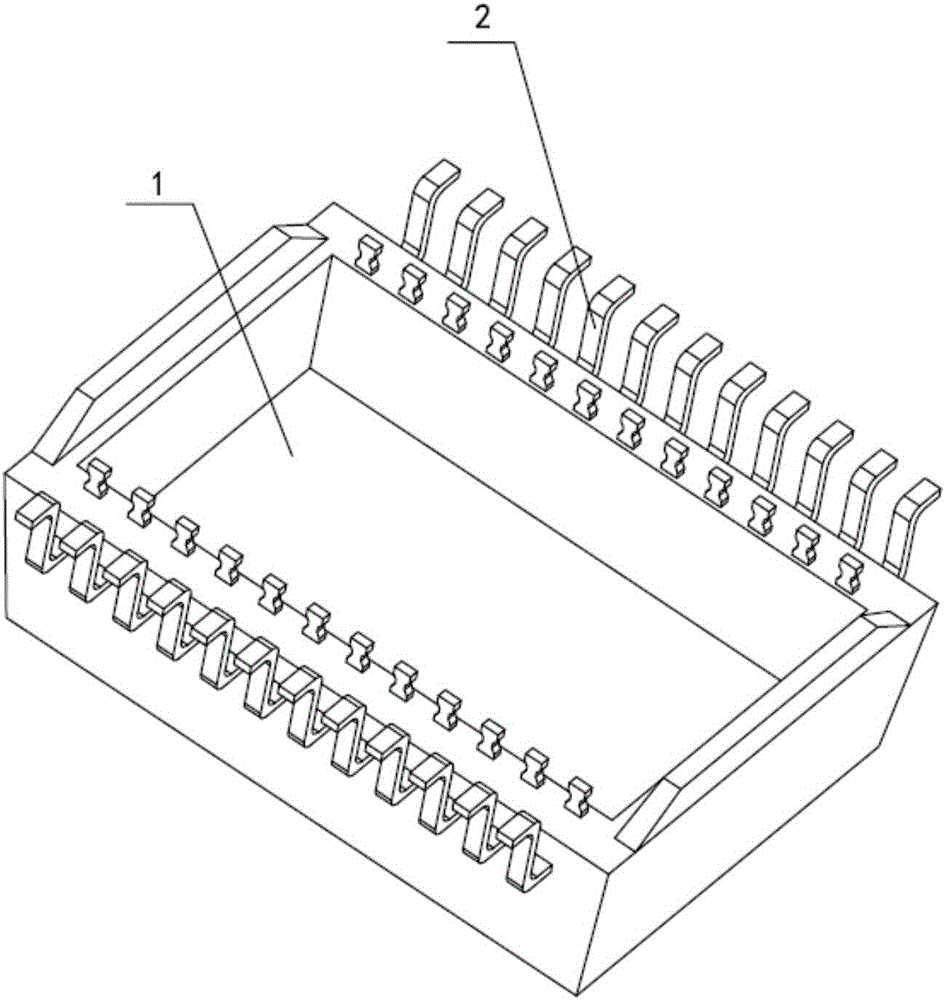

Network transformer shell, network transformer and manufacturing method thereof

A technology of network transformer and manufacturing method, applied in transformer/coil connector, transformer/inductor coil/winding/connection, transformer/inductor components, etc., can solve the problems of complex shell process and low efficiency, and achieve improved Electrical safety performance, production process reduction, effect of production process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

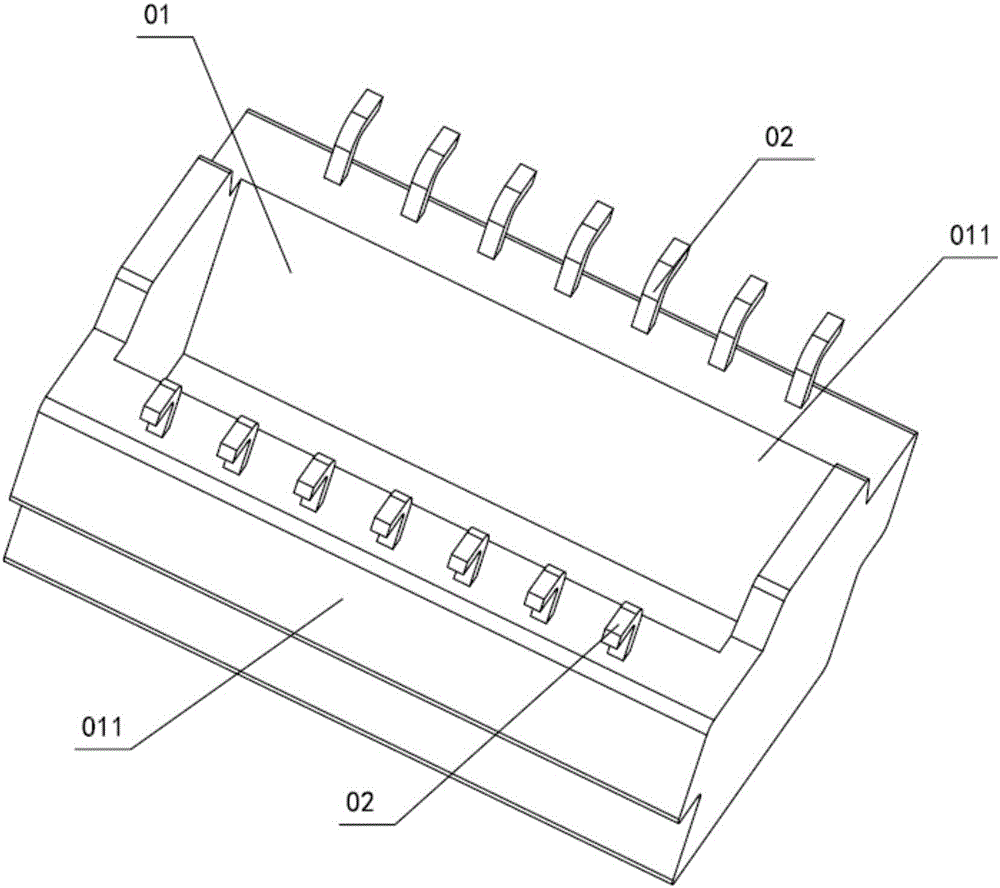

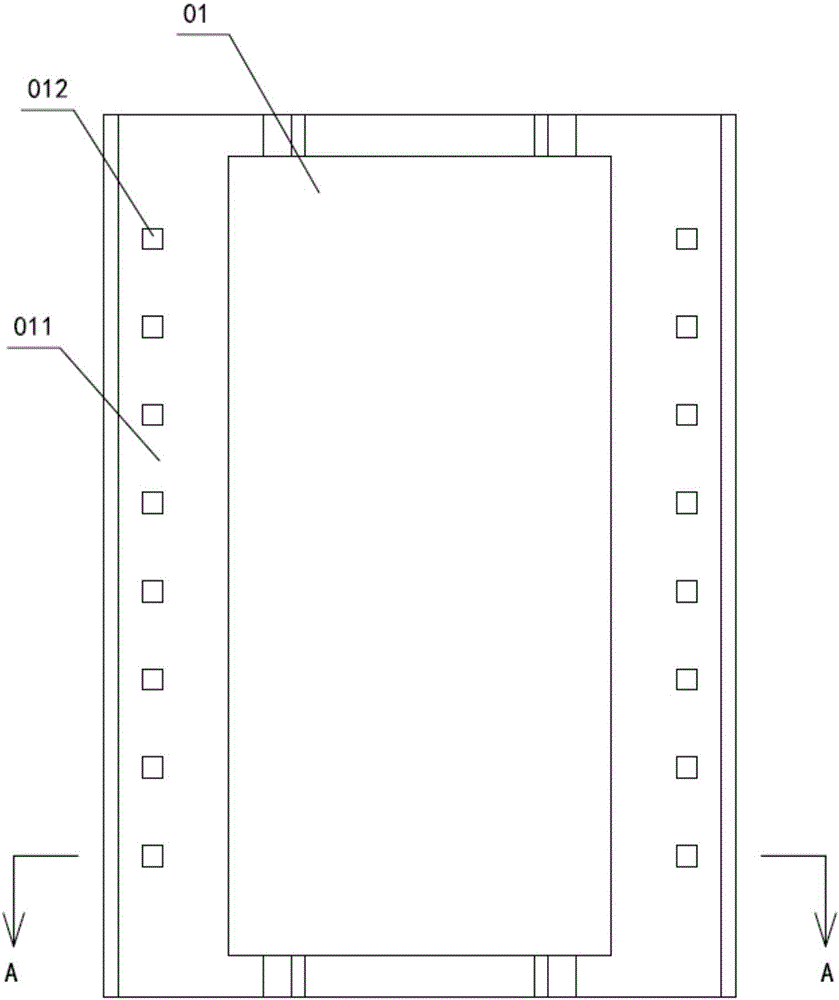

[0051] For the first direction view of the housing body in Embodiment 1, see image 3 , the network transformer shell, including a shell body 01 made of thermosetting flame-retardant material, the shell body 01 is in the shape of a box cover, the shell body 01 includes a shell side wall 011, and the shell side wall 011 is provided with a PIN pin on the end face of the opening Mounting hole 012.

[0052] image 3 For the cross-sectional view of A-A, see Figure 4 , the shell side wall 011 is provided with a PIN foot installation hole 012 on the end face of the opening; one end of the PIN foot 02 is inserted into the PIN foot installation hole 012, and the PIN foot 02 and the PIN foot installation hole 012 are an interference fit.

[0053] For the structural diagram of the PIN pin in Embodiment 1, see Figure 5 and Figure 6 , the part where the PIN pin 02 is inserted into the PIN pin mounting hole 012 is the PIN pin insertion section 021. There are two protruding side surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com