Automobile generator rotor assembly device

An automobile generator and rotor assembly technology, applied in the field of machine tools, can solve the problems of easy skew, poor safety, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

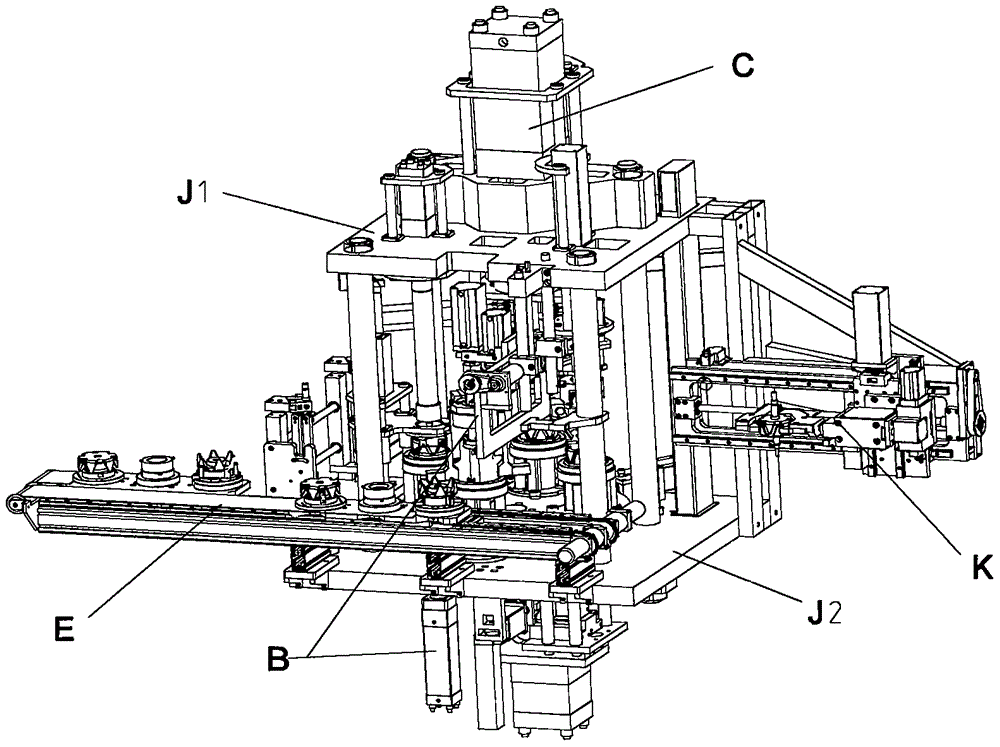

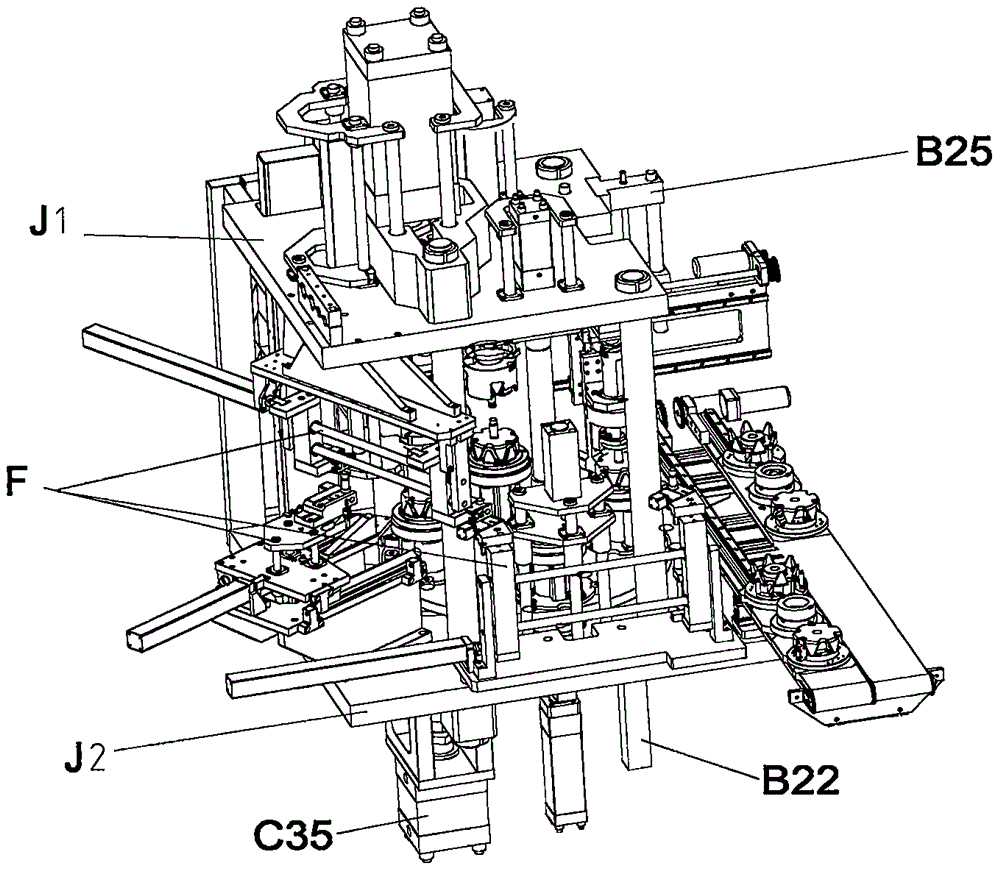

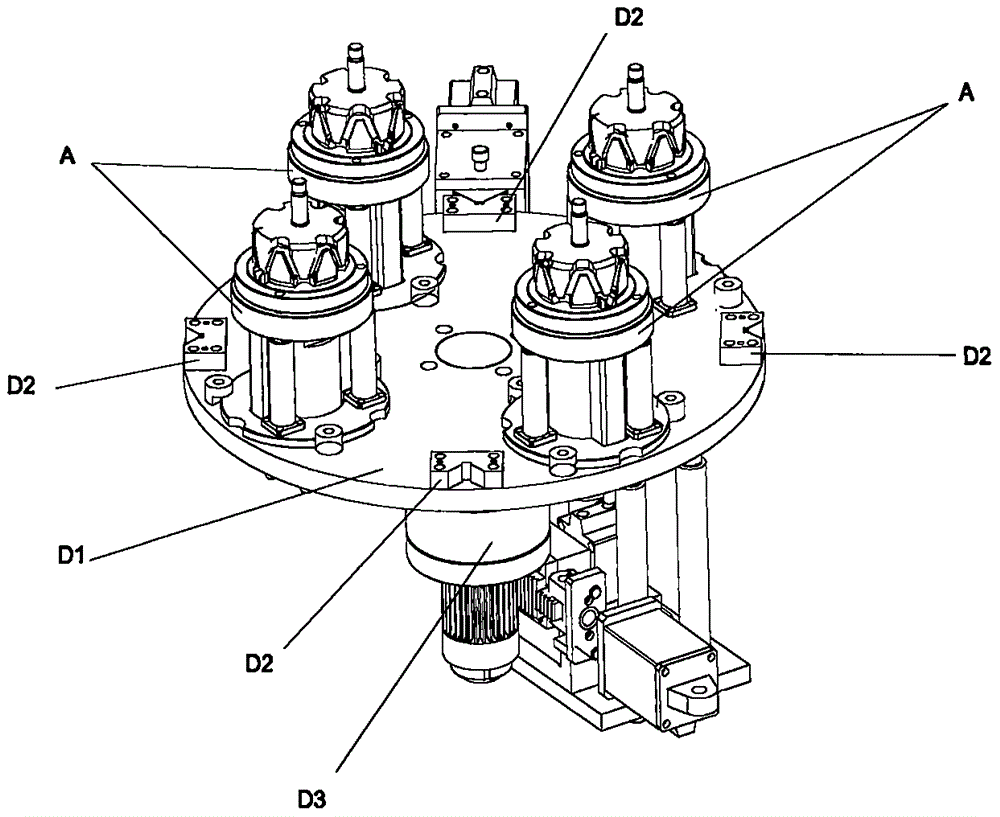

[0059] refer to Figure 1 to Figure 15 , an automobile generator rotor assembly equipment, including an automobile generator rotor, the automobile generator rotor is vertically arranged, including a lower claw pole with claws facing upwards, a coil, an upper claw pole with claws facing downwards, and a rotor shaft, the The coil is located between the upper claw pole and the lower claw pole, the upper claw pole and the lower claw pole are closed and matched, and the rotor shaft passes through the upper claw pole, the coil and the lower claw pole in turn from top to bottom, so The rotor assembly equipment includes a frame and a workpiece conveying mechanism E arranged on the frame to convey the upper claw pole, coil and lower claw pole, a material grabbing mechanism B for grabbing workpieces, an indexing rotary table D, The closing mechanism for closing the upper claw p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com