Apparatus and method for repairing display using conductive ink

A conductive ink and display technology, which is applied in electrostatic spraying devices, spraying devices, identification devices, etc., can solve the problems of conductive inks that are difficult to repair, precise repair of difficult opening defects, and difficult repair of opening defects, and achieve the effect of avoiding the phenomenon of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings. However, in the process of describing the embodiments, if it is judged that the detailed description of related well-known functions or components may unnecessarily obscure the gist of the present invention, the detailed description will be omitted. In addition, the size of each component in the drawings may be exaggerated for convenience of description, but this does not mean the actual size.

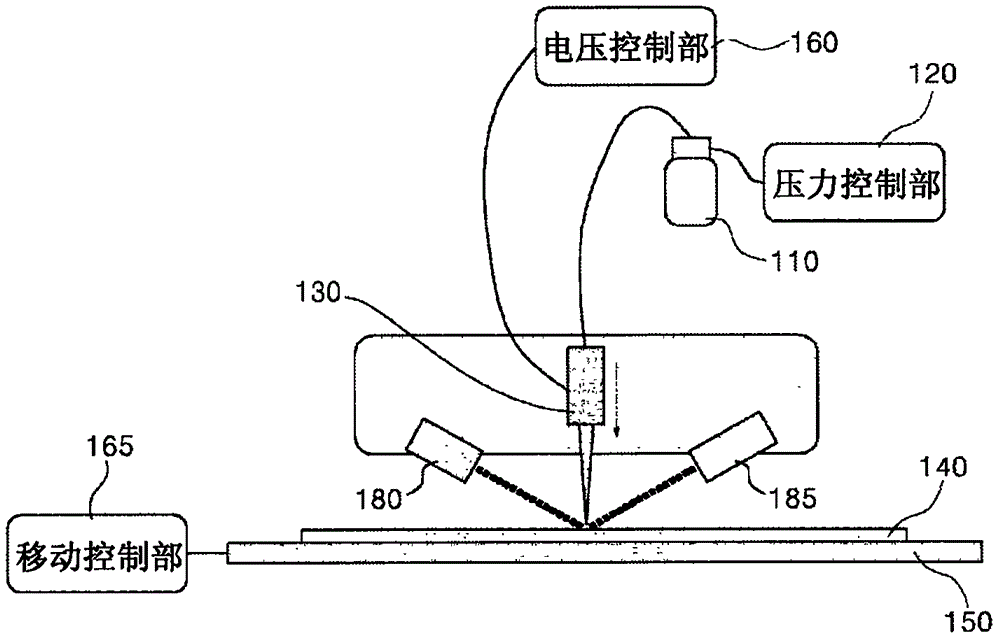

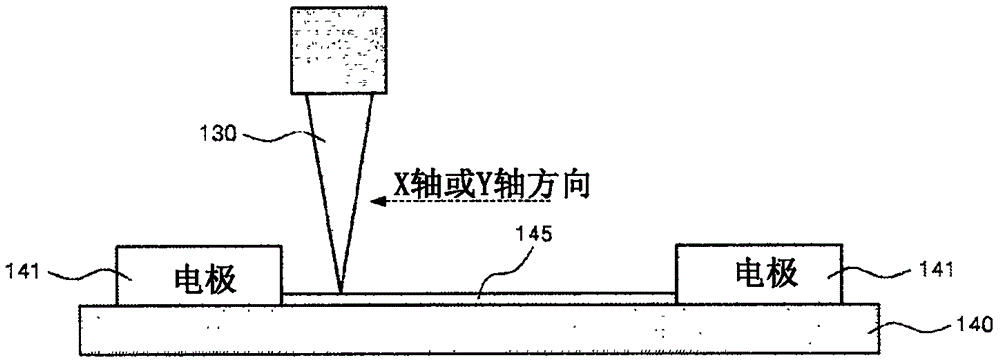

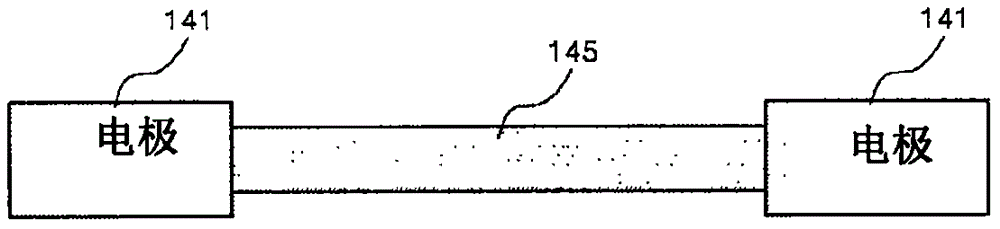

[0032] figure 1 Shown is a schematic diagram illustrating a display repair device using conductive ink in an embodiment of the present invention.

[0033] refer to figure 1 , a display repair device using conductive ink in an embodiment of the present invention will be described.

[0034] Such as figure 1 As shown, the display repair device using conductive ink in an embodiment of the present invention comprises: a pressure control unit (120), a nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com