Surveillance camera device

A technology for monitoring cameras and equipment, applied in mechanical equipment, image communication, television, etc., can solve the problems of affecting the stability of normal work, cumbersome disassembly and assembly process, time-consuming and labor-intensive efficiency, etc., to facilitate repeated installation and use, and improve safety. Sex, the effect of preventing electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

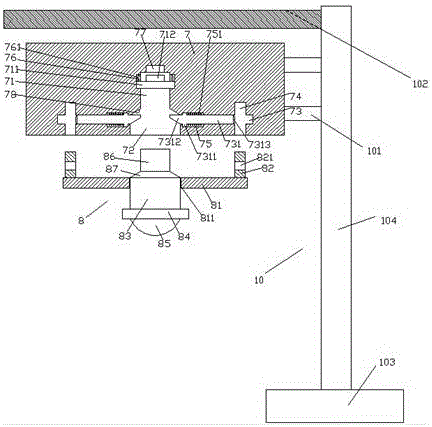

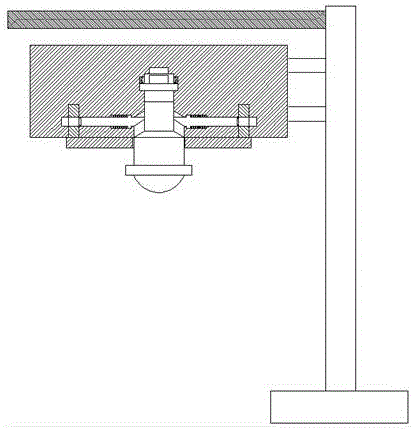

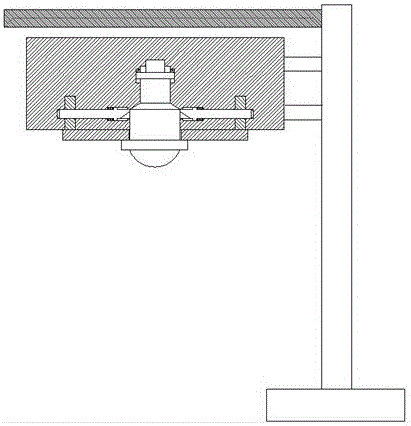

[0021] Such as Figure 1-Figure 4 As shown, a monitoring camera device of the present invention includes a fixed base 7 and a monitoring component 8 used to cooperate with the fixed base 7 and a support component 10 arranged on the right side of the fixed base 7. A first sliding groove 71 is provided at the inner center of the seat 7, a second sliding groove 72 is provided below the bottom end of the first sliding groove 71, and the inner top wall of the fixed seat 7 above the upper end of the first sliding groove 71 A power transmission cavity 77 is provided, and the inner wall of the fixing seat 7 on both sides of the first sliding groove 71 is provided with a first sliding groove 76, and a pushing block 711 is slidingly fitted in the first sliding groove 76, and the The upper end of the pushing block 711 is provided with a power transmission column 712 corresponding to the power transmission chamber 77, and the upper end of the pushing block 711 in the first sliding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com