Inspection robot positioning method and automatic charging method

A technology of inspection robot and positioning method, which is applied to instruments, current collectors, electric vehicles, etc., can solve problems such as high docking error requirements, and achieve the effects of good robustness, improved success rate, and fast and efficient charging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

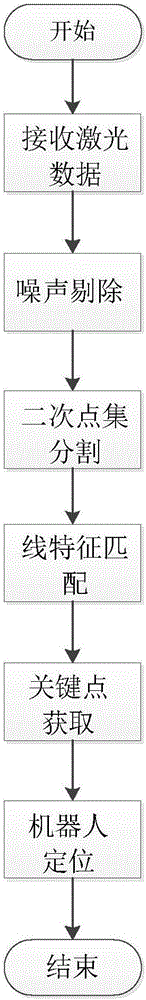

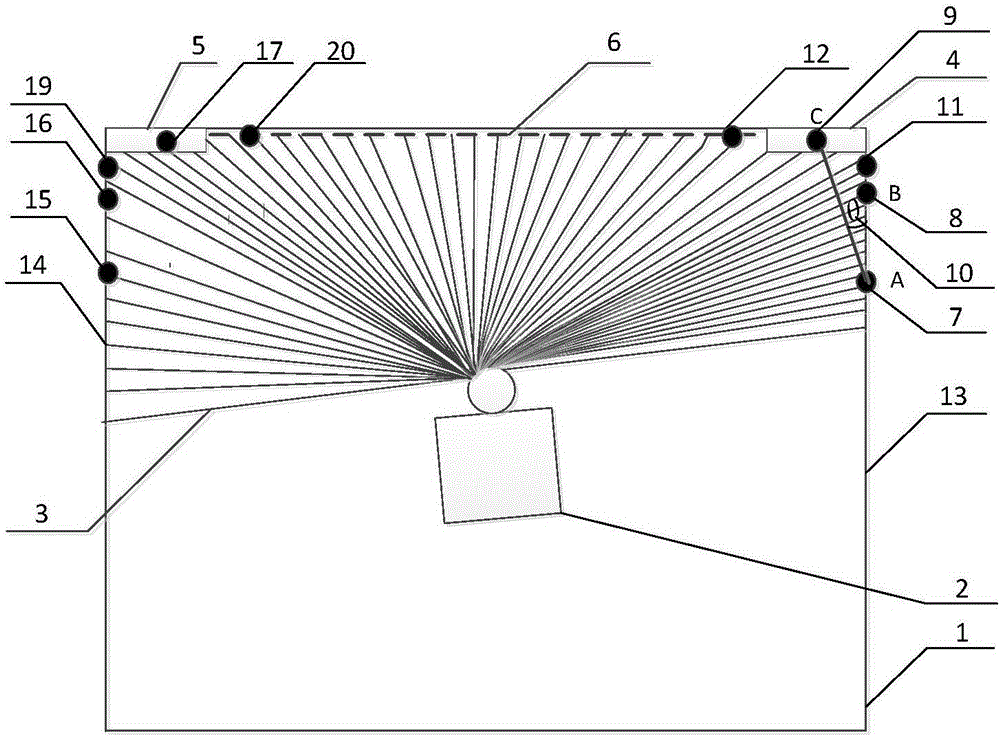

[0025] like figure 1 As shown, the main steps of the inspection robot positioning method provided by the present invention are as follows:

[0026] 1. Noise removal: De-noise the laser data collected by the laser sensor in front of the inspection robot 2 and on the walls on both sides of the charging room 1, remove the noise data, reduce the computational complexity and improve the accuracy;

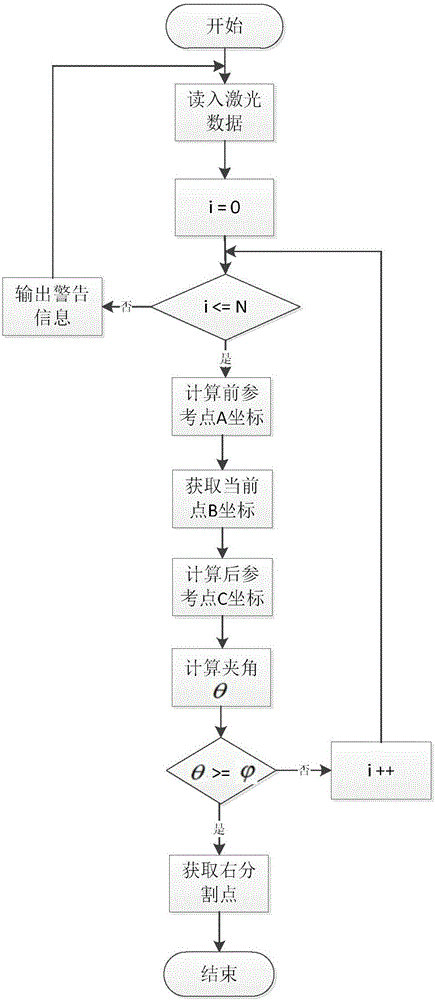

[0027] 2. Secondary point set segmentation: The laser acquisition data is divided into multiple continuous areas according to continuity. The principle of the quadratic point set segmentation algorithm is as follows figure 2 shown.

[0028] ①The first point set segmentation: Through smooth fitting, the accumulated error is amortized to improve the accuracy of segmentation.

[0029] The program flow chart of the first point set segmentation is as follows image 3 As shown, N represents the number of laser data, select continuous 2m+1 laser data (corresponding to the i-th to 2m+i-th l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com