Overall lattice reflection weighted surface acoustic wave resonator

A surface acoustic wave and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of not mentioning, not considering the first type of side peaks, and not suppressing the first type of side peaks, so as to reduce side peak interference. , the effect of improving the frequency response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

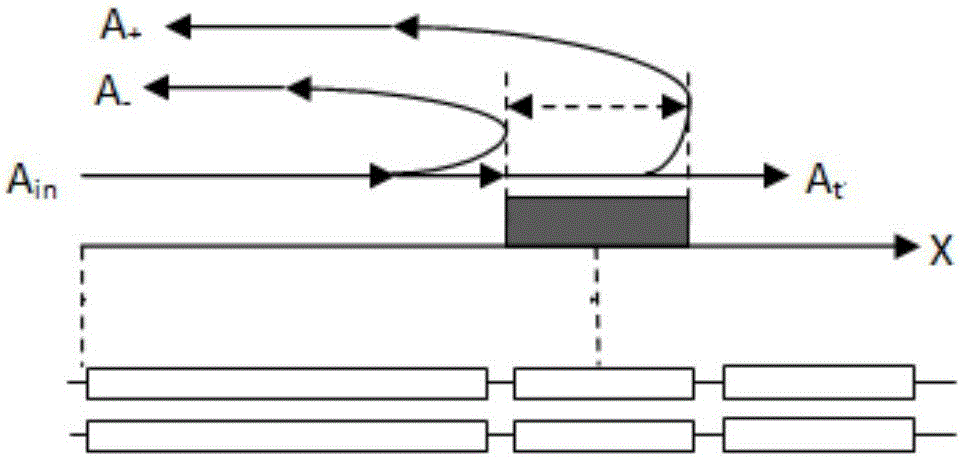

Problems solved by technology

Method used

Image

Examples

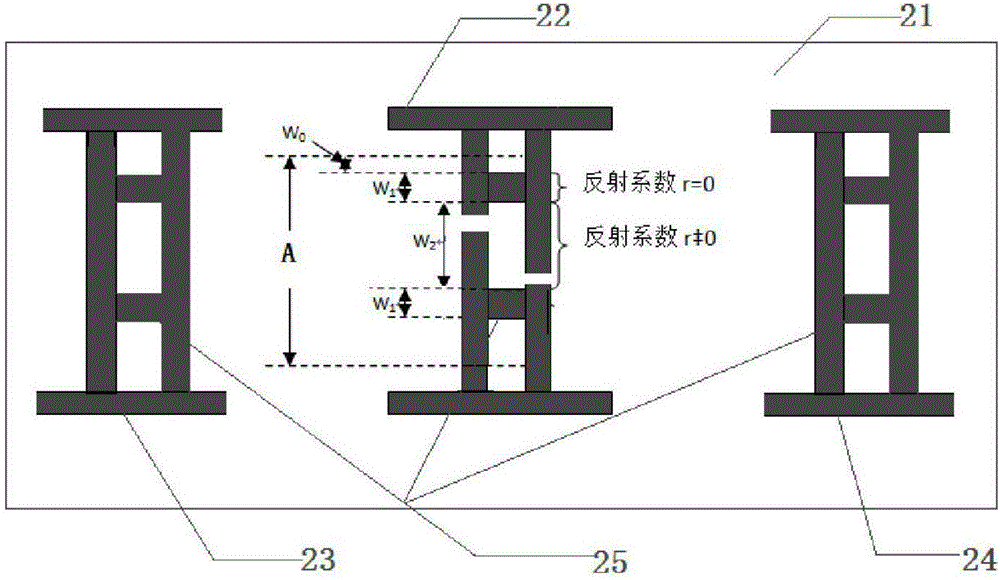

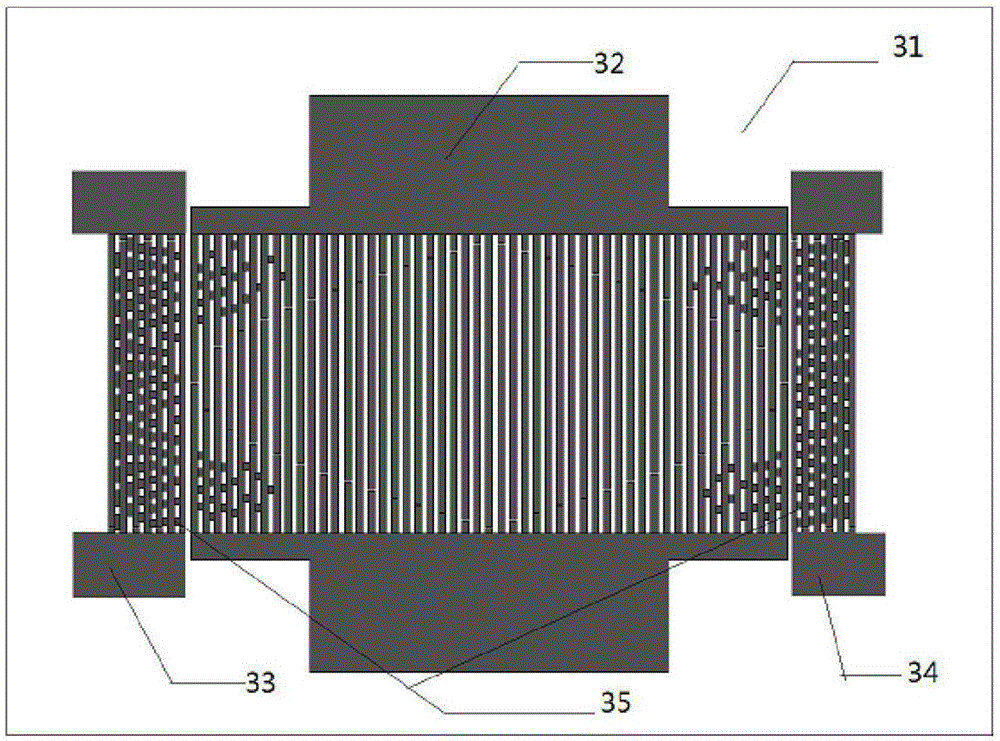

Embodiment approach 1

[0045] The piezoelectric substrate 31 adopts ST-X quartz; the IDT dummy finger and the metal lattice on the reflective grid are weighted by Hamming function. Specifically, the SAW resonator structure after Hamming function lattice weighting is simulated by software to obtain the S11 parameters of the SAW resonator, such as Figure 5 shown. Compared with the S11 parameters of the SAW resonator without metal lattice weighting, the side peaks are reduced from 0.15 to about 0.03.

Embodiment approach 2

[0047] The piezoelectric substrate 31 adopts ST-X quartz; the metal lattice on the IDT dummy finger and the reflective grid is weighted by an arccosine function. Specifically, the SAW resonator structure after the arccosine function lattice weighting is simulated by software to obtain the S11 parameters of the SAW resonator, such as Figure 6 shown. Compared with the S11 parameters of the SAW resonator without metal lattice weighting, the side peaks are reduced from 0.15 to about 0.035.

Embodiment approach 3

[0049] The piezoelectric substrate 31 adopts ST-X quartz; the IDT dummy finger and the metal lattice on the reflection grid are weighted by Kaiser (beta=3.2) function. The specific Kaiser function and the structure of the SAW resonator after lattice weighting are simulated by software to obtain the S11 parameters of the SAW resonator, such as Figure 7 shown. Compared with the S11 parameters of the SAW resonator without metal lattice weighting, the side peaks are reduced from 0.15 to about 0.003.

[0050] Through the comparison of the above three embodiments, it can be seen that by performing lattice weighting on the IDT dummy finger and the reflection grid at the same time, the side peaks formed by the acoustic wave reflection can be controlled, the out-of-band suppression can be improved, and the frequency response performance of the SAW resonator can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com