Observer-based electric vehicle permanent magnet synchronous motor system error compensation control method

A permanent magnet synchronous motor, compensation control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve the problems of performance degradation, high cost, calculation explosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

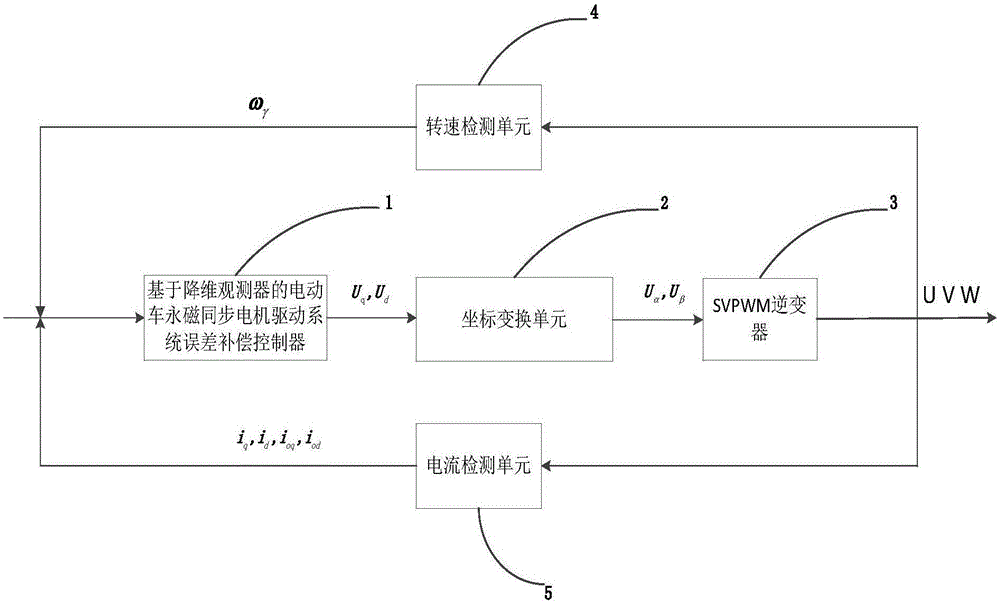

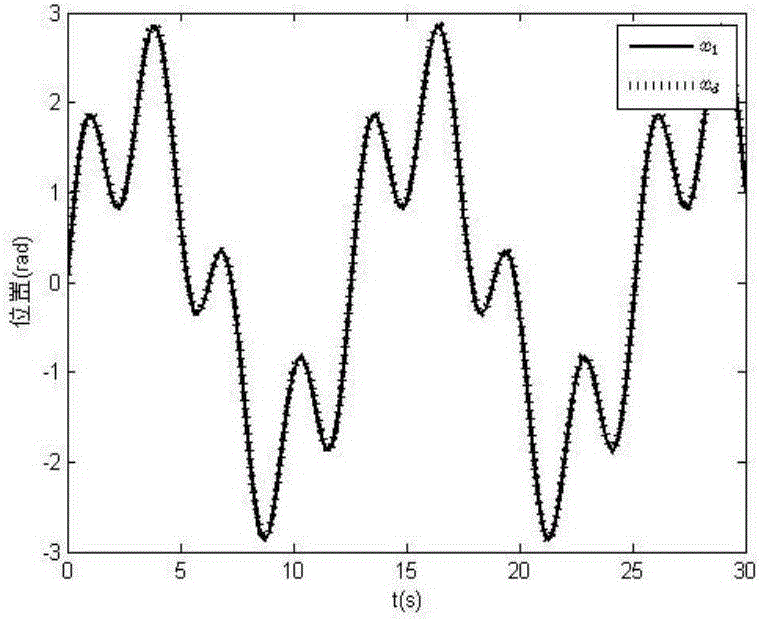

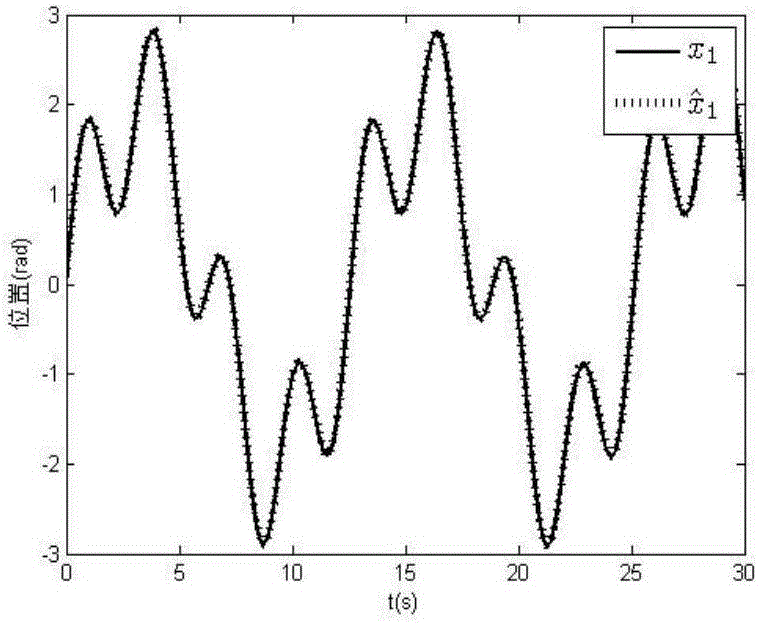

[0125] The basic idea of the present invention is: use the reduced-dimensional observer to estimate the rotor angular velocity of the permanent magnet synchronous motor, and at the same time use the fuzzy logic system to approximate the highly nonlinear function in the system, and combine the self-adaptive and backstepping technology to construct the controller, and the command filtering technology Introduced into the selection of the Lyapunov function in the recursive process and the construction of the intermediate virtual control signal, the control law is obtained by recursion, and the corresponding adaptive law is designed to adjust the unknown parameters; the command filter technology is introduced, without differential operation, The derivative signal of the command signal can be generated, which reduces the amount of calculation and sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com