Touch control induction film resistant to Morse patterns and production method of touch control induction film

A touch sensing, anti-Mohs pattern technology, applied in the anti-Morse pattern touch sensing film and its production field, can solve problems such as affecting visual effects, achieve natural visual effects, safe and reliable touch performance, and reduce scrap rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in combination with specific embodiments.

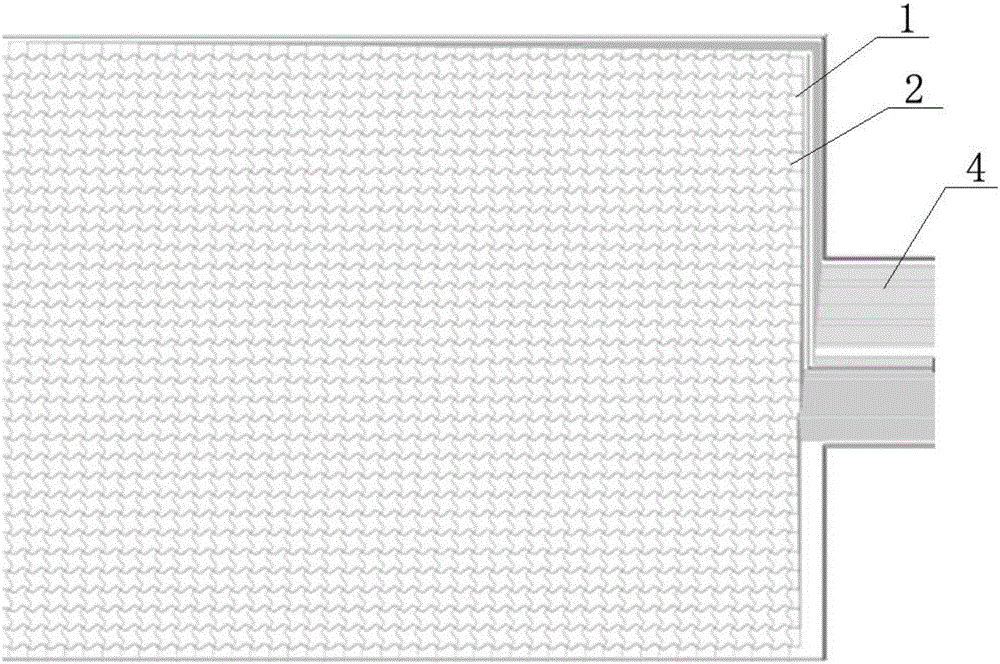

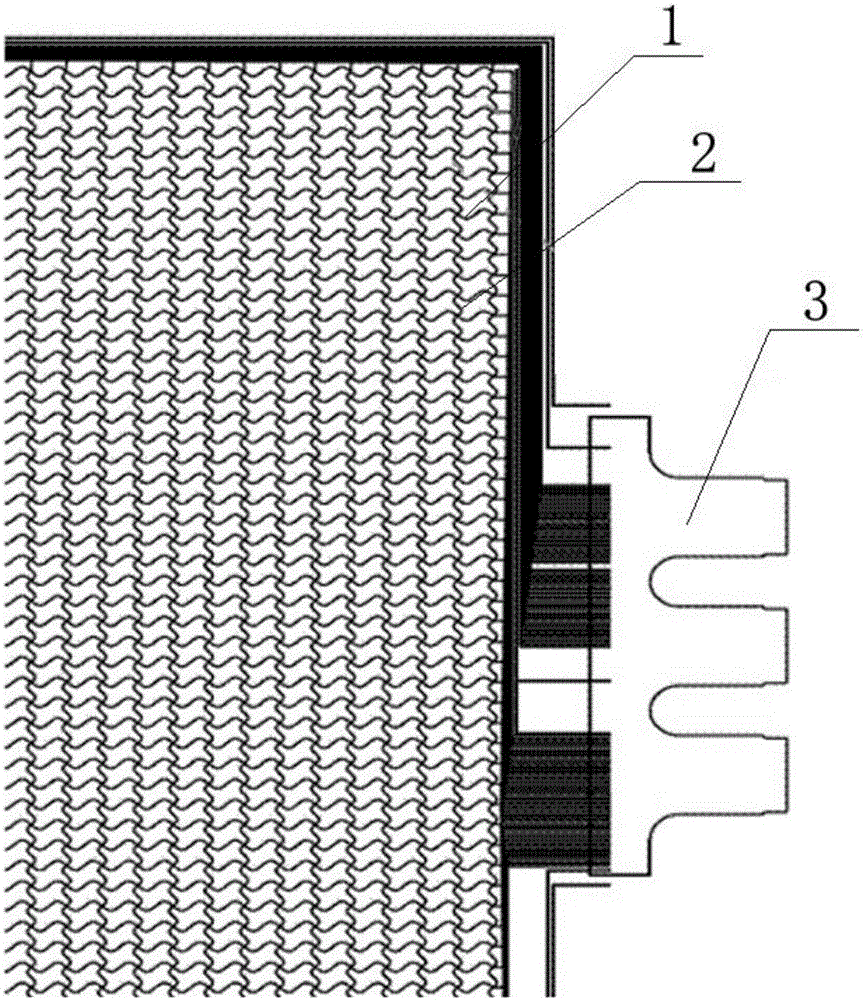

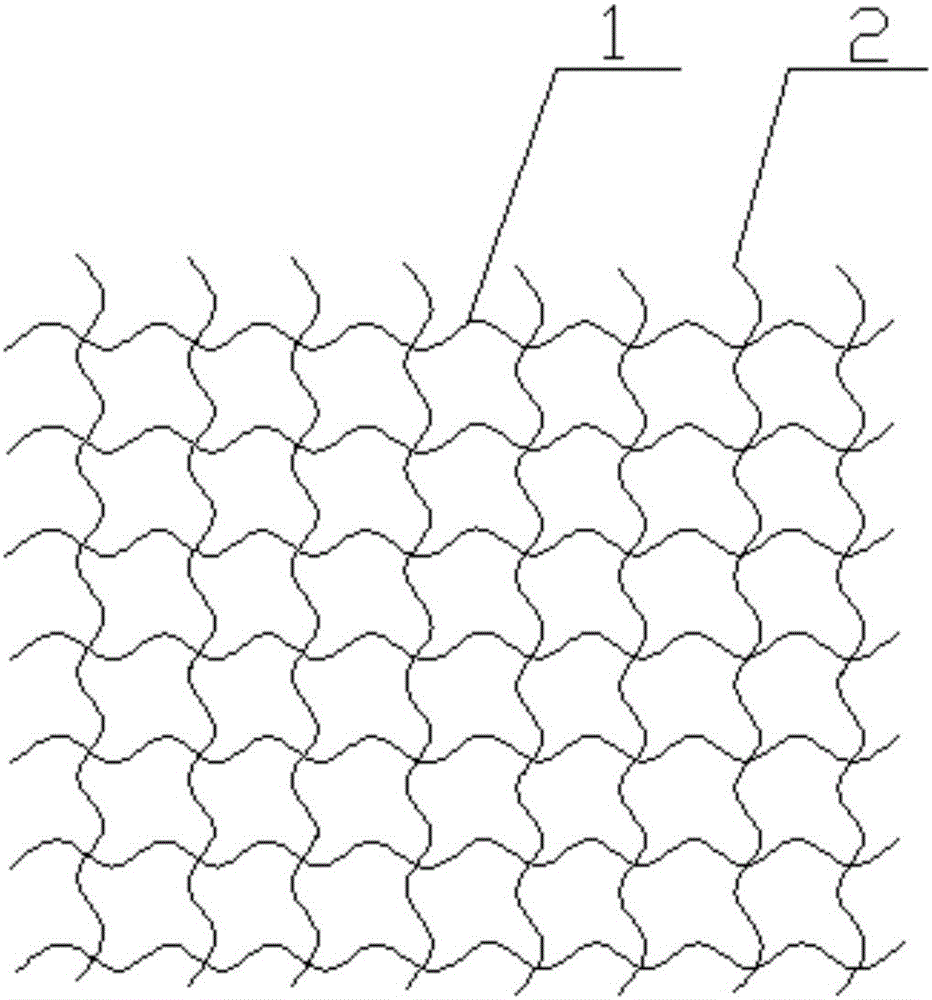

[0022] Such as Figure 1 to Figure 3 As shown, the present invention discloses a Mohs-resistant touch sensing film, including a touch sensing layer, a flexible circuit connector linking the sensing area and a controller, and the touch sensing layer is composed of several transverse wires 1 and several The longitudinal wires 2 are arranged in a warp and weft grid, the horizontal wires 1 and the longitudinal wires 2 are respectively distributed in a curved shape, and the horizontal wires 1 and the longitudinal wires 2 are combined to form a touch sensing layer. In this embodiment, both the transverse wires 1 and the longitudinal wires 2 are arranged in a sinusoidal shape with a large curvature or a semicircular wave shape with a large curvature. Arranging both the horizontal conductor 1 and the longitudinal conductor 2 in a sinusoidal wave shape with a large curvat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com