An apparatus to print on water-soluble film

A technology of water-soluble film and equipment, applied in the field of equipment for printing on water-soluble film, to achieve the effect of space efficiency, constant tension or elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] equipment

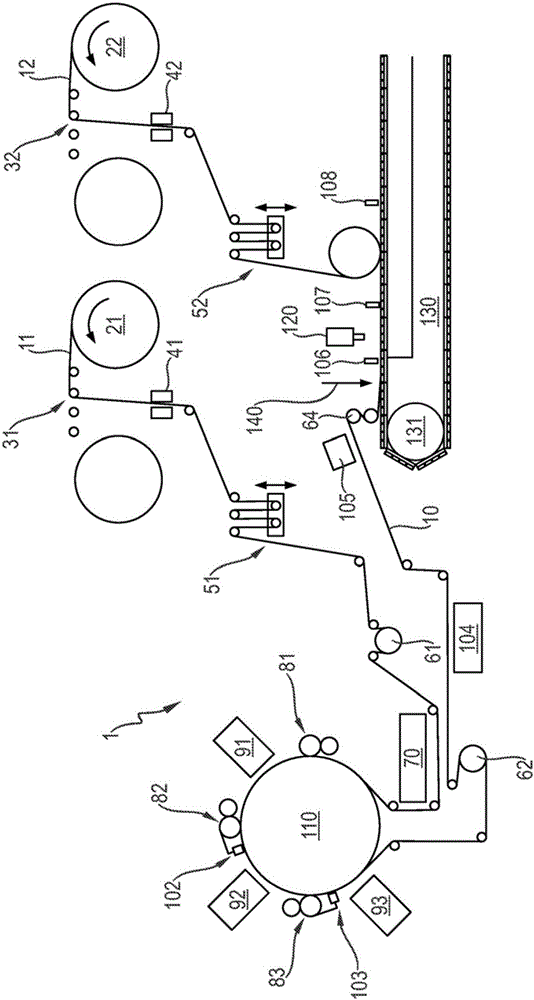

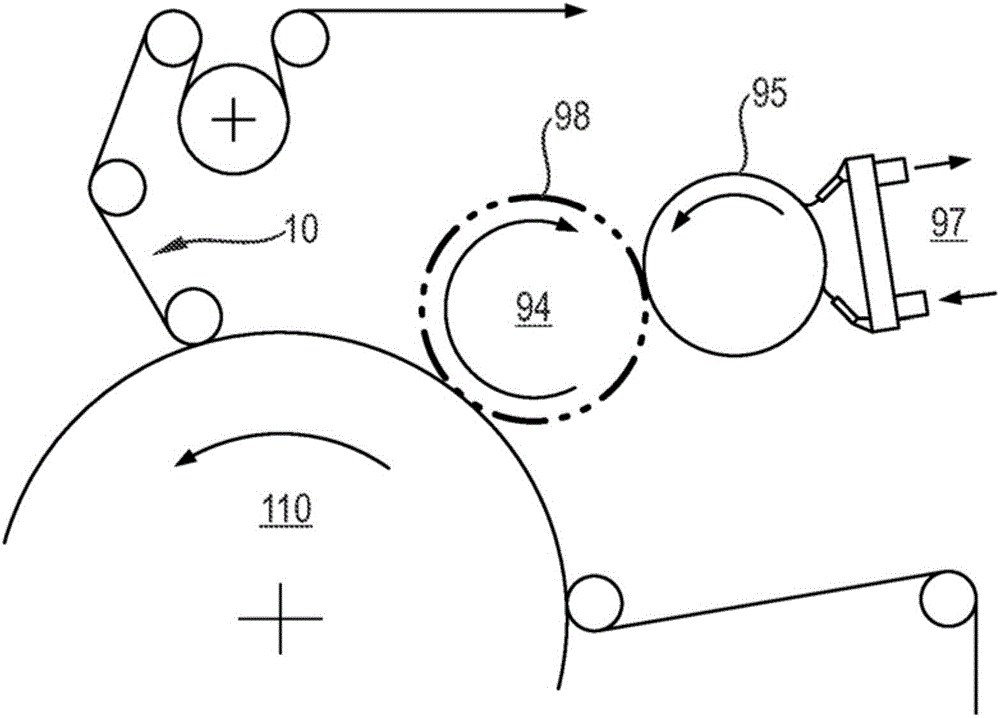

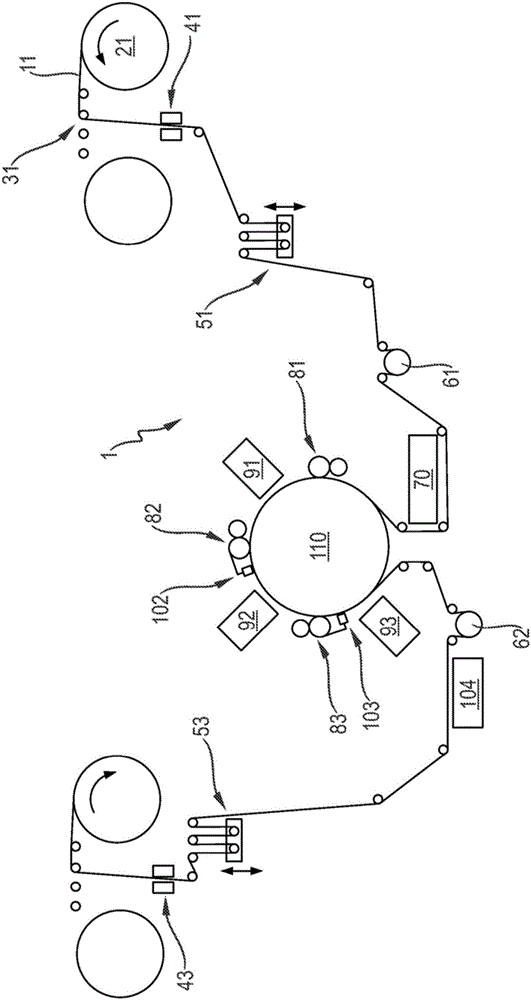

[0014] Such as figure 1 As shown, the apparatus 1 comprises a roll 21 of the film to be printed. The film 11 contains polyvinyl alcohol or a copolymer thereof. The film can be unwound from a spindle or a reel. The apparatus may comprise a film unwinder 31 . The equipment may include an automatic splicer 41 . The device may include an accumulator / regulation system 51 for controlling the tension and speed of unwinding. Tension and metering speed can be controlled by using a feed drive roller 61 to feed the printing unit, which may or may not be coupled to a tension measuring load cell in the control loop. The apparatus may include a membrane pretreatment station 70 . A film pre-treatment station may provide corona treatment for improving spreadability and / or deposition of compounds to be printed (eg, dyes or inks). The apparatus includes a rotating drum 110 . The apparatus comprises a printing system 80 for printing on the film. The printing system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com