A rail connection block

A technology of connecting blocks and guide rails, applied in photovoltaic modules, supporting structures of photovoltaic modules, electrical components, etc., can solve the problems of inability to ensure electrical continuity, cumbersome operation, poor aesthetics, etc., to improve aesthetics and cleanliness, operation. The effect of convenient and reliable electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

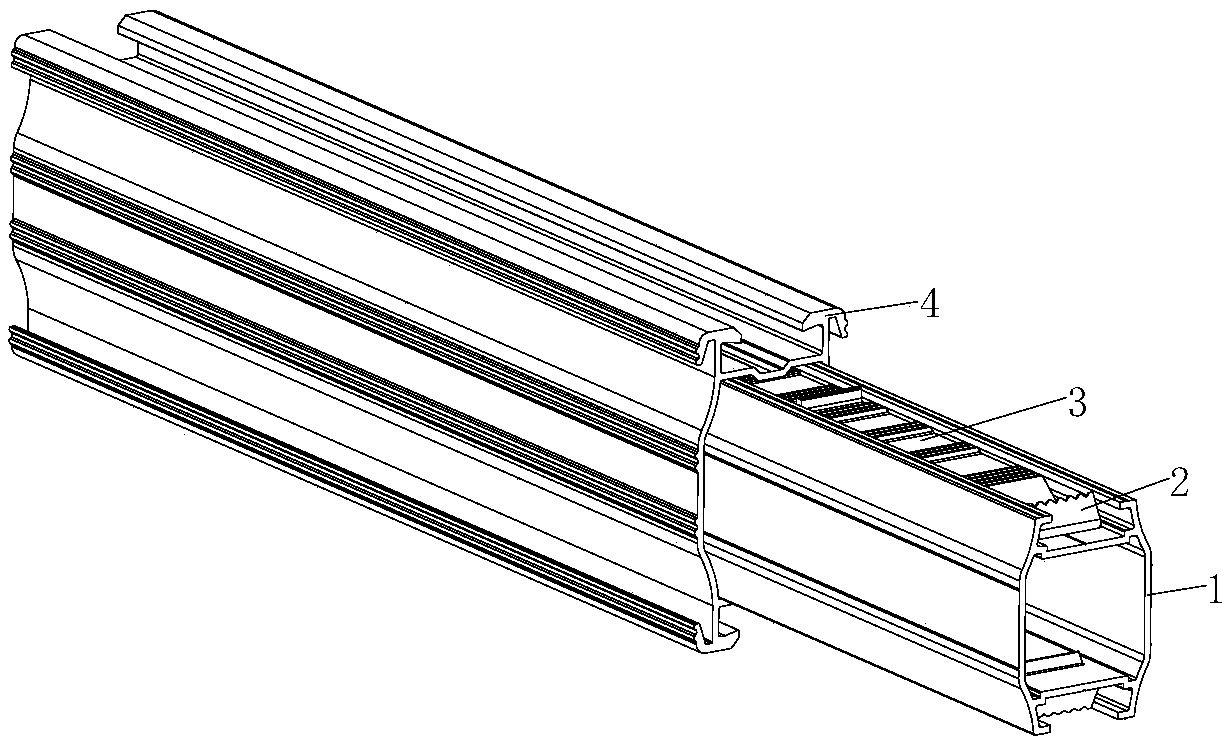

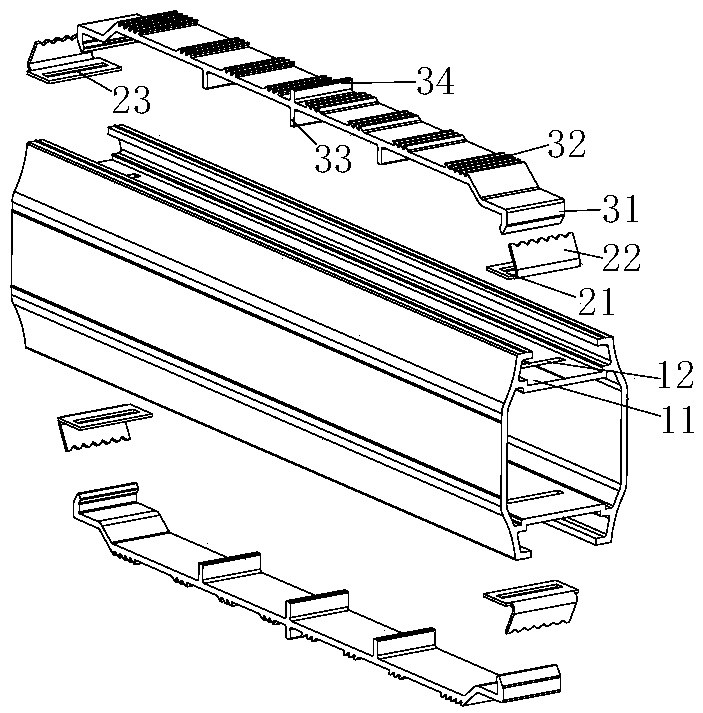

[0024] like figure 1 and figure 2 As shown, a guide rail connection block is used for connection between fixed guide rails of solar panels, and is composed of a body 1 , a clamping piece 2 and a clamping piece 3 .

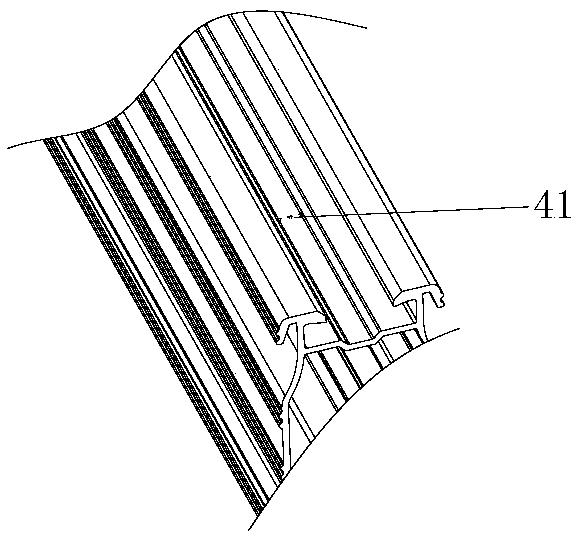

[0025] Wherein, the outer contour of the body 1 fits with the inner cavity of the guide rail 4 to be connected so as to be inserted into the inner cavity of the guide rail 4 . The upper end of the body 1 is provided with a longitudinal groove 11 consistent with the direction of the guide rail 4, and a button hole 12 is provided at the bottom of the groove at both ends of the longitudinal groove 11. In this embodiment, the shape of the button hole 12 is a square perpendicular to the longitudinal groove 11. Long holes.

[0026] There are two clamping pieces 2, which are symmetrically placed on the left and right sides of the longitudinal groove 11. The clamping piece 2 is a metal sheet with a straight section 21 and an upwardly folded section 22, and the hardness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com