Processing technology of ultra-fine powder of Moringa oleifera leaves

A processing technique and Moringa leaf technology are applied in the processing technique field of Moringa leaf ultrafine powder, and can solve the problems such as large damage to color and fragrance, loss of effective components, loss of freshness in taste, etc., and achieve good drying effect and no loss of aroma. , The effect of keeping the taste fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0033] A kind of processing technology of Moringa leaf superfine powder, comprises the steps:

[0034] Step 1. Moringa leaves are cleaned and drained, and cut into uniform small pieces of about 10mm, and the small pieces of Moringa leaves are steamed at 100°C for 1-3 minutes;

[0035] Step 2, carry out vacuum drying to the leaves of Moringa oleifera after finishing by vacuum freezer, concrete steps are:

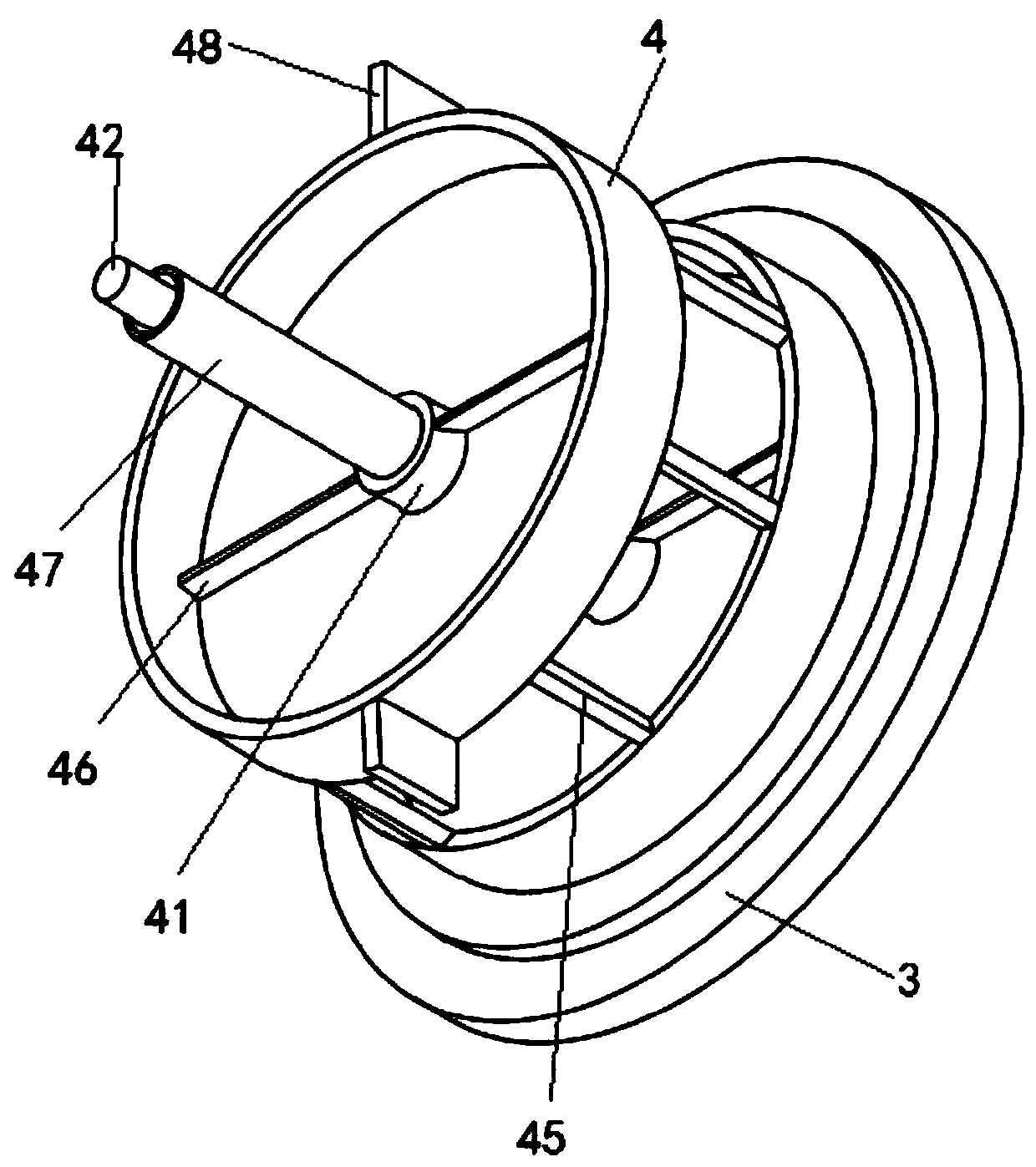

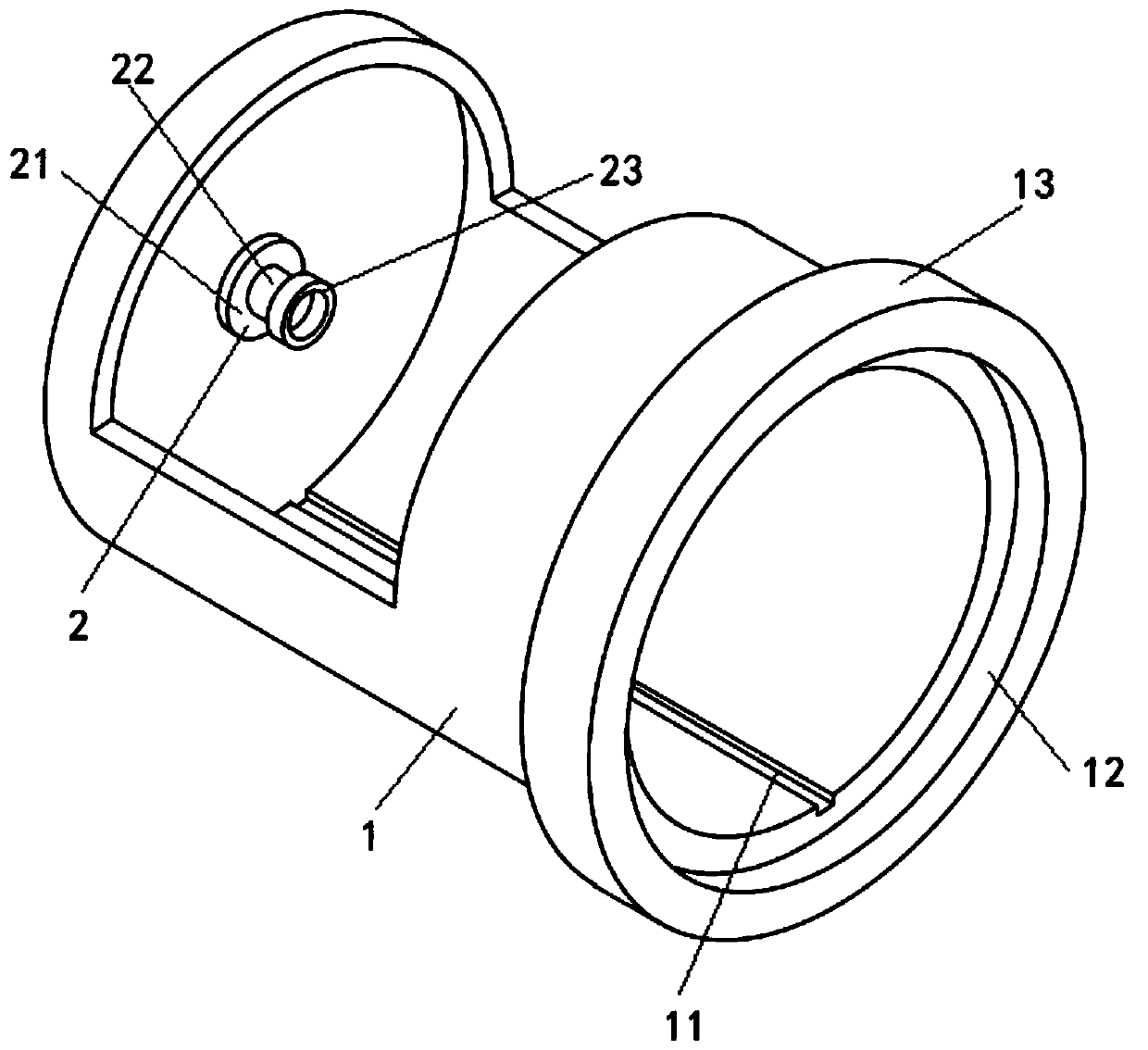

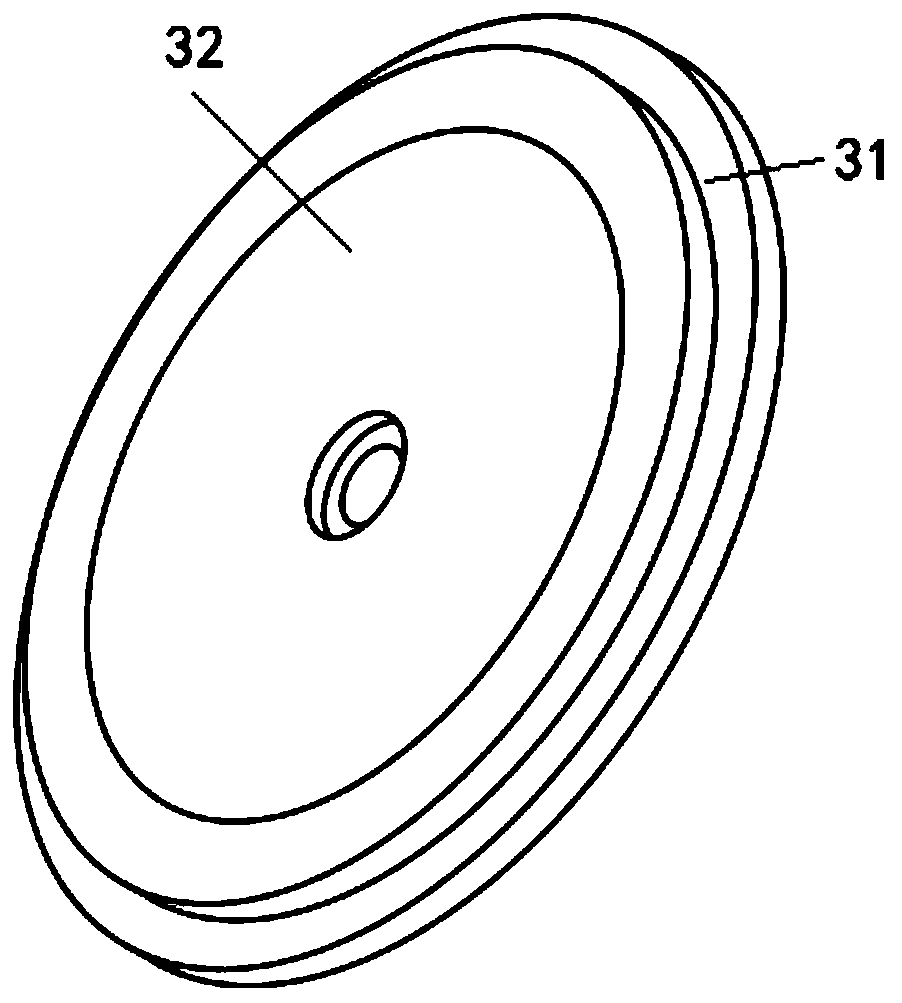

[0036] Pre-freezing, drive the carrier assembly through the driving cylinder to separate from the cabinet 1, add the finished Moringa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com