Electric heating cleaning method and device

An electric heating and cleaning technology, applied in the direction of electrode cleaning, cleaning methods and appliances, pump components, etc., to achieve the effect of wide application range, compact structure and high environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

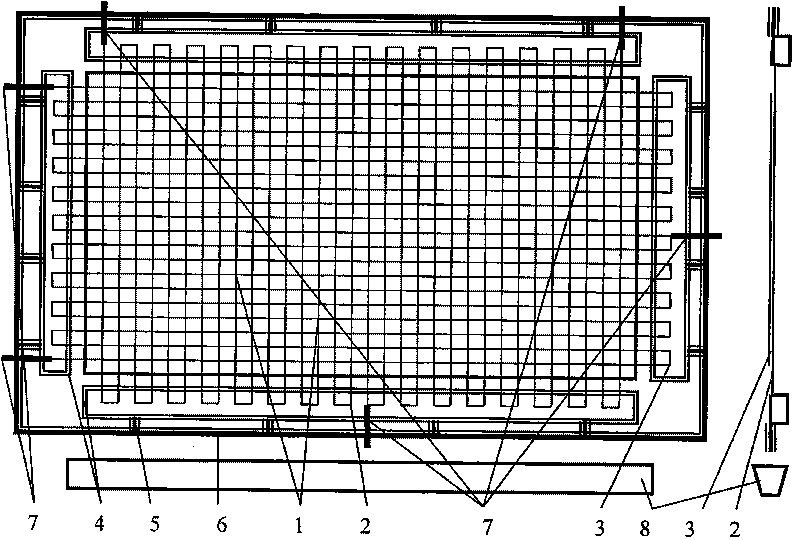

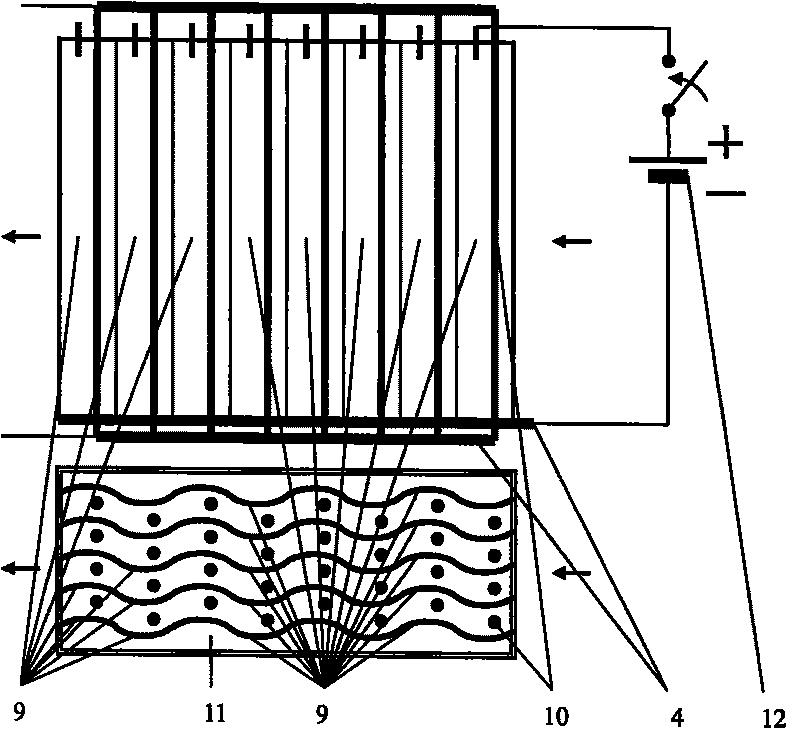

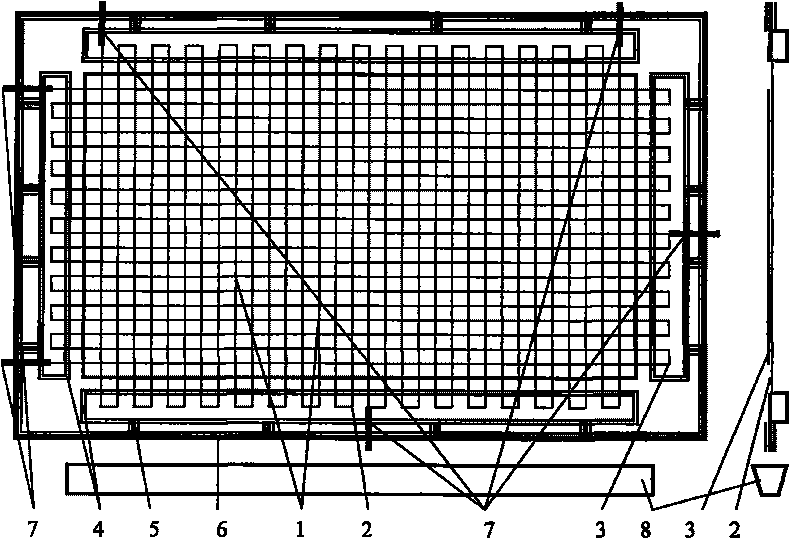

[0013] figure 1 In the embodiment, a non-intersecting woven filter screen 2 composed of a layer of vertically arranged filamentary electrothermal material 1 and a non-intersected woven filter screen 3 composed of a layer of horizontally arranged filamentary electrothermal material 1 are used to form an electrothermal cleaning filter device. The wires of non-cross-woven filter screens can be connected in series. The close arrangement of non-cross-woven filter screens 2 and 3 can not only reduce the number of electrical branches and switching devices without short-circuit phenomenon, but also obtain the filtering performance close to the cross-woven filter screen with warp and weft structure. The filamentary electric heating materials 1 constituting the non-cross-woven filter screens 2 and 3 hang on an electrical connector 4 with an insulating base, and the electrical connector 4 is connected to the frame 6 through a spring 5 . The spring 5 is used to absorb the end point disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com