Stuffed food machine

A food machine and stuffing technology, which is applied in manipulators, food science, baking, etc., to achieve high precision, improve automated production efficiency, and increase ornamental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

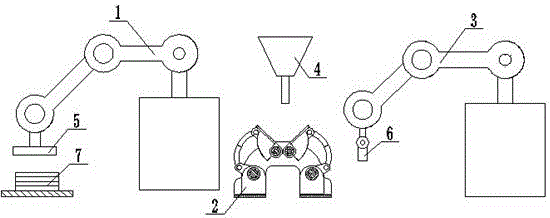

[0030] Such as figure 1 As described above, a stuffed food machine includes a wrapping device 2, and also includes a first mechanical arm 1 for placing the dough (7) in the wrapping device 2, a second mechanical arm for taking the stuffed food out of the wrapping device 2, Mechanical arm 3, the steps of encapsulating the stuffed food: the first step, the encapsulation device 2 is opened, the first mechanical arm 1 places the dough 7 in the encapsulation device 2; the second step, through the filling device 4 Filling is injected into the upper surface of the dough 7; in the third step, the wrapping device 2 is closed and the stuffing is wrapped in the dough 7 to form stuffed food. The second mechanical arm 2 is located at the bottom of the wrapping device 2 to support the dough 7 The lower surface of the lower surface; in the fourth step, the wrapping device 2 is opened, and the second mechanical arm 2 removes the stuffed food.

[0031] First, place the piles of dough 7 on the...

Embodiment 2

[0033] Such as figure 1 As described above, a stuffed food machine includes a wrapping device 2, and also includes a first mechanical arm 1 for placing the dough (7) in the wrapping device 2, a second mechanical arm for taking the stuffed food out of the wrapping device 2, Mechanical arm 3, the steps of encapsulating the stuffed food: the first step, the encapsulation device 2 is opened, the first mechanical arm 1 places the dough 7 in the encapsulation device 2; the second step, through the filling device 4 Filling is injected into the upper surface of the dough 7; in the third step, the wrapping device 2 is closed and the stuffing is wrapped in the dough 7 to form stuffed food. The second mechanical arm 2 is located at the bottom of the wrapping device 2 to support the dough 7 The lower surface of the lower surface; in the fourth step, the wrapping device 2 is opened, and the second mechanical arm 2 removes the stuffed food.

[0034] The first mechanical arm 1 is connected wi...

Embodiment 3

[0038] Such as figure 1 As described above, a stuffed food machine includes a wrapping device 2, and also includes a first mechanical arm 1 for placing the dough (7) in the wrapping device 2, a second mechanical arm for taking the stuffed food out of the wrapping device 2, Mechanical arm 3, the steps of encapsulating the stuffed food: the first step, the encapsulation device 2 is opened, the first mechanical arm 1 places the dough 7 in the encapsulation device 2; the second step, through the filling device 4 Filling is injected into the upper surface of the dough 7; in the third step, the wrapping device 2 is closed and the stuffing is wrapped in the dough 7 to form stuffed food. The second mechanical arm 2 is located at the bottom of the wrapping device 2 to support the dough 7 The lower surface of the lower surface; in the fourth step, the wrapping device 2 is opened, and the second mechanical arm 2 removes the stuffed food.

[0039] The first mechanical arm 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com