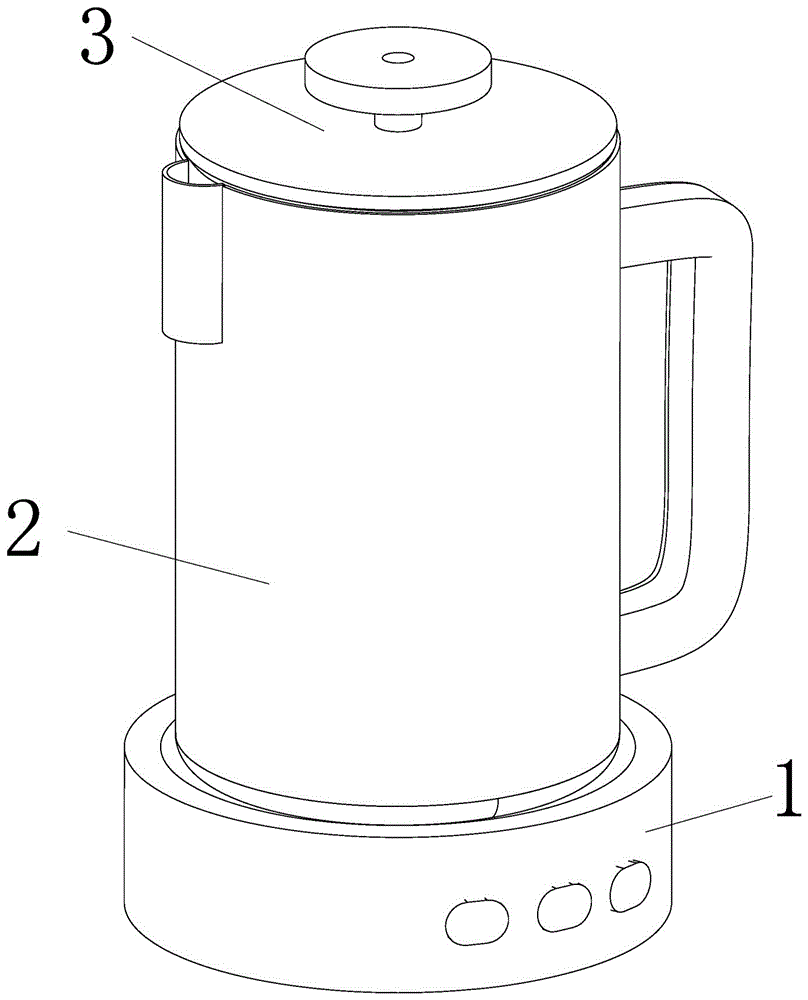

Full-automatic French press

A French-pressing, fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of cumbersome operation, manual removal, etc., and achieve the effects of ensuring drinking taste, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

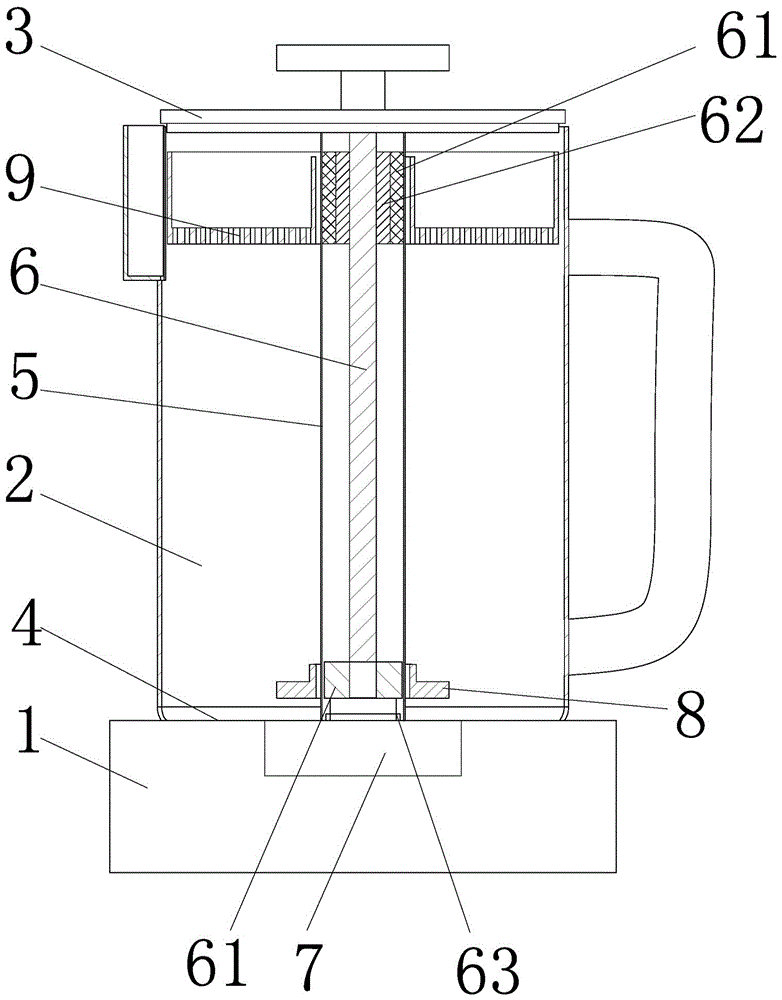

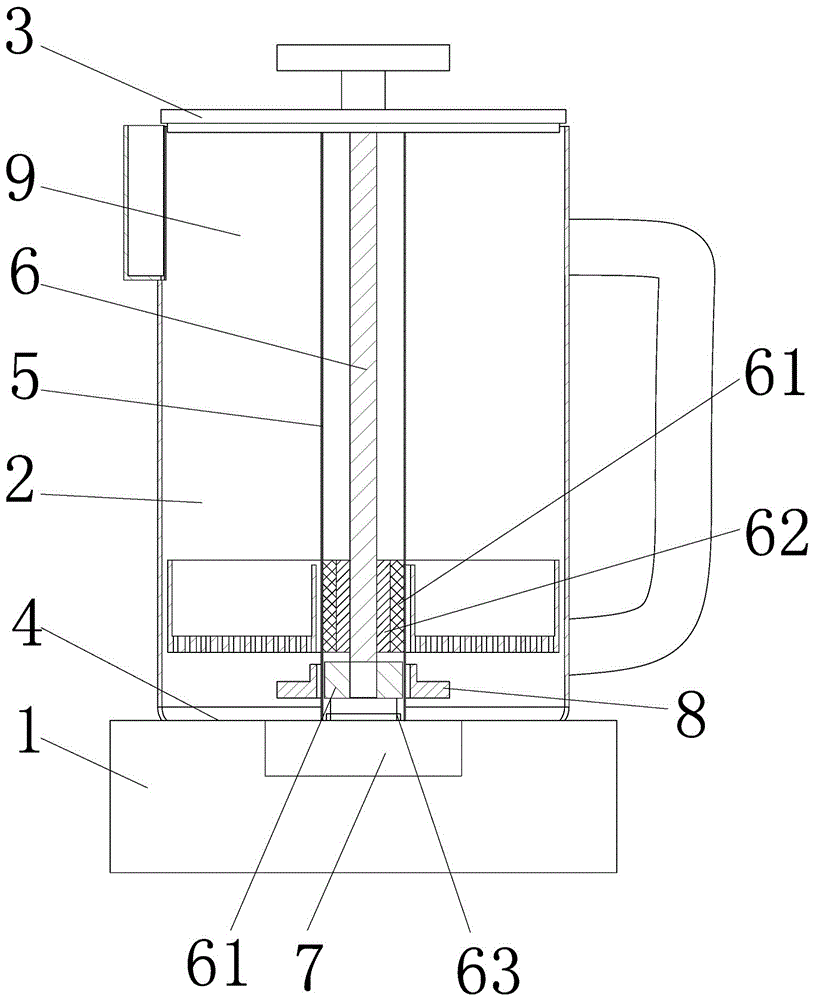

[0012] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A fully automatic French press pot, characterized in that it comprises a base 1, a glass pot body 2, a pot lid 3, a heating plate 4 is provided at the bottom of the glass pot body 2, and a vertically extending Guide tube 5, the guide tube 5 is provided with a screw rod 6 connected to the drive mechanism 7 arranged in the base 1, the bottom of the guide tube 5 is set with a stirring ring 8, the stirring ring 8 is connected to the screw rod 6 through the lower magnet mechanism Connected, when the screw mandrel 6 rotates, the stirring ring 8 is driven to rotate; the guide pipe 5 is also equipped with a filter screen 9, the filter screen 9 is connected with the screw mandrel 6 through the upper magnet mechanism, and when the screw mandrel 6 rotates, the upper magnet mechanism Drive screen pack 9 moves up and down.

[0013] Described lower magnet mechanism c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com