Three-phase motor stator structure and motion

A stator structure, three-phase motor technology, applied in the direction of the motor, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve the problem that the motor torque requirements cannot be met, and the maximum torque requirements of the motor cannot be met. and other problems, to achieve the effect of small electromagnetic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

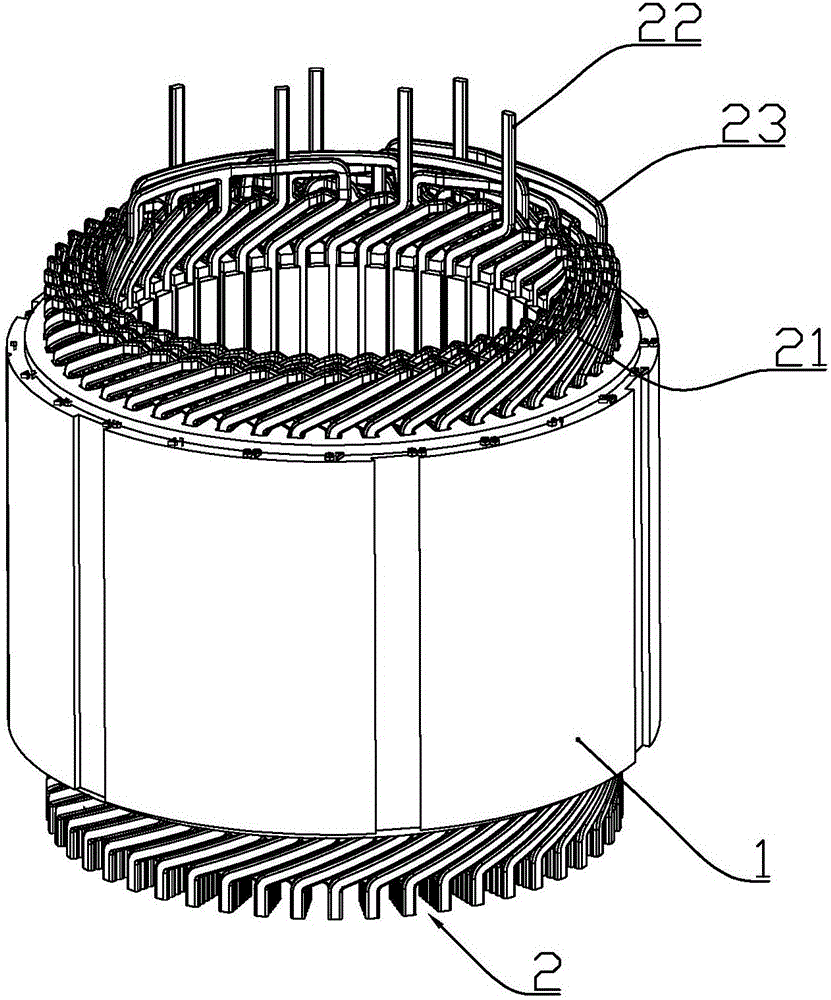

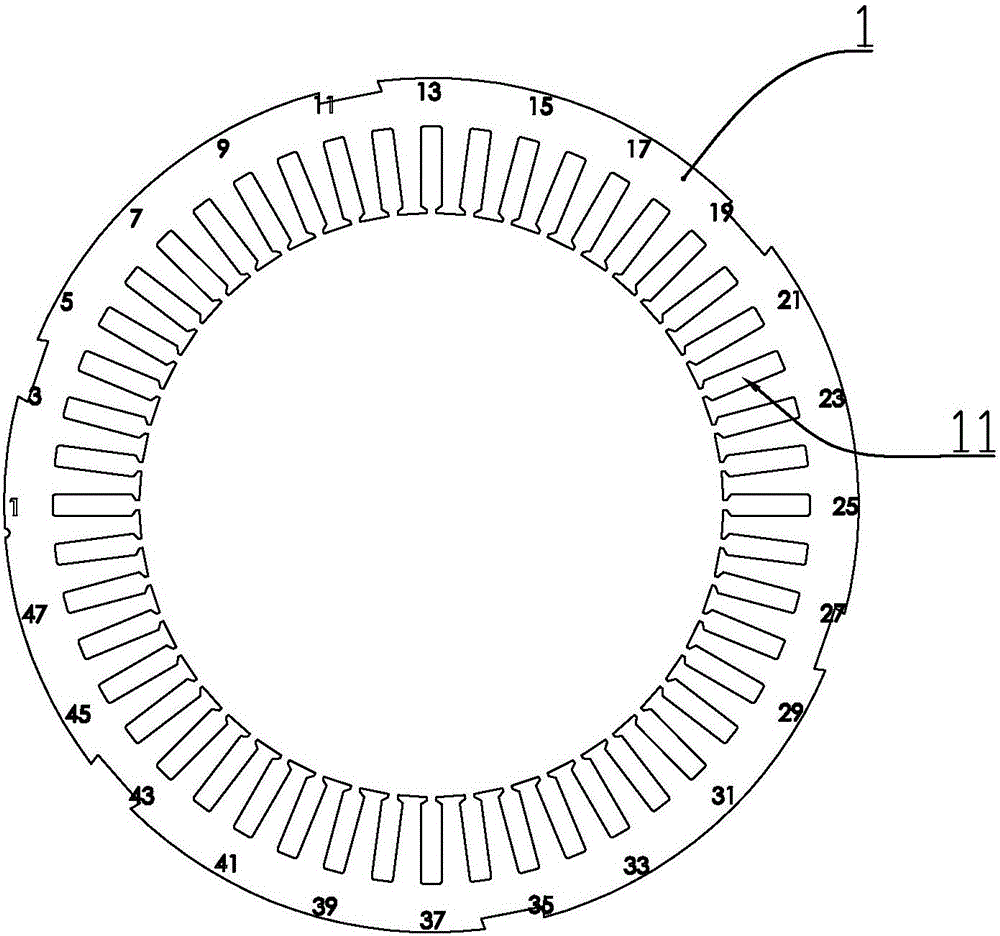

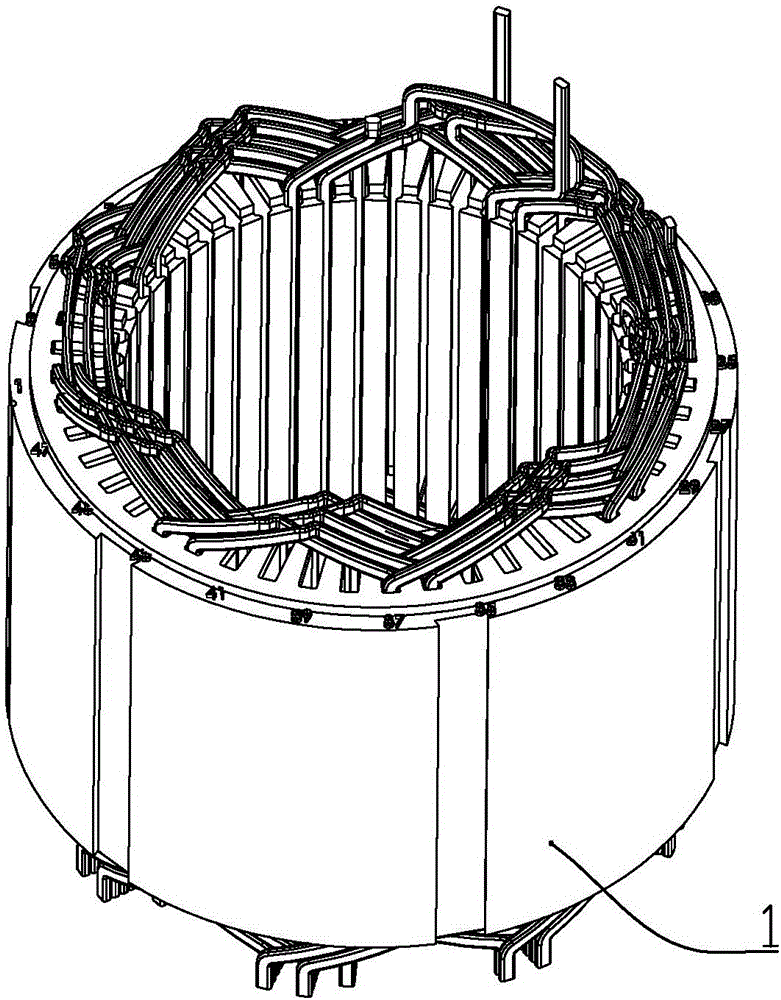

[0039] according to Figure 1 to Figure 12 As shown, this embodiment provides a stator structure of a three-phase motor, including an annular stator core 1 and a stator winding 2 installed on the stator core.

[0040] The inner wall of the stator core has a plurality of slots 11 equidistantly arranged along the circumference of the stator core for accommodating the stator windings, and the openings of each slot face the center of the stator core.

[0041] The stator winding includes two winding units connected in parallel, and each winding unit includes 3 branch windings connected in a star shape.

[0042] Each branch winding is composed of an outgoing wire 22 , multiple guide bars 21 and a neutral wire 23 connected in sequence.

[0043] The guide bar is composed of two pins 210 and a turning part integrally connected between the two pins, and the guide bar is connected to the adjacent guide bar or lead-out line or neutral line through the pins; the turning part It includes ...

Embodiment 2

[0060] This embodiment provides a three-phase motor, including the stator of Embodiment 1 and a rotor located on the inner periphery of the stator and coaxially arranged with the stator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com