Stripping device and stripping method adopting same

A peeling device and flexible substrate technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of flexible substrate deformation, damage to the performance of the active layer of the flexible substrate, defects, etc., and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

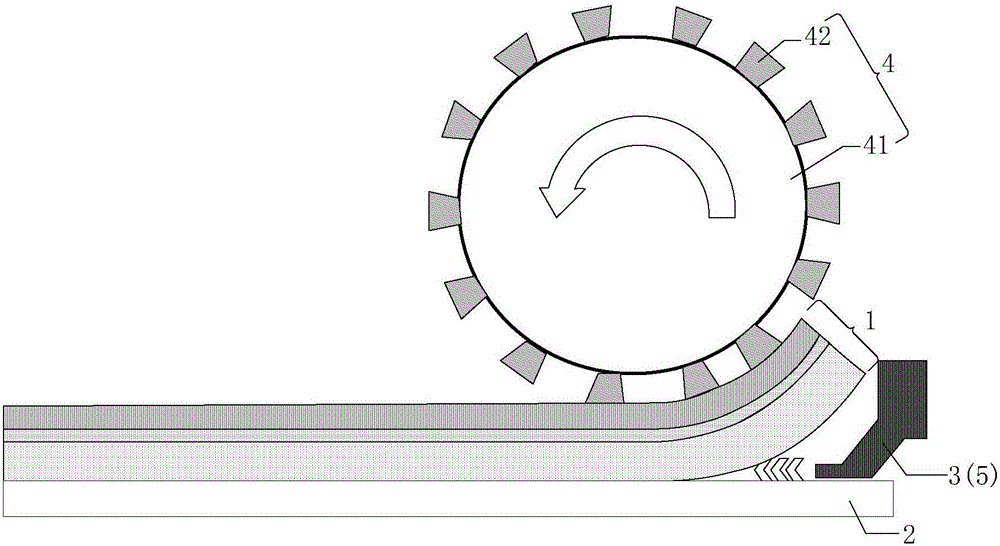

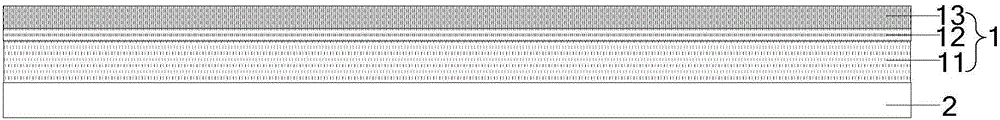

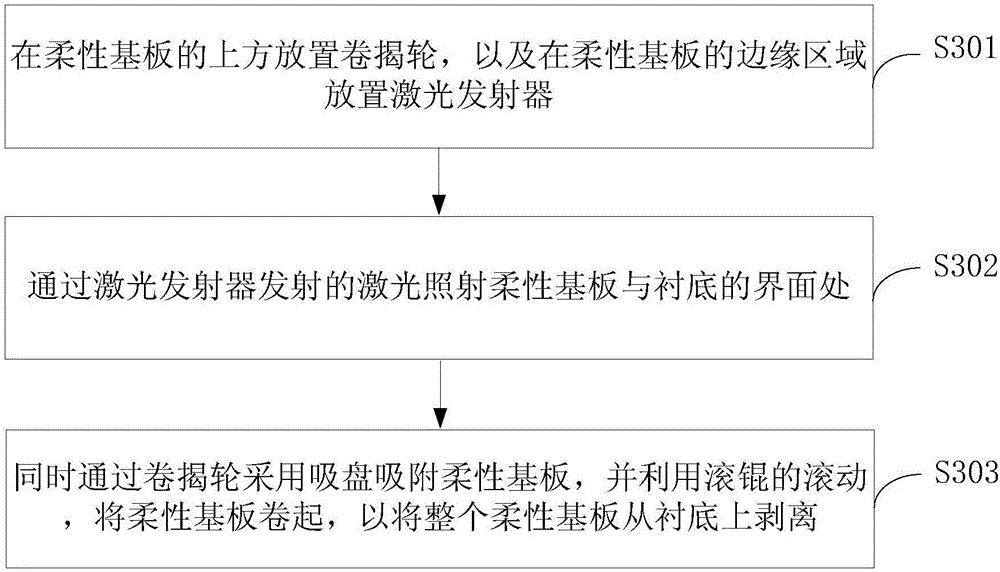

[0031] The specific implementation of the peeling device and the peeling method provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] Wherein, the size and shape of each structure in the drawings do not reflect the real scale of the peeling device, and the purpose is only to illustrate the content of the present invention.

[0033] Embodiments of the present invention provide a stripping device, such as figure 1 As shown, it is used to peel the flexible substrate 1 from the substrate 2, including: a laser emitter 3 and a roll-off wheel 4; the roll-off wheel 4 has a roller 41 and a plurality of suction cups 42 located on the roller 41;

[0034] A laser emitter 3, configured to emit laser light at the interface between the flexible substrate 1 and the substrate 2 at the edge region of the flexible substrate 1;

[0035] The rolling and unrolling wheel 4 is used to absorb the flexible substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com