Novel two-stage multi-level power inversion system

A multi-level inverter and power inverter technology, which is applied in the direction of converting DC power input to DC power output, converting AC power input to DC power output, and adjusting electrical variables, etc., which can solve the problem of reducing system reliability and increasing DC power. Power supply output ripple, large current harmonics and other issues, to achieve the effect of excellent control quality, small system work efficiency, and small current harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

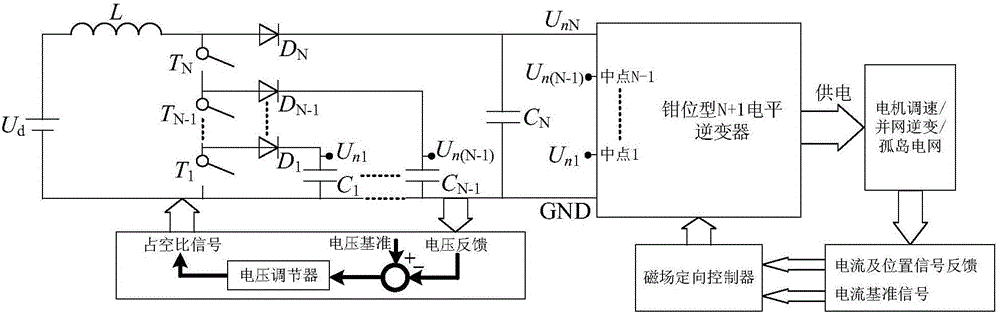

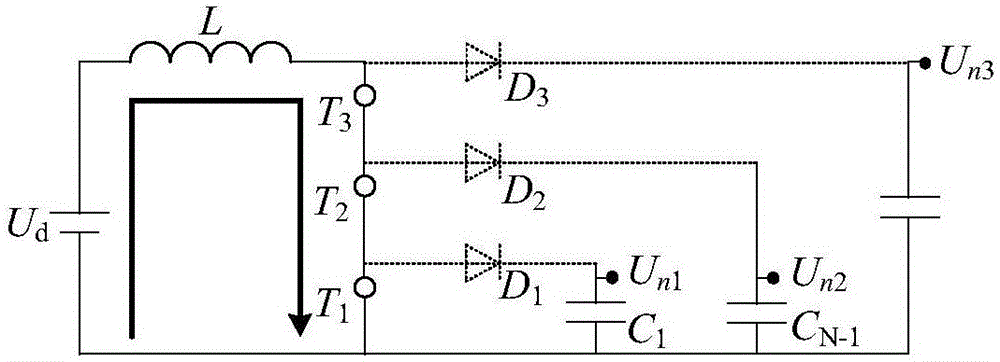

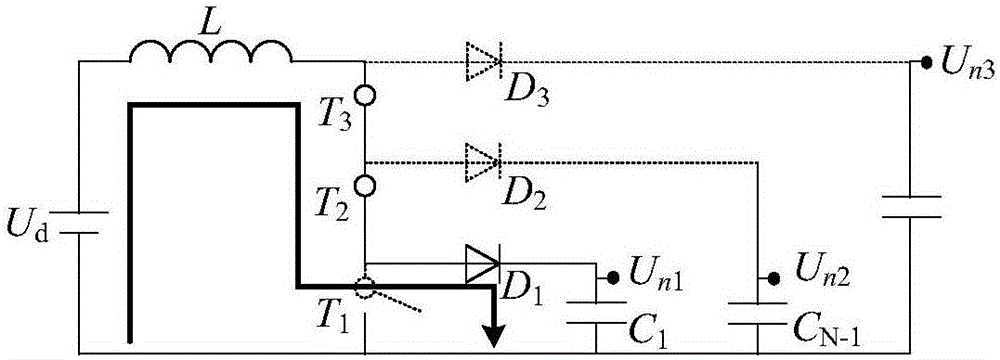

[0030] The present invention is a novel two-stage multi-level power inverter system, such as figure 1 As shown, a front-stage multi-output DC-DC converter and a diode clamped multi-level inverter are cascaded as the power topology. Through the voltage closed-loop control of the front-stage DC-DC converter, the power supply boost and the active control of the midpoint voltage of the multi-level inverter are realized. The latter-stage clamped multi-level inverter can realize motor drive and grid-connected inversion. Change, or island grid operation.

[0031] The invention discloses a novel two-stage multi-level power inverter system, which includes a front-stage multi-output DC-DC converter, a back-stage multi-level inverter and a load end. The front-stage multi-output DC-DC converter and the rear-stage multi-level inverter are independentl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com