Voltage-sensitive resistor element with overheat protection

A varistor, overheating protection technology, applied in the direction of varistor, overvoltage protection resistor, varistor core, etc., can solve problems such as equipment damage, potential safety hazards, faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

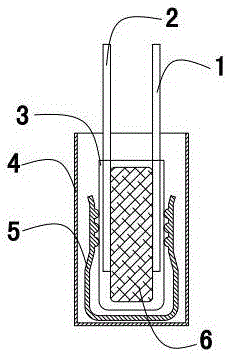

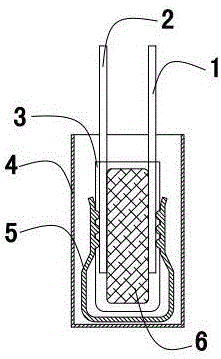

[0028] Please see figure 1 , this embodiment discloses a piezoresistive element with overheating protection, which mainly includes a first connection electrode 1 , a second connection electrode 2 , an insulating coating 3 , a casing 4 , a protection device and a piezoresistor chip 6 . In this embodiment, the electrodes on both sides of the varistor chip 6 are respectively connected to the first connecting electrode 1 and the second connecting electrode 2 . The piezoresistor chip 6 and the joints between the piezoresistor chip 6 and the first connection electrode 1 and the second connection electrode 2 are completely coated and wrapped by the insulating coating 3, and the protective device clamps the insulating coating 3 and its internal components, A conductive path exists across the protective device.

[0029] In this embodiment, the protective device is a U-shaped elastic member 5, and the two ends of the elastic member 5 correspond to the first connection electrode 1 and t...

Embodiment 2

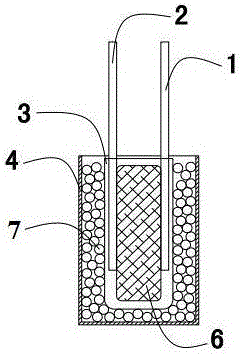

[0033] Please see image 3 , this embodiment discloses a piezoresistive element with overheating protection, which mainly includes a first connection electrode 1 , a second connection electrode 2 , an insulating coating 3 , a casing 4 , conductive particles 7 and a piezoresistor chip 6 . In this embodiment, the electrodes on both sides of the piezoresistor chip 6 are connected to the first connection electrode 1 and the second connection electrode 2 respectively, and the piezoresistor chip 6 and the piezoresistor chip 6 are connected to the first connection electrode 1 and the second connection electrode 2 respectively. The junction of the connection electrode 2 is completely coated with an insulating coating 3 . The varistor chip is placed in the casing 4, and the inside of the casing 4 is filled with conductive particles 7, and the conductive particles 7 are closely attached to the insulating coating.

[0034] When the piezoresistor chip 6 begins to deteriorate, the heat ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com