Electric tail gate speed reduction motor used for automobile

A deceleration motor and deceleration mechanism technology, which is applied in the direction of electric components, power control mechanisms, electromechanical devices, etc., can solve the problems of large deceleration structure, accompanied by noise, large vibration, etc., and achieve compact structure, stable operation, and space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

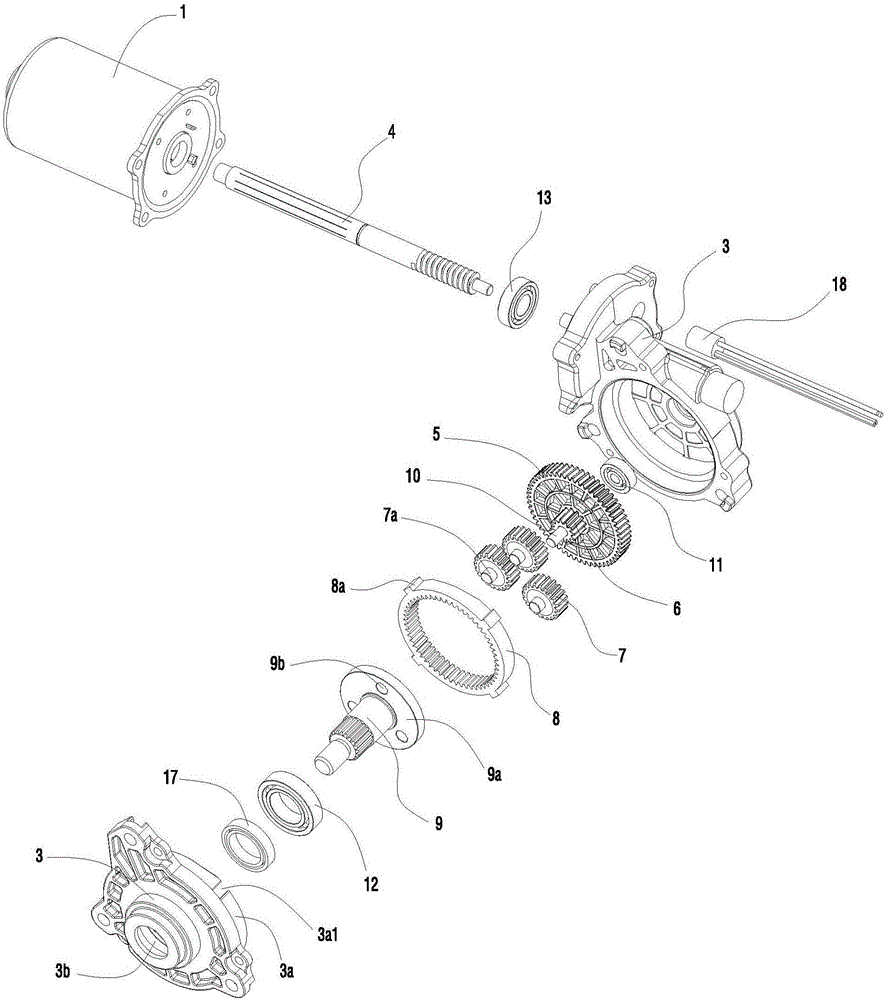

[0031] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

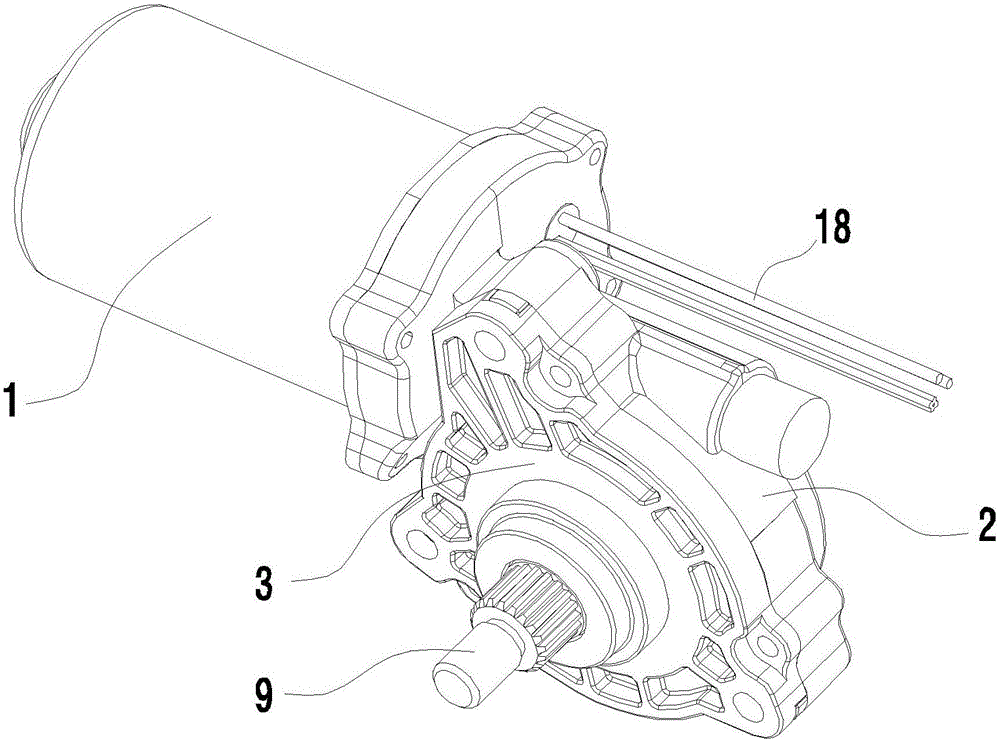

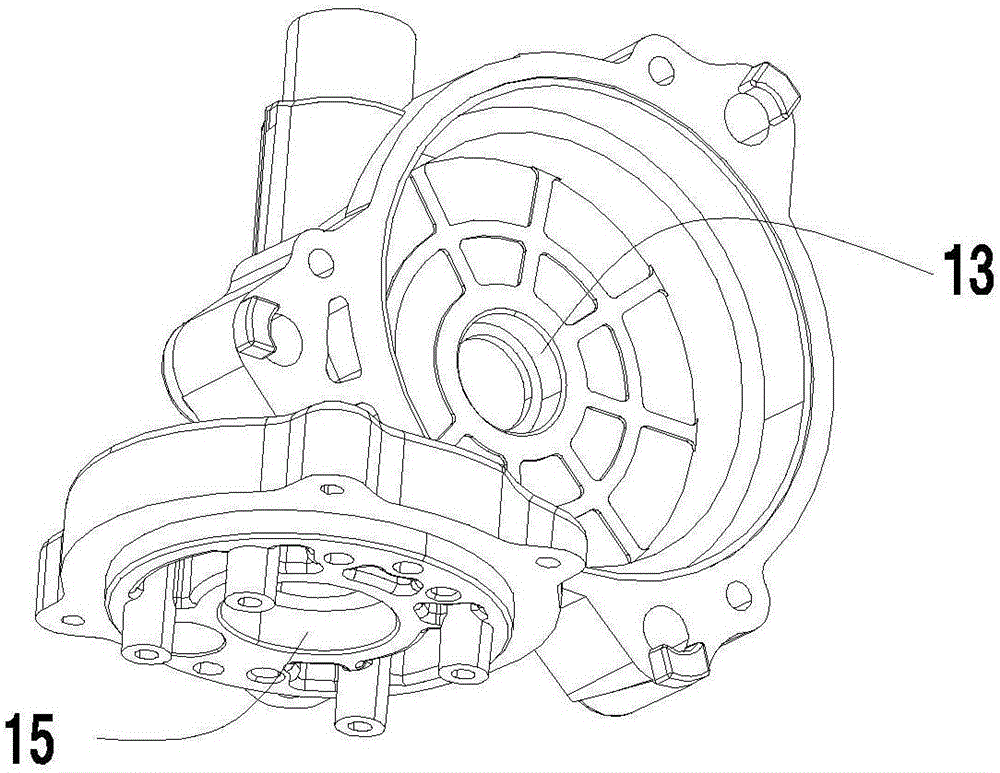

[0032] According to the illustrated embodiment of the present invention, there is provided an electric tailgate motor for automobiles, which includes a motor 1 and a reducer. A first-stage reduction mechanism and a second-stage reduction mechanism connected to the first-stage reduction mechanism;

[0033] The input shaft of the first-stage reduction mechanism is coaxial with the output shaft of the motor 1, and the output shaft of the first-stage reduction mechanism is perpendicular to the axis of the input shaft;

[0034] The input shaft of the secondary reduction mechanism is coaxial with the output shaft of the primary reduction mechanism, and the output shaft of the secondary reduction mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com