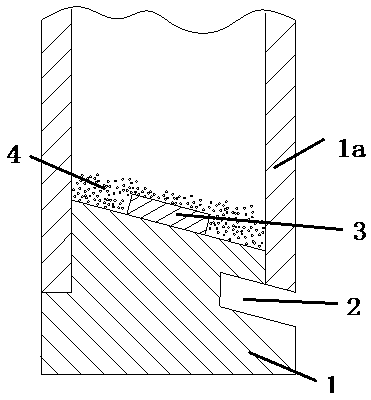

[0033] Such as figure 1 A graphite mold structure for fixing an anode target with single crystal copper for an X-ray tube shown includes a graphite base 1 and a graphite peripheral wall 1a, which are integrally combined with the graphite base 1 . The side inner holes 2 are parallel to the upper surface 1 of the graphite base, which can promote the formation of crystal nuclei. Tungsten-rhenium alloy sheet 3, high-purity copper powder 4.

Embodiment 2

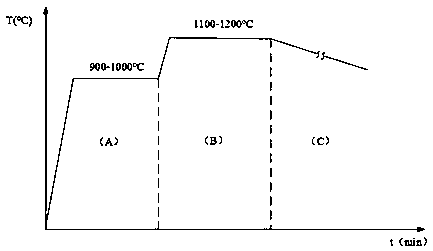

[0035] Put into the processed tungsten-rhenium alloy sheet 3 and high-purity copper powder 4 according to the proportion in the graphite mold in embodiment 1, then place in the heating furnace, according to figure 2 The process of temperature curve is heated.

[0036] In stage A, hydrogen gas is introduced and the temperature is kept at 800-900° C. During this process, impurities on the surface of the graphite boat 1 in the furnace are reduced and cleaned. The time of heating and passing hydrogen should be long enough to remove impurities on the surface of the boat and raw materials in the furnace. Through this step, the formation of crystal nuclei in parts other than the parts above the inner holes on the sides of the graphite mold can be suppressed, and the speed of nucleation in the cooling step will be accelerated. At the same time, at this stage, a bonding layer is formed between the tungsten-rhenium alloy sheet and the copper powder, which will accelerate the rate of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com