Heating body for electrically heatable glow plug with axially pressed heating insert and associated production method

A technology of heating body and glow plug, which is applied in the direction of heating element shape, combustion method, electric heating device, etc., and can solve problems such as deterioration of electrical properties, deterioration of function and quality of glow plugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

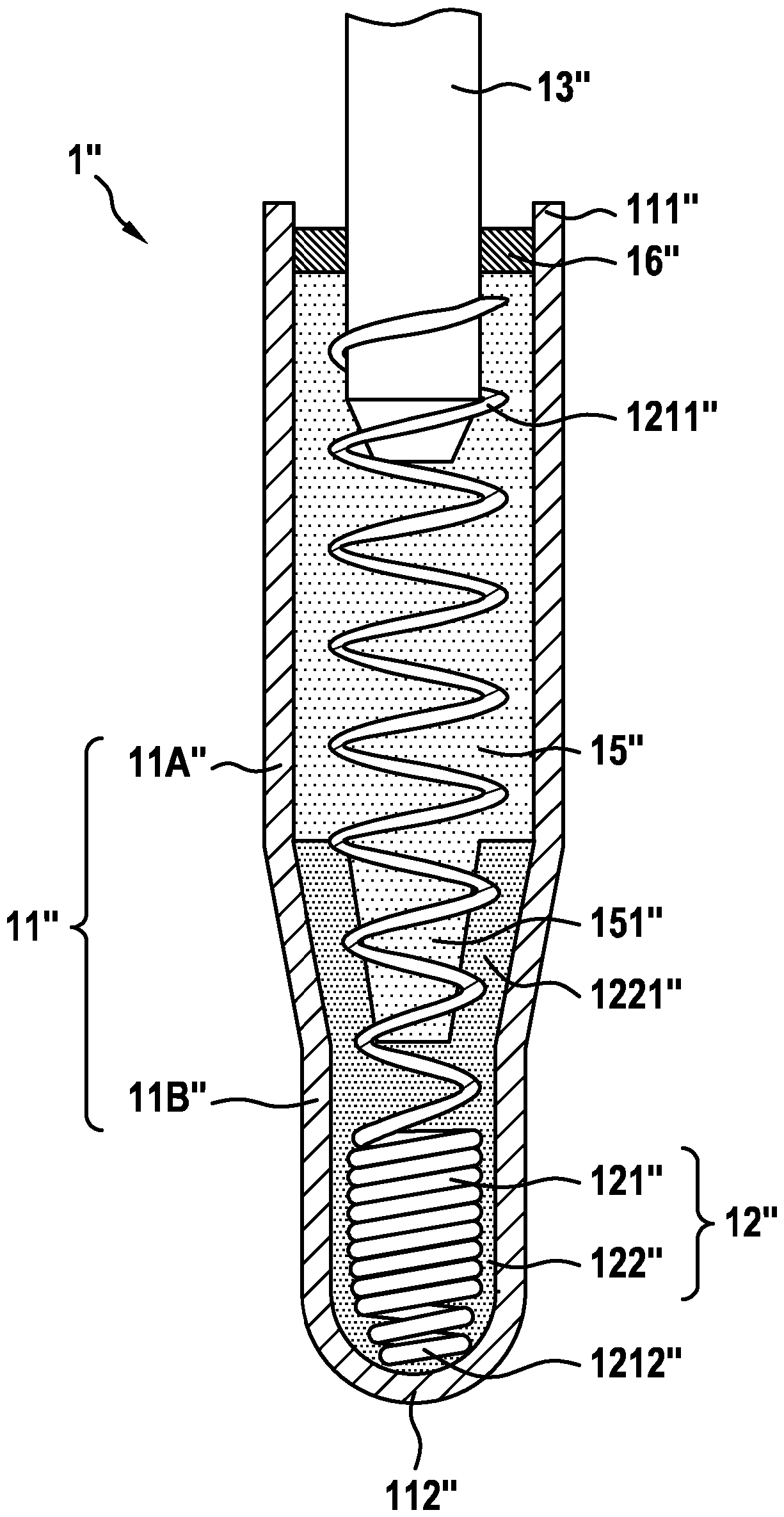

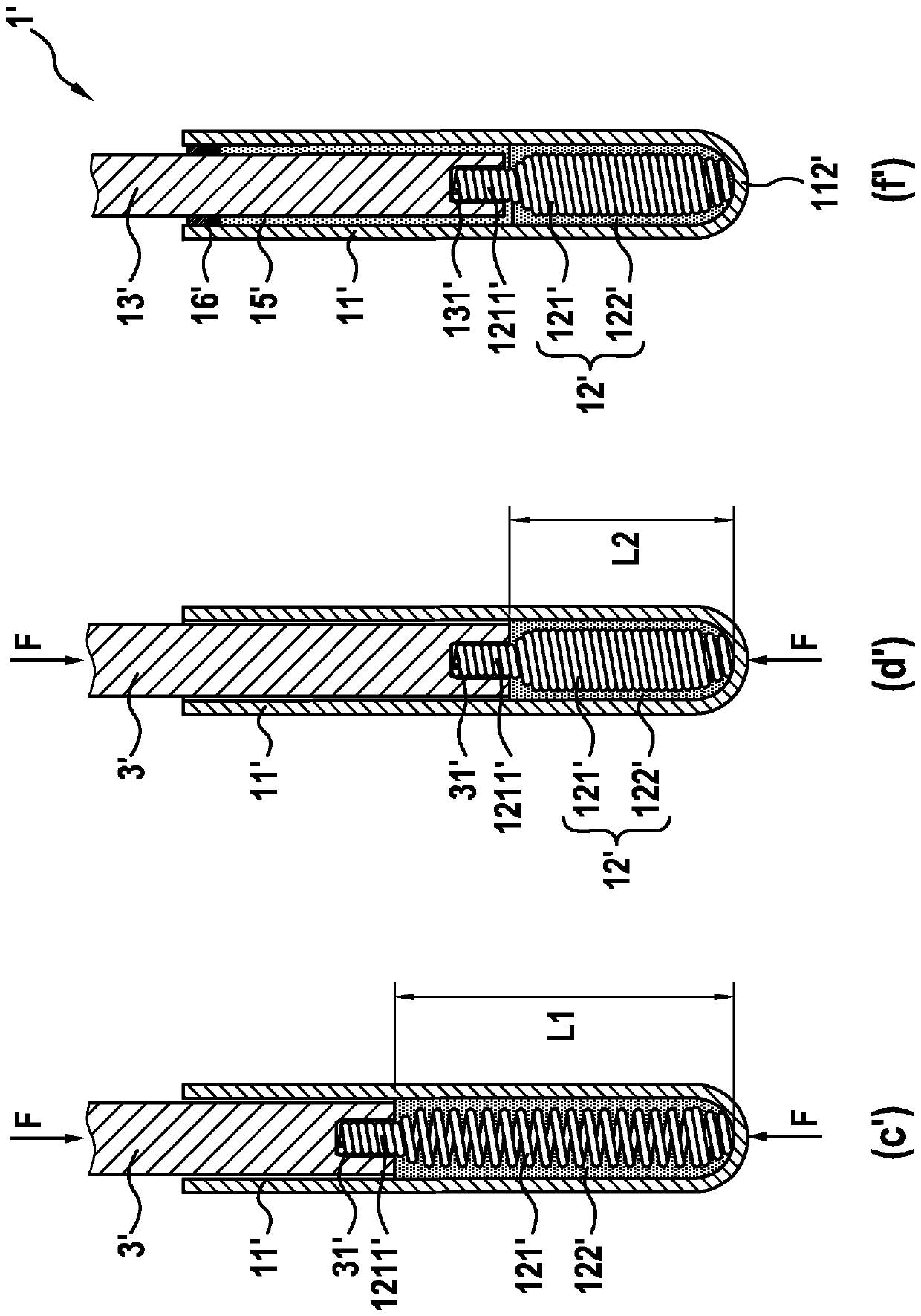

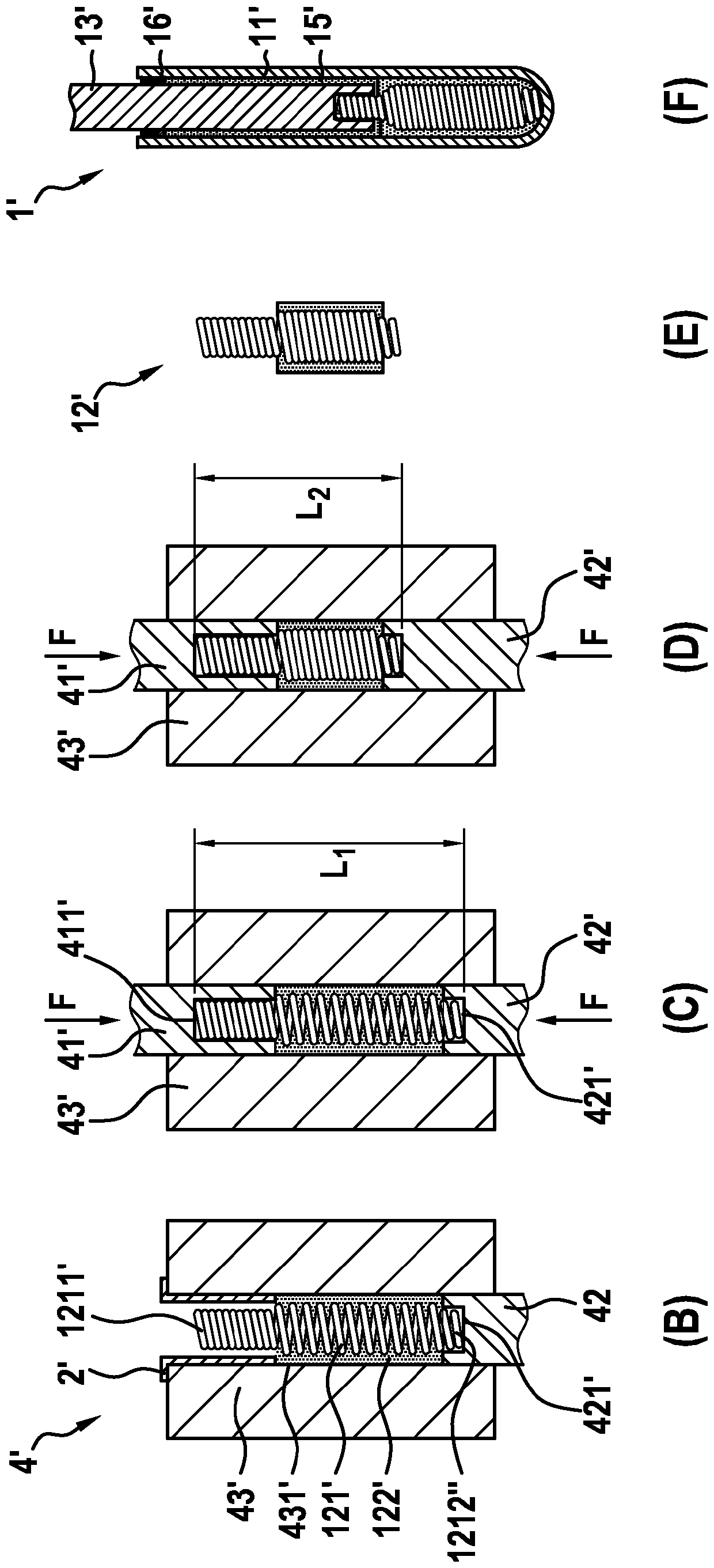

[0039] exist figure 1 A heating body 1 according to the invention for a glow plug according to a first preferred embodiment is shown in , in which components such as the housing as well as insulating components and coupling elements have been omitted for the sake of clarity. exist figure 1 The heating body 1 shown in has a metallic glow tube 11, a heating insert 12 arranged inside it (the heating insert is arranged inside the closed end 112 of said glow tube 11) and a coupling pin 13, which The coupling pin is connected to the heating insert 12 via the contact element 14 . The heating insert 12 and the coupling pin 13 are inserted into the glow tube 11 sideways from the open end 111 of the glow tube 11 , which end is opposite to the closed end of the glow tube 11 . The ends 112 are arranged opposite each other.

[0040] The heating insert 12 consists of an extruded composite from a coil 121 and insulating powder 122 . A first end 1211 of coil 121 , which is arranged oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com