High-strength steel material for oil wells, and oil well pipe

A high-strength, well-oiled technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as low strength and rising manufacturing costs, and achieve high yield strength and excellent SSC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

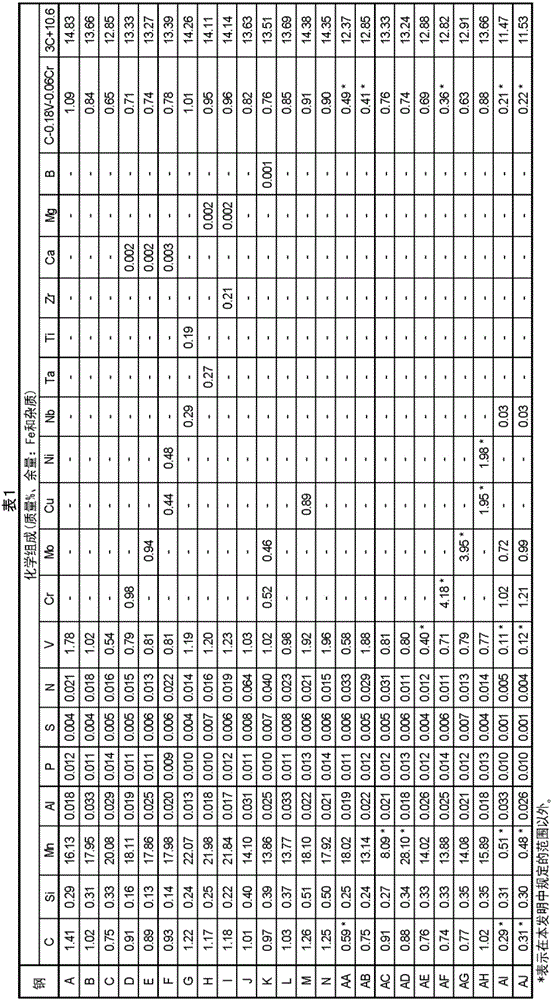

[0158] Twenty-two kinds of steels A to N and AA to AH having the chemical compositions shown in Table 1 were melted in a 50 kg vacuum furnace and cast into ingots. Each ingot was heated at 1180° C. for 3 hours, then forged, and broken by electric discharge cutting. Then, soak at 1150° C. for 1 hour, and hot-roll to form a plate with a thickness of 20 mm. Furthermore, solution heat treatment was performed at 1100° C. for 1 hour (water cooling after heat treatment), and then age hardening treatment was performed at the heating temperature and holding time shown in Table 2 to obtain test materials.

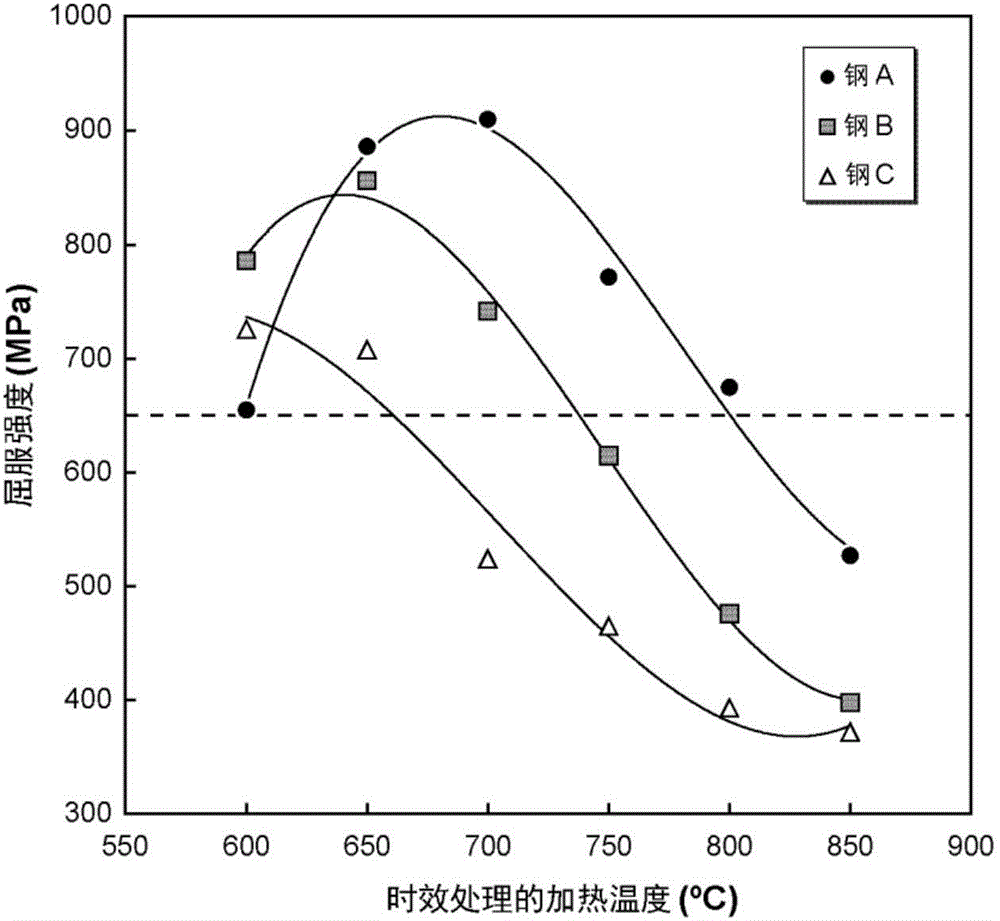

[0159] It should be noted that, for Steels A to C, different from the heat treatment conditions shown in Table 2, a plurality of samples were prepared for the purpose of studying the relationship between the heating temperature for aging treatment and the yield strength. Aging treatment is carried out under various temperature conditions. The holding time for the aging treatment ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com