Combustion stability discrimination method based on combustion mixing coefficient and fuzzy recognition

A combustion stability and mixing coefficient technology, applied in the field of combustion flame image processing, can solve the problems of combustion instability, increase the combustion time of pulverized coal, reduce the combustion efficiency of pulverized coal, etc., and achieve the ability to identify the stability of flame combustion, accurately high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments will be described in detail below in conjunction with the accompanying drawings.

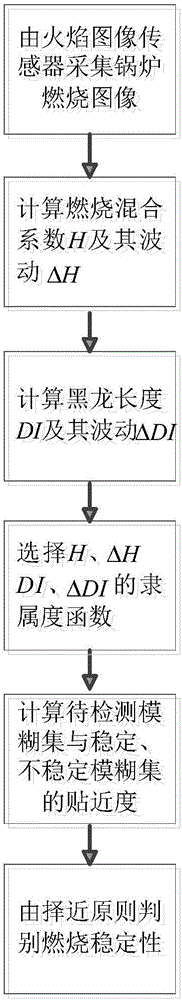

[0024] In the combustion process of the boiler, the combustion mixing coefficient directly affects the combustion status of the boiler, and the present invention adopts figure 1 The shown method judges the combustion stability, specifically including the following steps:

[0025] Step 1: Take the flame combustion area as the characteristic area, extract the corresponding grayscale parameter G and grayscale position distribution parameter D, and calculate the combustion mixing coefficient H and the fluctuation ΔH of the combustion mixing coefficient, as follows:

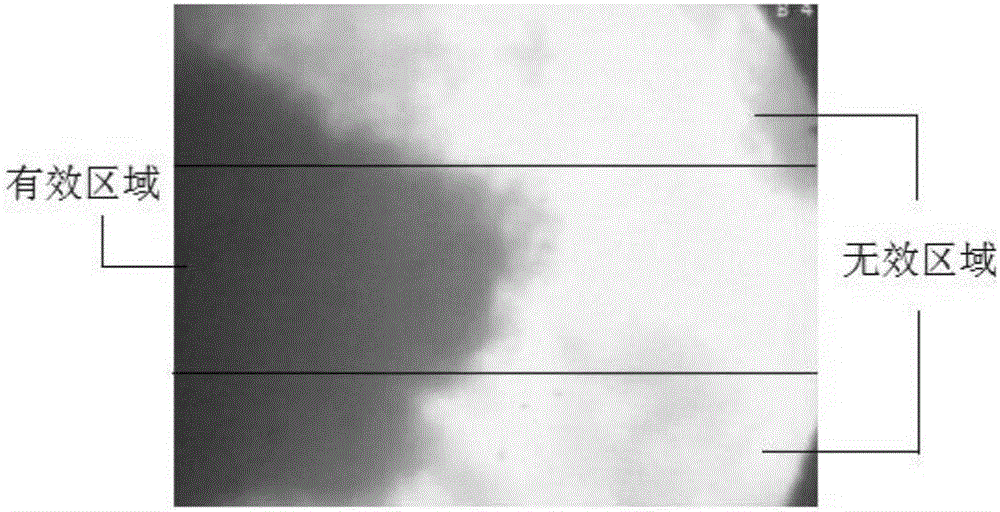

[0026] Combustion images are collected by a flame image sensor, and the embodiment of the present invention uses a combustion image with a size of 320*240, see figure 2 . Taking the flame combustion area as the characteristic area, the feature area is divided into blocks, and divided into N adjacent sub-areas w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com