Processing technology of broccoli superfine powder

A processing technology, the technology of broccoli, applied in food processing, food drying, food science and other directions, can solve the problems of large damage to product color and fragrance, loss of active ingredients, loss of fresh taste, etc., to improve cleaning and processing efficiency, The effect of improving product quality and maintaining fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of processing technology of broccoli superfine powder, concrete preparation process is as follows:

[0032] In the first step, the fresh broccoli is cleaned and drained by a multi-stage combined cleaning machine, and then the drained broccoli is cut into uniform small dices of about 10 mm, and the diced broccoli is deenzymed (100° C. Steam, 1-3 minutes), and then sent to -18°C freezer for 3-5 hours, after freezing, into the vacuum freezer, after 12-18 hours of freeze-drying, control the freeze-drying temperature of the whole process below 50°C, blueberries The flower water can be out of the warehouse if the water content is below 8%;

[0033] In the second step, the freeze-dried broccoli is initially crushed to a fineness of 40-120 mesh by an ordinary pulverizer;

[0034] In the third step, the coarse powder after primary crushing is sent to the superfine pulverization unit for superfine pulverization to obtain 300-500 mesh fine powder products;

[0035] The fo...

Embodiment 2

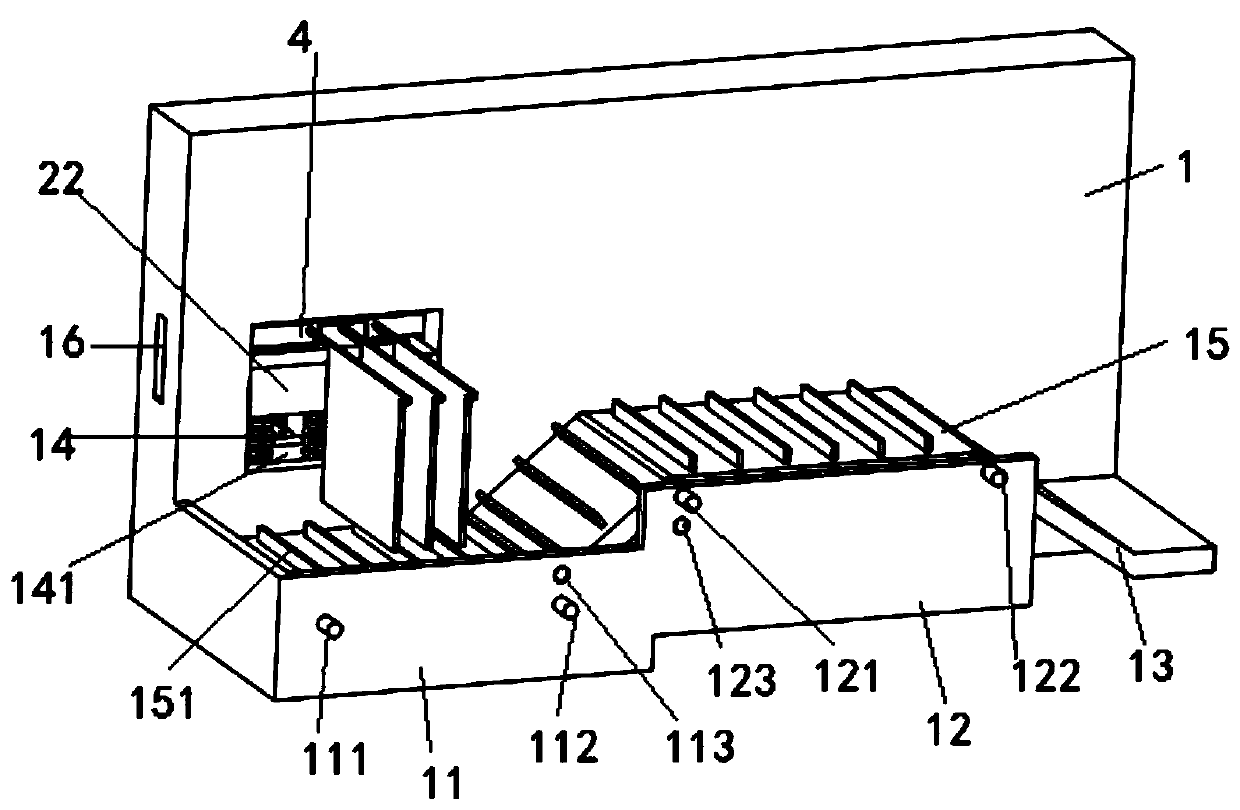

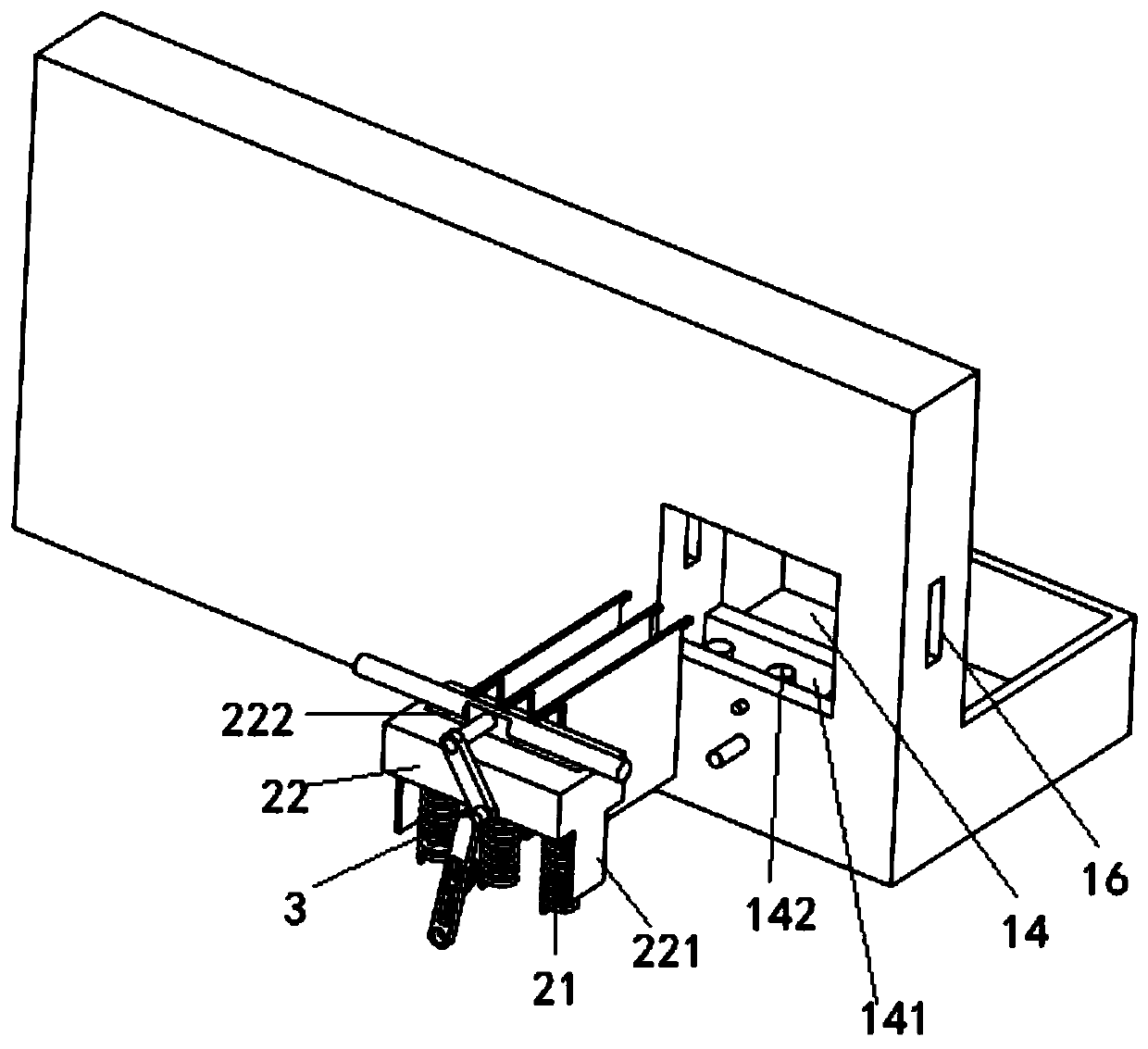

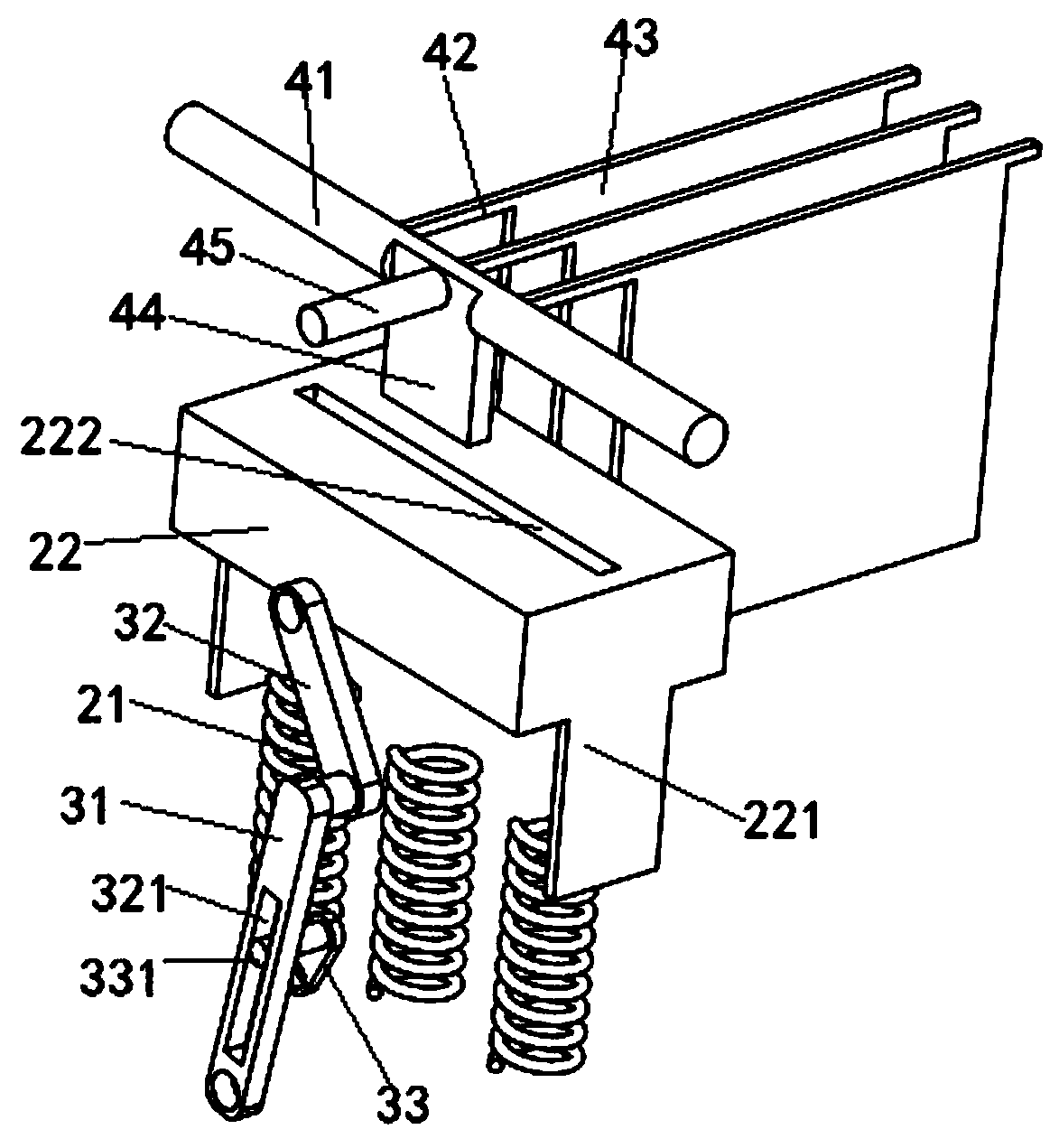

[0038] Such as Figure 1-3 As shown, the multi-stage combined cleaning machine includes a support plate 1, and the bottom of the support plate 1 is sequentially provided with a immersion pool 11, a rinse and drain pool 12, and a discharge buffer plate 13 from left to right; the side walls of the support plate 1 are respectively provided with There are high-pressure washing guns and drying fans, the high-pressure washing guns and drying fans are respectively located on both sides of the upper part of the washing and draining pool 12, and the high-pressure washing guns are located on one side of the immersion pool 11;

[0039] The bottom of the rinsing and draining tank 12 is located above the bottom of the immersion tank 11, and the bottom of the rinsing and draining tank 12 is located between the immersion tanks 11 and is provided with a water outlet. The water outlet is provided with a water valve. , the water is easy to get dirty, and the water in the washing and draining po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com